Full speed ahead!

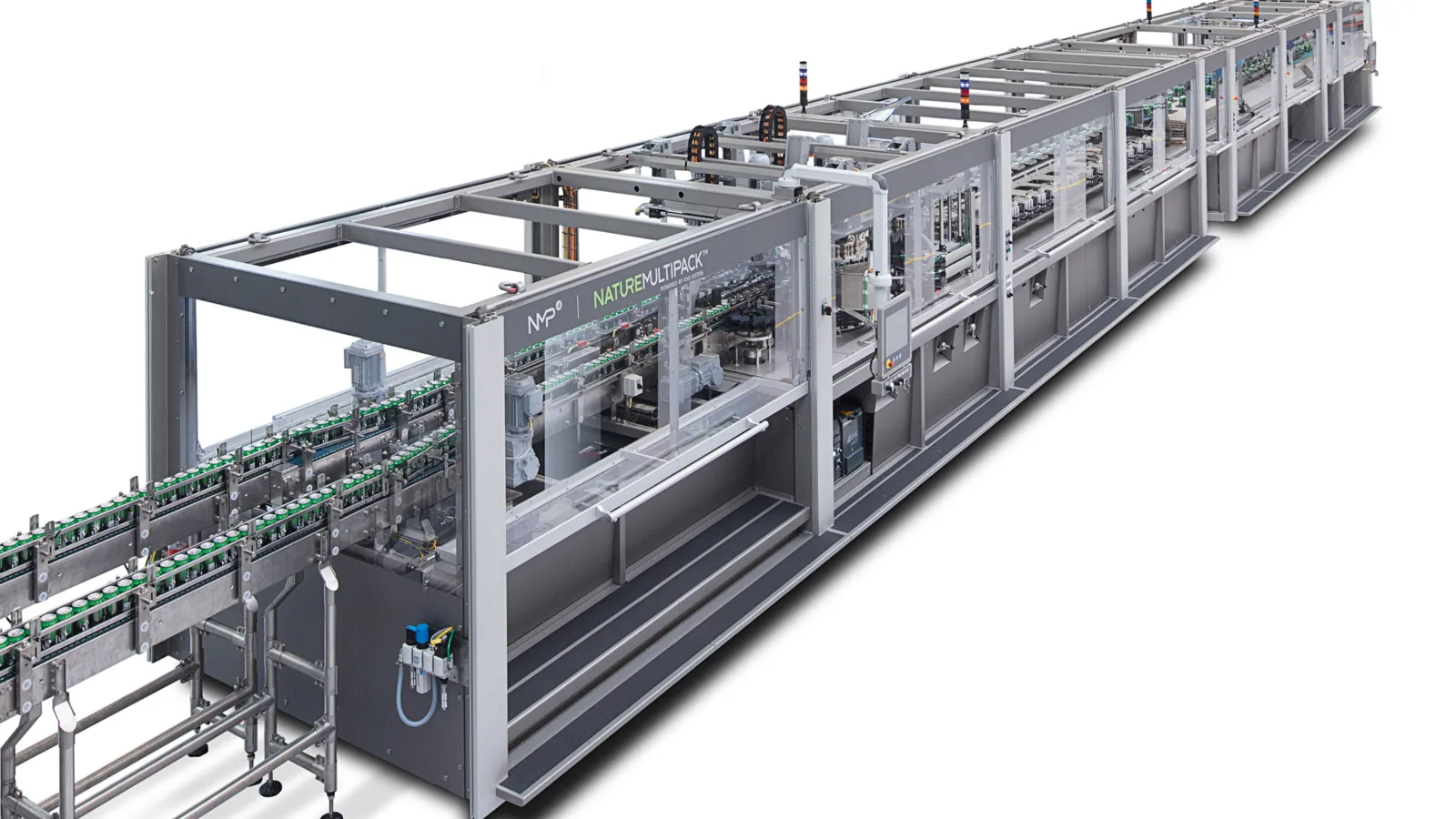

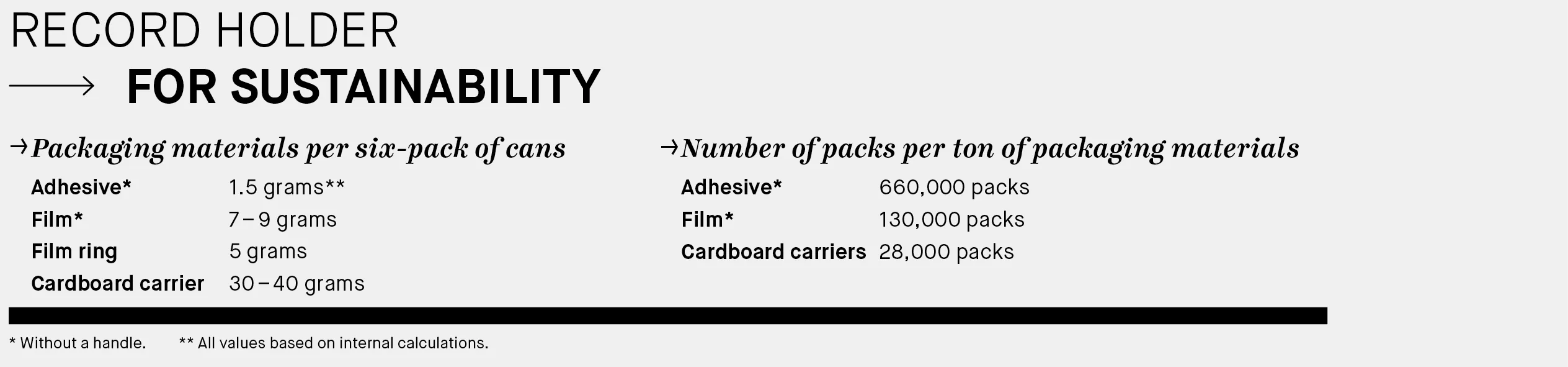

Nature MultiPack™ from KHS combines containers not with shrink film but with easy-to-remove dots of adhesive to form stable packs, thus saving up to 90% in packaging materials. One of the most sustainable packaging innovations to emerge in the past few years, this system is now also available for the high-performance range.

