Done everything right

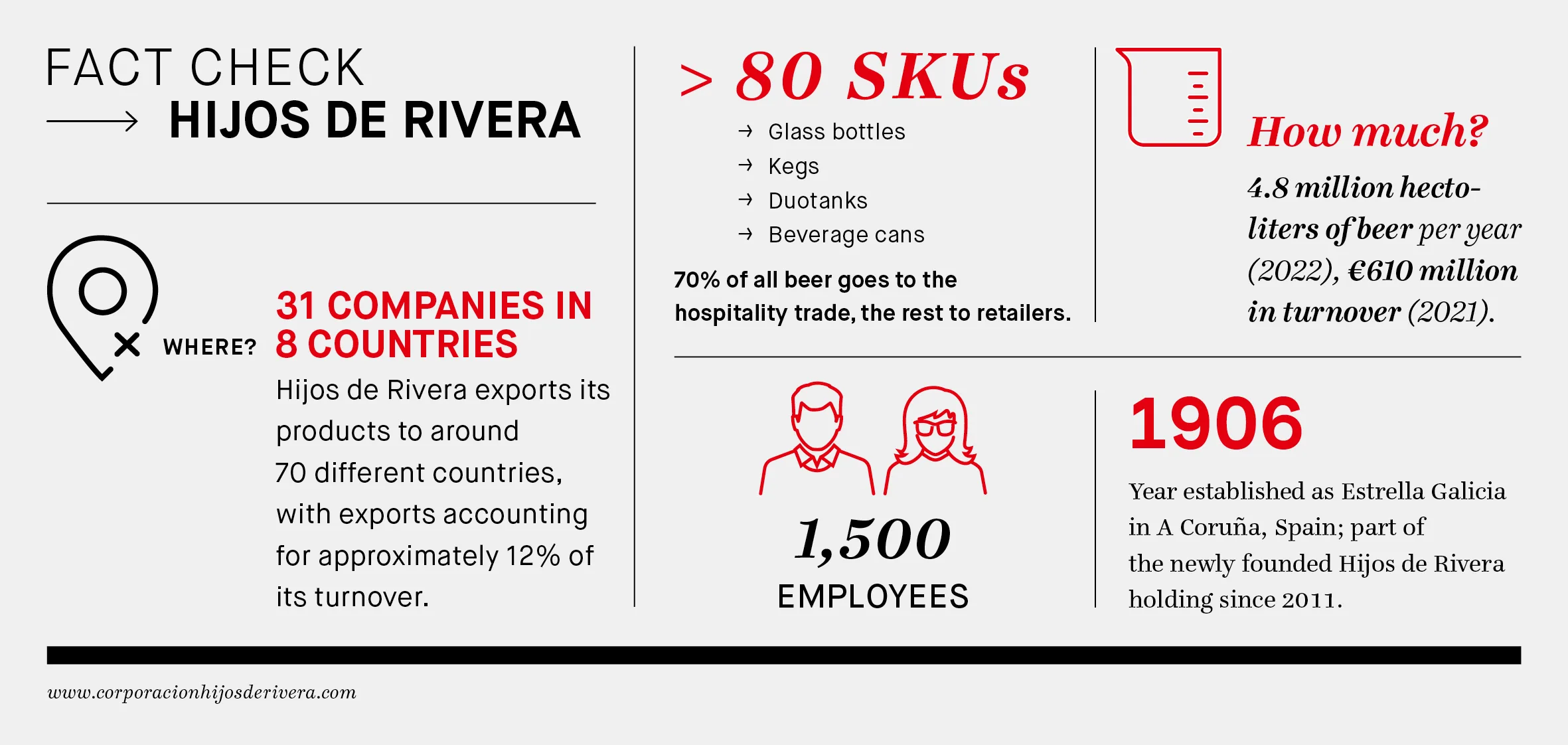

In its beverage can growth segment traditional brewery Estrella Galicia recently procured not one but two clever Nature MultiPack systems from KHS. In doing so, the company has gone for innovative technology and a reliable partner – not for the first time and certainly not for the last!

