The full works

With the new development and continuous optimization of its packaging systems, saving on materials and energy in the process, KHS has been setting standards in the beverage industry for decades.

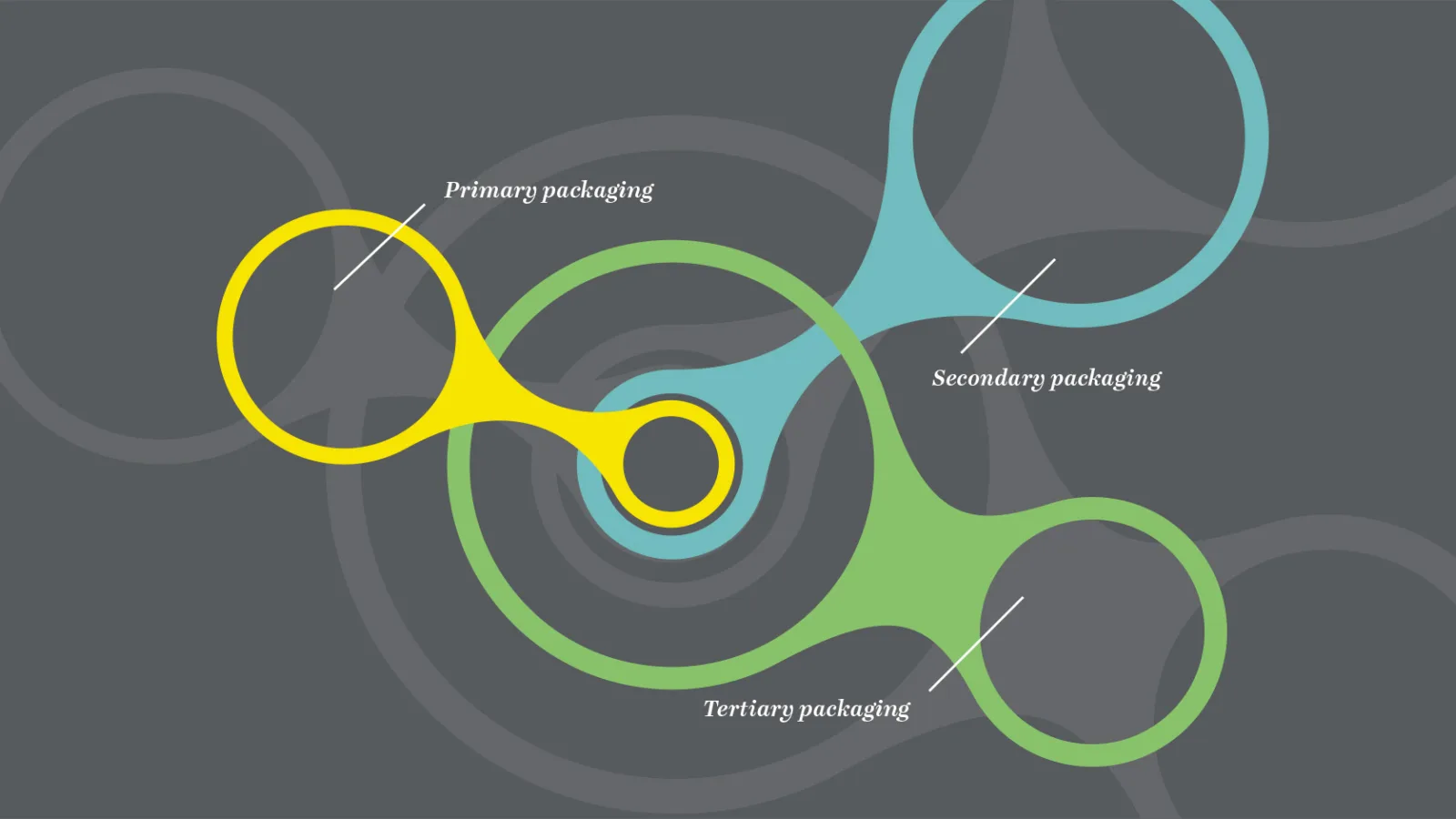

Primary packaging

For better hygiene and freshness

With a multitude of small improvements to its linear aseptic fillers, KHS has a big impact on efficiency, flexibility, ease of operation and product safety.

