New benchmark in energy savings

Near infrared radiation (NIR) and a unique Double Gate concept: state-of-the-art stretch blow molding technology from KHS exceeds the expectations of Coca-Cola in Knetzgau and generates considerable energy and cost savings.

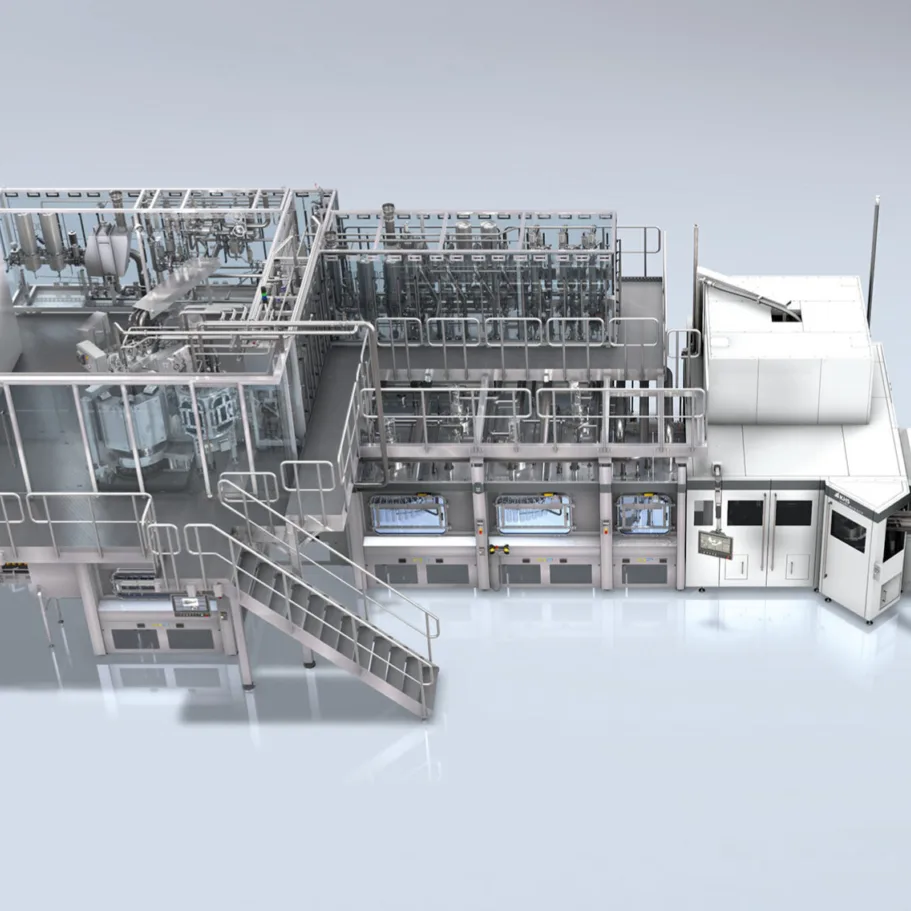

In the little town of Knetzgau in Lower Franconia stands one of the biggest Coca-Cola factories in Germany. Here, Coca-Cola Europacific Partners (CCEP) employs around 500 personnel, producing its popular classics Coca-Cola, Coca-Cola Light, Coca-Cola Zero, Fanta, Mezzo Mix and Sprite on a site measuring 200,000 square meters.

Focus on sustainability

In its striving to create a more sustainable future, the group has adopted a holistic approach. Saving energy, water and materials helps the environment and at the same time cuts costs. The Bavarian plant has now taken a further step in this direction by investing in a resource-conserving stretch blow molder from KHS.