In the far northwest of Spain lies the region of Galicia. It’s famous not only for its capital of Santiago de Compostela, a place of pilgrimage and final destination on the Way of St. James, but chiefly for its climate: nowhere else on the Iberian Peninsula does it rain as frequently and as much as here. In strong contrast to the rest of the country, some of it plagued by drought, the green hills, regular mist and often stormy winds are reminiscent of the Irish coast. Farming and fishing are therefore both important here, with the Galicians especially proud of the variety and quality thereof. This is also what Jesús Martínez Garcia confirms, plant manager for beverage producer Hijos de Rivera. “In our region we’re very conscious of the importance of the origin of our products, of the passion and creativity that goes into them and the demand for quality when it comes to asserting yourself on competitive markets,” he says. “The high appreciation consumers have for Galician produce is based on a long manufacturing tradition for high-quality produce.”

Estrella Galicia, the flagship of the family-run business based in the port of A Coruña, benefits from this horn of plenty. The fourth-largest brewery in the country is famous for its light, golden beer made of particularly bitter malt and hops. It takes over 20 days to brew, ferment and mature, thus lending the beer its pleasant, characteristic hoppy note. The company is also distinguished by its great willingness to experiment, as master brewer Luis Alvar proudly states. “Each year we brew three or four specialties as limited editions to test their acceptance among consumers. In the past we’ve flavored our beer with chestnuts, pumpkin or honey, for instance, and even with goose barnacles. For one of our milk stouts we laced the beer with milk from cows fed with spent grain*. And our pimientos de Padrón beer that we add small, local, sweet peppers to is a real hit.”

* Spent grain = the residue from the brewing malt produced during beer production that can be used industrially or as animal feed.

One of the two packaging machines on the new canning line from KHS is an Innopack Kisters NMP for the high-capacity range.

Both modern and traditional

The special beers crafted under the name of “fabrica de cerveza” are just one of many examples for the company’s claim to premium quality. “As opposed to the big industrial breweries of Spain, despite our recent rapid growth in size we still see ourselves as a traditional company,” Alvar stresses. “We use cutting-edge technology but always with recourse to classic methods. We’ve drawn a number of red lines in the brewing process that we don’t cross, for instance. And for us, quality always takes precedence over quantity or speed: producing a good product simply takes time – and we give ourselves this.”

»In our opinion, their high level of innovation makes KHS systems among the best in the world.«

Plant manager, Hijos de Rivera

In 2019 MEGA was opened on the brewery premises, a world of experience plus museum and events location devoted entirely to beer culture. This is where Hijos de Rivera tells the story of the company and pays tribute to the family of owners by celebrating their innovative culture and experiences but also their battle against the increasing uniformity of beer. This is also where concerts, festivals and exhibitions are held that regularly attract a large audience.

Besides its commitment to innovative products, the lager marketed under the Estrella Galicia brand continues to be the brewery’s top seller, with Estrella Galicia aiming to sell an impressive almost five million hectoliters of beer in 2023. Thanks to an upward trend that’s way above the average for the rest of the country, the company is clearly on course for success – and sees considerable potential for growth in the future, too. After all, for a few years now the amount of beer consumed in Spain has steadily increased.

On course for further growth

Accordingly, its plans are no less than ambitious: as the existing Agrela production site in A Coruña is at the limits of its capacity with nine filling lines, the brewery is currently investing in a new plant ten kilometers away from the present location. An area covering a total of 500,000 square meters will soon be available that will provide plenty of room for further expansion. One of the key technology suppliers to Hijos de Rivera is Dortmund engineering company KHS. To date, the machine and systems manufacturer from Germany has delivered no fewer than five lines for glass, beverage cans and kegs to A Coruña. “For us, KHS has been one of our most important partners for many years,” claims Martínez. “We particularly like their high level of innovation which in our opinion makes KHS systems among the best in the world.” One of the most recent joint projects is a turnkey canning line, for example, with a capacity of up to 72,000 containers per hour. The system has two packaging machines. One of these is an Innopack Kisters Nature MultiPacker for the high-capacity range, on which beverage containers are turned into packs of four or six using easy-to-remove dots of adhesive without the need for any film or cardboard. The other is an Innopack Kisters TSPP that has a paper-wrapping module that packs 12 to 24 containers in perfectly folded and glued paper instead of in shrink film. The purpose of both packers is to provide optimized systems that consume as little material as possible and at the same time significantly reduce the packaging’s carbon footprint. In parallel, an existing KHS canning line with a maximum output of 60,000 containers per hour was also expanded to include an Innopack Kisters Nature MultiPacker.

