Getting to grips

Totally without plastic film and thus twice as ecofriendly: the unique Nature MultiPack from KHS can now be combined with a simple and practical carrying handle made of cardboard.

In view of increasing climate change, both consumers and legislators are demanding that industry and commerce come up with more environmentally-friendly and more sustainable forms of packaging. There’s thus a considerable interest in systems that provide this – even more so if the benefits prove both ecological and economical. After all, the use of less material also means a cut in packaging costs.

Lowest possible consumption of materials

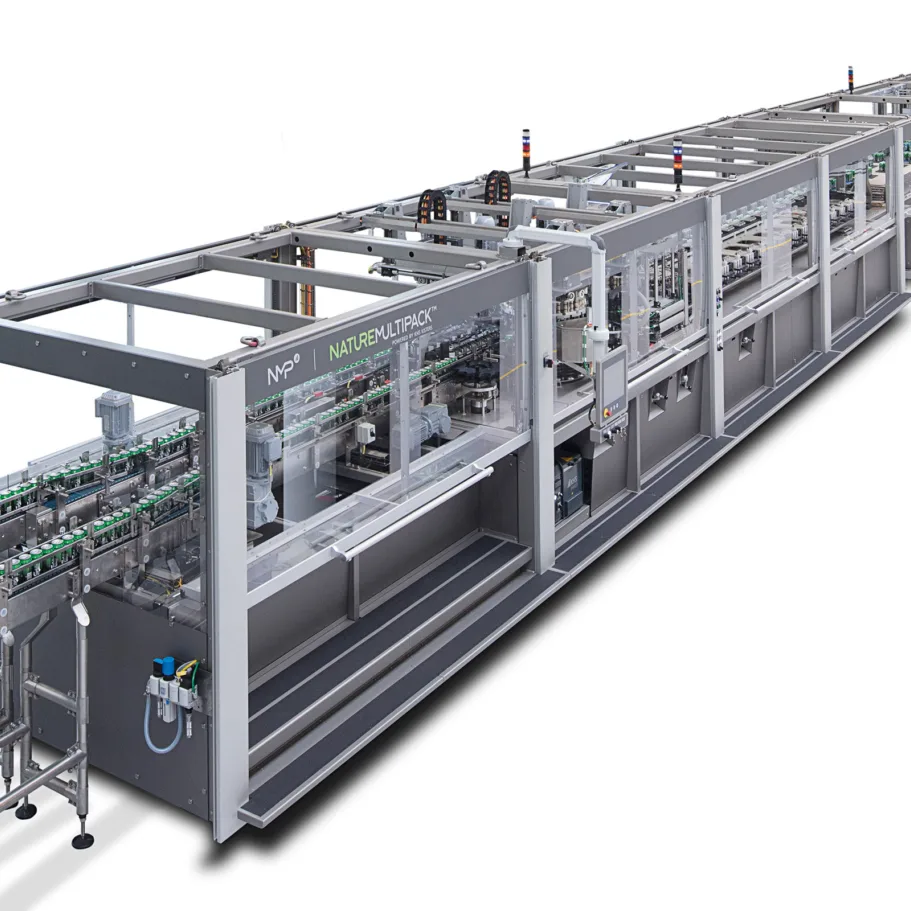

One outstanding example of climate-friendly packaging in the beverage industry is the unique Nature MultiPack by KHS: in place of shrink film, paper or cartons, here just a few dots of adhesive are required to turn PET bottles and aluminum cans into packs. This means that 85% less material is consumed compared to conventional setups. Furthermore, in the best instance just one third of the energy is needed for production.