Click here for the article on: Much more

Secondary packaging

For less packaging material

Instead of shrink film KHS uses easy-to-remove dots of adhesive to fork PET bottles and cans into stable packs, thus saving up to 90% in packaging materials - now also in the high-performance range.

Click here for the article on: Full speed ahead!

Secondary packaging

For more flexibility in can packaging

Film, cardboard or paper - a new KHS packer provides all the options to cater for dynamic market and customer requirements and at the same time saves on energy and CO2 emissions.

Click here for the articel on: The all-rounder

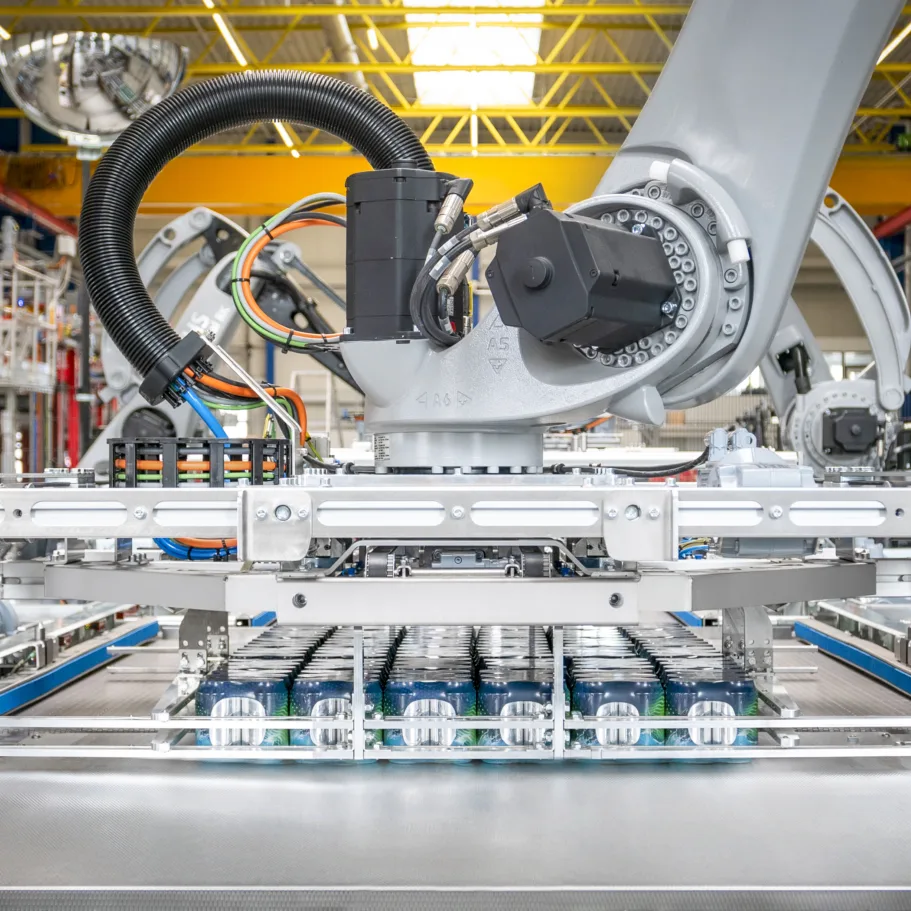

Tertiary packaging

For more efficiency in packaging and palletizing

KHS has used robots for palletizing for over 25 years: these high-tech systems master tasks such as sorting, distributing, depalletizing, palletizing and stacking quickly, simply and economically.

Click here for the article on: Colleague robot