Overview of the new canning line from KHS: in the background are the pasteurizer and filler, in the center the two packers and in the front of the photo is the palletizing setup.

In the orientation module the beverage cans are rotated in a matter of milliseconds until they are aligned as required.

More information on our innovative and resource-conserving Nature MultiPack packaging system can be found on khs.com.

Unique packaging system

“Traditionally, we’ve always packaged our beverage cans in cartons so that we don’t have to use any plastic,” explains Garcia. “In view of the current debate on packaging and the environment, our competitors are now also increasingly doing away with film or hi-cone packs and instead using cardboard. In this context, we find it important that the packaging systems used for our products continue to be unique on the market. This is why we’ve gone for Nature MultiPack – a real first on the Spanish market.”

Hijos de Rivera supported the launch of the new, sustainable alternative with an extensive marketing campaign. Under the motto of “the best packaging is the one that isn’t there”, the Estrella Galicia six-pack is sold as a NoPack. Thanks to advertising in the form of eye-catching videos chiefly posted on social media channels that showed consumers how to handle the packs, the new system has been outstandingly well received on the market. “We have had lots of absolutely excellent feedback,” smiles Garcia. “Consumers are specifically asking for the NoPack which for them is both an attractive and environmentally- and climate-friendly variant. The most important thing, however, is that we can gage our success not just through our high media presence but also by looking at our sales figures: since the launch our market share has clearly increased.”

»Despite cutting-edge technology, for us quality always takes precedence over quantity or speed.«

Master brewer, Hijos de Rivera

Consistent branding

The generally high brand awareness of Estrella Galicia is the result of widespread sponsoring measures that the company consistently implements in many different areas. Activities it supports include Formula 1, MotoGP and soccer – as sponsor of the local club and several teams in Spain’s Primera División, among others – and countless major music festivals up and down the country. The brand is also everywhere in its home town of A Coruña: from house facades in the city center to the control tower of the local airport. What’s more, the Cuatro Caminos beer bar in the middle of an old factory complex boasts the highest beer sales in the whole of Spain. The marketing ploy is so successful that it has attracted a number of imitators. “We’ve strengthened the brand, its values and its identity with our strategy and forged a close bond with the consumer,” Garcia states.

The Innopack Kisters TSPP paper wrapping module wraps beverage cans in perfectly folded and glued paper instead of plastic film.

The paper-wrapped packs cater for a rapidly growing consumer demand.

Pledged to provide premium quality, the brewery isn’t satisfied with simply investing in high-profile advertising but also wants to set a good example. “An important part of our activities focuses on saving resources and reducing our carbon footprint,” the plant manager emphasizes. “This was one reason why we again chose KHS to supply our most recent canning line. The systems provider not only scored points with us for its line layout but also by having the lowest energy consumption on the market. We not only implement particularly energy-efficient technologies but also use methods designed to recover energy. And we think long and hard about the packaging of our products: how can we save even more material? Which materials are recyclable, have a positive ecobalance and at the same time are economically sustainable?” Besides using secondary packaging such as Nature MultiPack or the KHS PaperWrapper, Estella Galicia is thus increasingly opting for the beverage can as its primary packaging of choice. “We’re convinced that this type of container will play an increasingly bigger role thanks to its excellent recyclability and simple handling for consumers,” finds Garcia.

Reliable partner

“In KHS we definitely have the right technology partner at our side to take us through this development,” production director Carlos Bao believes. He particularly appreciates the smooth coordination and cooperation between the project team on the one hand and installation and commissioning personnel on the other. Above all, the local service and support provided by the regional Spanish office are of prime importance to him. “We’re extremely pleased with our new system and especially with the packaging equipment. If you want to be a pioneer, it’s good to know that you can rely on your partners 100%. In this respect, we’ve done everything right.” And so that this stays this way in the future, too, the Dortmund engineering company has now received orders for two more turnkey lines with a respective upper capacity of 72,000 non-returnable glass bottles per hour – in perfect time for the move to the new brewery.