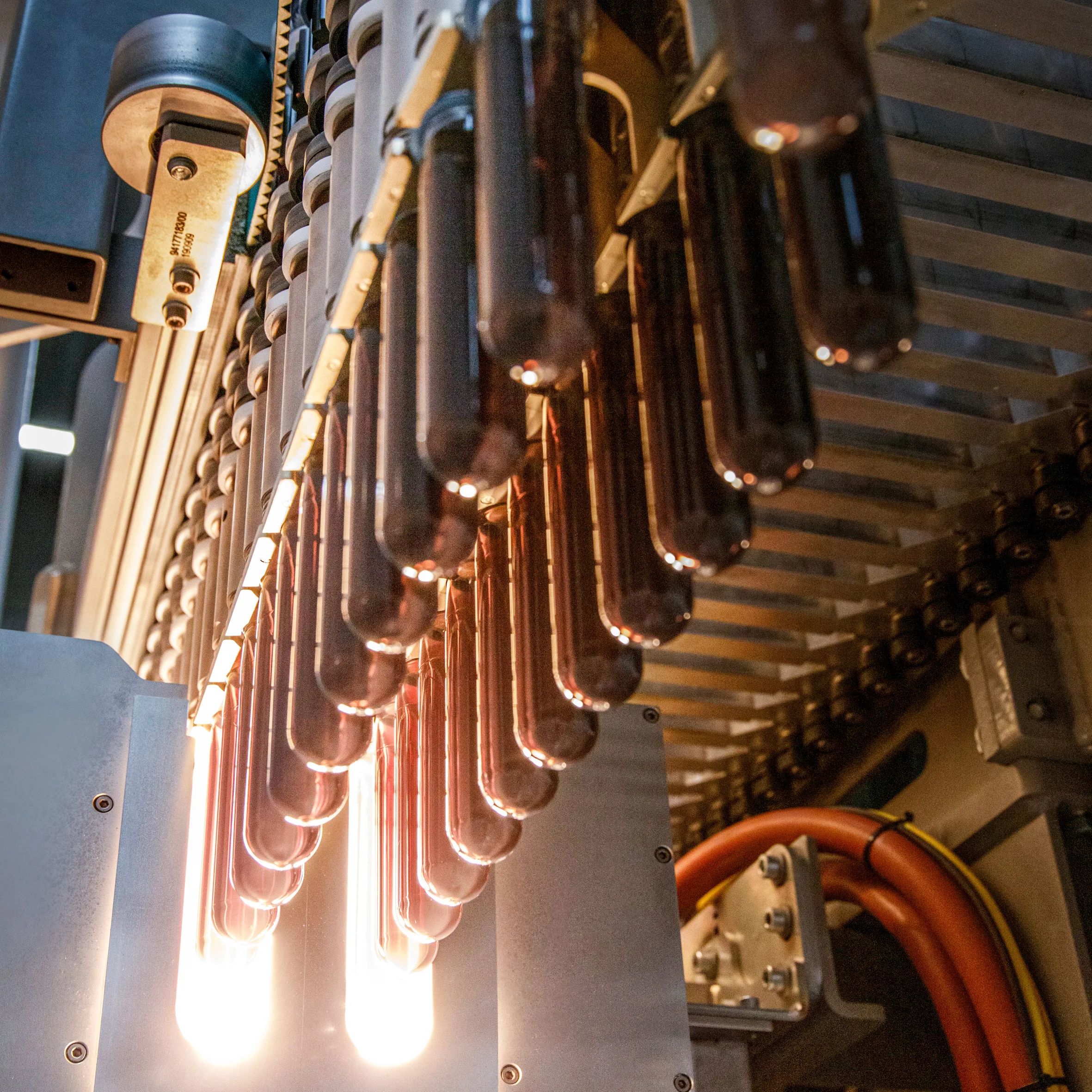

The unique Double Gate heating concept enables up to 40% in energy costs to be saved compared to single-lane stretch blow molders of the same capacity.

Much lower energy consumption

The latest generation of the proven InnoPET Blomax isn’t just distinguished by its high performance; it also scores in direct market comparison above all with a high level of energy efficiency. Two specific measures help to achieve this: firstly, the PET preforms are heated by near infrared radiation (NIR). This in itself is far more efficient than many of the infrared heaters often installed. Secondly, the InnoPET Blomax conveys the preforms without primary reflectors on both sides of the lamps, enabling their energy to be applied much more effectively. What’s more, this Double Gate, as it’s known, is more compact than standard preform heaters.

Knowledgeable decision

In Knetzgau, two stretch blow molders manufactured in 1998 were to be replaced. They no longer satisfied the company’s requirements regarding energy consumption and the availability of spare parts. Project manager Ralph Sauter spent a long time deliberating over the investment in advance, comparing various systems before deciding in favor of KHS.

Powerful: in Knetzgau the InnoPET Blomax produces up to 20,000 2.0-liter containers an hour and a maximum of 30,000 bottles an hour in the 1.5-liter format.

Outstanding savings

“KHS’ new Double Gate technology and the savings this makes were of great interest to us,” says Sauter. Following its successful acceptance, the machine has been up and running for a few weeks now. Sauter reckons on saving up to 560,000 kWh of electricity per year – an impressive figure in the face of constantly rising energy prices. “All suppliers have understood the importance of this issue,” he believes, “but compared to other systems on the market, KHS convinced us with its much higher savings.”

“We’re impressed by the functionality and performance of our new machine,” he adds. “The Blomax processes 20,000 2.0-liter containers and 30,000 1.5-liter containers an hour. As it’s so flexible, we can perfectly integrate it into our line.”

“Our high expectations of the InnoPET Blomax’ performance were actually exceeded.”

Project manager, Coca-Cola Knetzgau

Challenges mastered

One particular challenge was posed by the existing bottle air conveyor, the project manager continues. It had to be adapted to service not the previous two machines but instead just one. As its position was fixed, the new system had to be aligned in the bottle shop with centimeter accuracy. This is confirmed by Marc Harald Eysel, sales manager for PET Technology at KHS. “This was an exciting task for us. However, for KHS, adjustments like these in the interests of the customer are a matter of course. After all, we don’t just want to convince our clients with our system performance alone.”

While requirements in Knetzgau have initially been met by the new investment, in other places the demand for energy-cutting technologies such as the Double Gate is on the rise. “Even compared to more modern stretch blow molding systems installed up to the end of the last decade, our machinery clocks up further savings of up to 30%,” Eysel concludes.