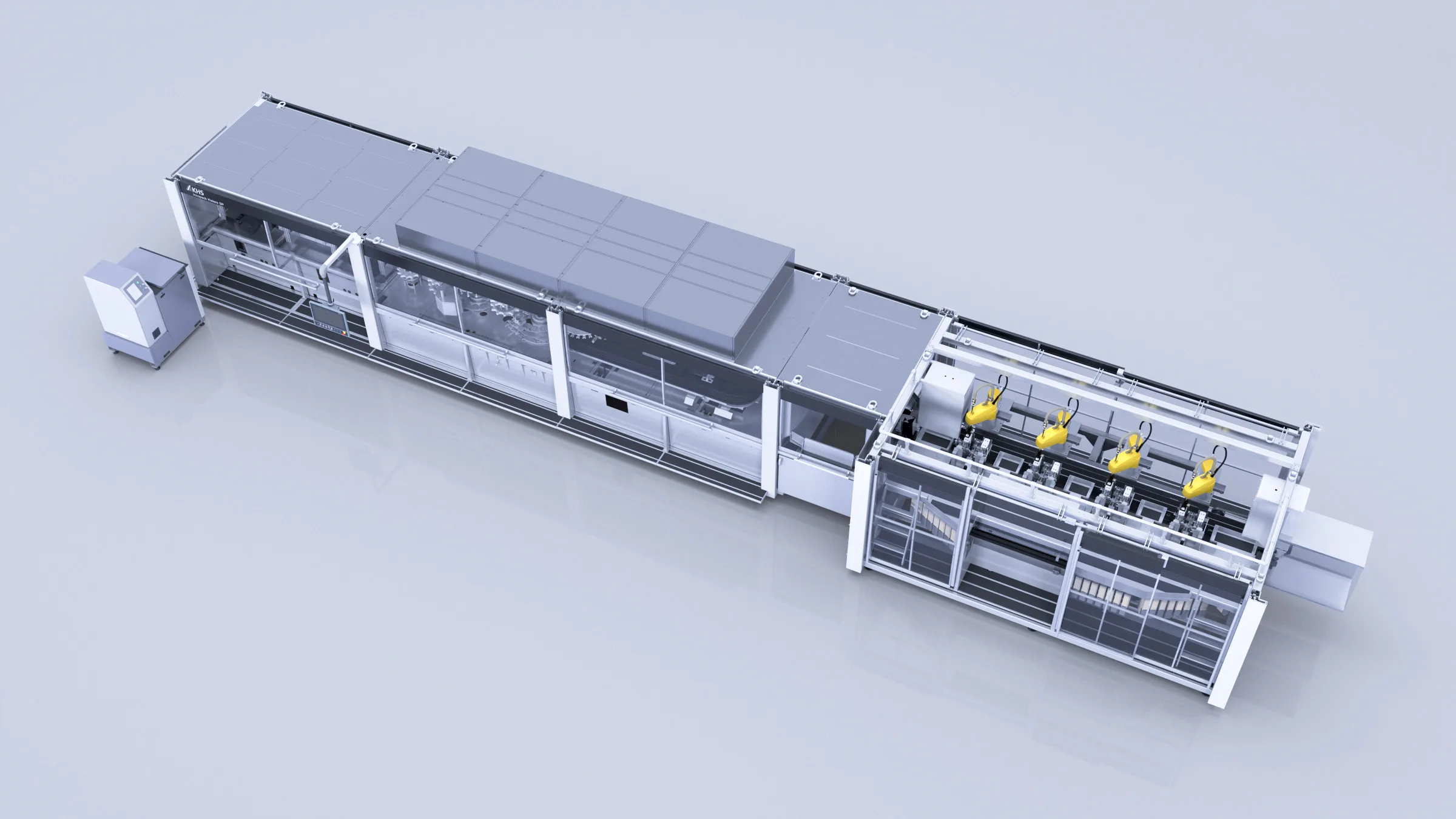

The Innopack Kisters NMP joins bottles together with dots of adhesive to form packs before robots apply the carrying handle in alternation.

The carrying handle is applied by the robot – regardless of how many containers the pack actually contains.

Minimalist addition

So that a Nature MultiPack can be fabricated and taken home by the consumer without any plastic having to be used, KHS has now combined it with a further ‘minimalist’ feature: what’s known as the BottleClip Carrier made of kraft paper has now been developed in close cooperation with the Hinojosa Packaging Group, a leading company in the design and manufacture of sustainable packaging solutions. The comfortable carrying grip is slotted onto just two bottles in the pack, regardless of how many this actually contains. Here, two pre-punched and folded tabs are erected and hooked under the ring on the bottle neck. This ensures that the carrying handle sits firmly and can be safely transported – whatever the number and volume of the containers in the pack.

Comfortable grip

Especially when handling heavier packs, conventional handles made of plastic film often cut into the shopper’s hands. The cardboard carrying handle is far more pleasant to grip and transport. When the consumer picks up the pack by the BottleClip Carrier, its long sides bend upwards. This protects sensitive palms from sharp punched edges and bottle caps. Once home, the cardboard grip can be easily removed and recycled in the paper bin.

Great flexibility

Flexibility is writ large regarding both the packs and the cardboard carrying handle. Pack sizes of two to eight PET bottles containing 250 milliliters to two liters are possible. “We’ve made sure to create a uniform look and feel for all sizes,” says KHS project manager Manfred van Triel. “Minimal adjustments have been made to the respective punching dies to suit the bottle diameter and volume and ensure the best possible functionality.”

“It’d be hard to find a multipack on the market at the moment that uses less material.”

project manager, KHS

Thoroughly tested

KHS has designed the clip in an iterative process with its partner Hinojosa that specializes in sustainable food and beverage packaging solutions. “Together with KHS, we progressively tested what works and where we needed to make improvements,” says Vitor Coelho dos Santos, head of Business Development for Offset Packaging at the Hinojosa Packaging Group. “Our engineers carried out extensive pack life cycle tests with our colleagues from KHS. These involved consumer handling tests under the influence of high humidity, for example, plus wide-ranging logistics tests including palletizing and transportation.” All told, it was an extremely constructive process, during which the various parameters were constantly optimized.

The result is a carrying handle made of cardboard that’s large enough to include product information and the multipack barcode – but at the same time as small and as stable as possible. “We believed it was important to find a shape that’s as simple as possible for application in the packer,” emphasizes van Triel. “What good is the best solution if it’s so complex that it can’t be quickly and easily processed on our machines?”

“Together with KHS, we constantly optimized the various parameters in an extremely constructive process.”

Head of Business Development für Offset Packaging, Hinojosa Packaging Group.

Reliable processing

Great importance was thus attached to devising a sophisticated logistics process. The BottleClip Carrier is supplied in cartridges or secondary cartons that can be easily fed into the machine magazines in a loading process. “This is crucial to the performance of the system,” van Triel explains.

Not only is there less operator involvement and material consumption; the amount of space needed is also reduced. The new application module specifically saves up to four meters in machine length in direct comparison to a machine that processes conventional film carrying handles – an especially pertinent argument for beverage producers with limited production space.

The interest being shown by the industry in the new equipment is considerable, with the first projects already in preparation. This comes as no surprise to van Thiel. He’s convinced that it would be hard to find a multipack currently on the market that uses less material.