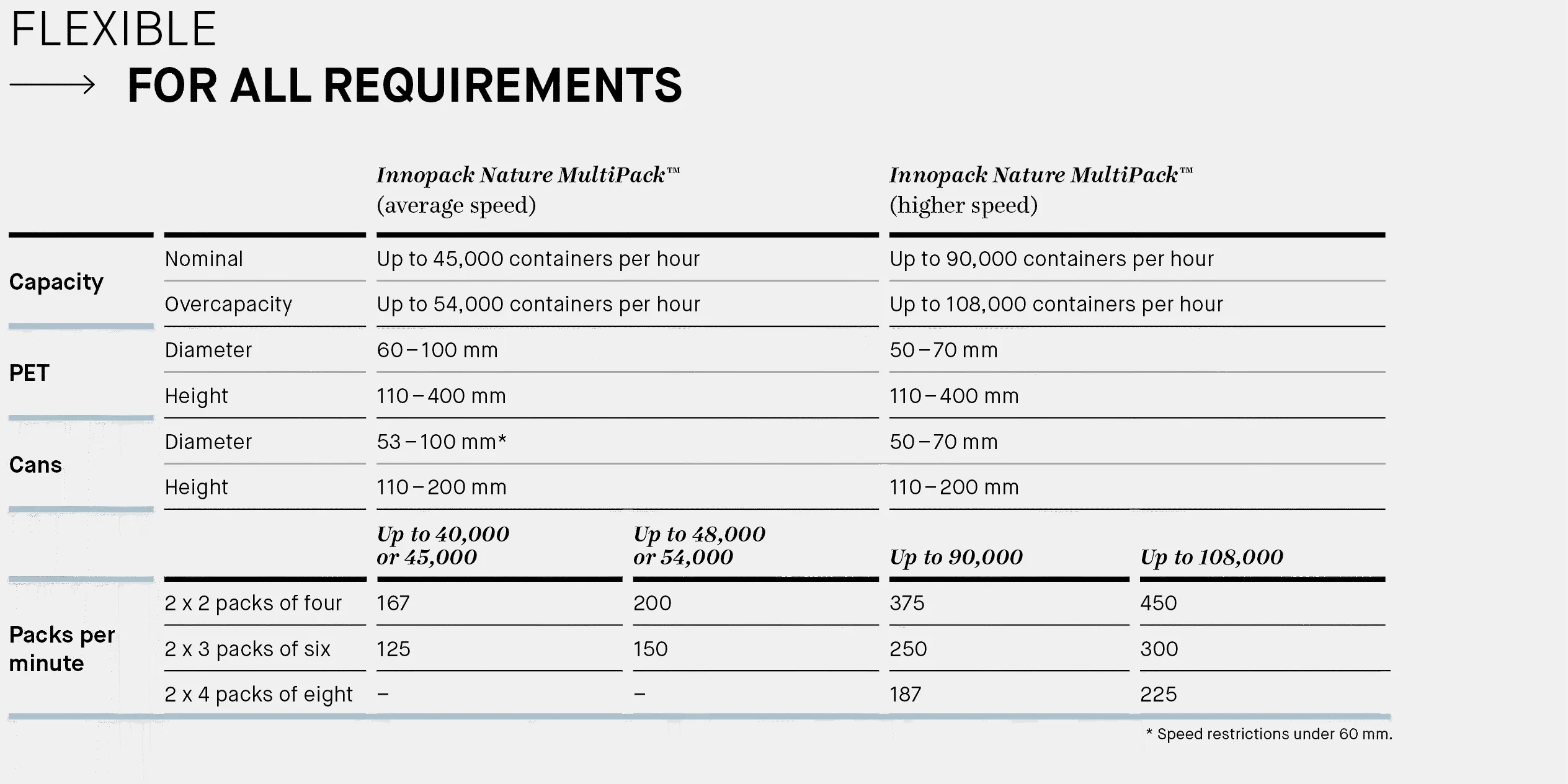

Originally developed by KHS for packs of PET bottles, the Innopack Nature MultiPack™ packaging machine was initially designed for a capacity range of up to 45,000 bottles per hour plus 20% overcapacity. It quickly became clear, however, that the sustainable concept of holding beverage containers together with dots of adhesive instead of shrink film to form a pack that’s easy to transport and easy for consumers to ‘open’ was also of interest to the canning segment. In close cooperation with the Carlsberg Group, the system has now been successfully introduced in several European countries as packs of four, six and eight cans under the name of ‘snap pack’. Choosing the right adhesive especially presented KHS with something of a challenge: numerous tests had to be run to check which specific adhesive forms a bond with the different coatings can manufacturers use on their containers.

High performance needed

However, the machine speed ultimately proved to be the greater challenge. As cans are usually filled in the high-performance range at a rate of over 100,000 containers per hour, the capacity of the machine to date was too low. Placing two machines on a line was only a temporary solution: firstly, because the footprint was then twice the size (one machine is almost 25 meters long) and secondly, because this doubled the cost of investment. Christoph Georg von Aichinger, global product account manager for NMP, stresses how important it is to not only take the CAPEX* but also the OPEX** or day-to-day operating costs into account during the decision-making process. According to in-house calculations, Nature MultiPack™ scores on the latter at €20 to €25 per 1,000 packs as opposed to cardboard carriers that cost approximately €50 for the same number of packs. “The higher cost of investment then of course pays off over a certain period,” explains von Aichinger. “At full capacity the system can even pay for itself in the first year.”

* CAPEX = capital expenditure (cost of investment).

** OPEX = operational expenditure (cost of day-to-day operation).

One important aspect for sales especially is that the innovative Nature MultiPack™ packaging concept touches on many areas of a beverage bottling plant: from purchasing through production to sales and marketing. It’s crucial to convince all of them – and especially the last two – of the benefits of this system. “The big players have a strategic agenda with which they generally pursue three goals,” von Aichinger tells us. “First comes sustainability, this achieved by saving on energy and water consumption and reducing the carbon footprint; second is the desire for growth; and third is the need to generate as high a margin as possible. Nature MultiPack™ is a system that serves all of these three purposes.” Von Aichinger knows that innovations of this kind hold increasing appeal for medium-sized, owner-managed companies, too. “Their flat hierarchies allow them to be more flexible in their decision-making. We saw this recently with the Martens brewery in Belgium, for instance. We basically agreed on a deal after just a few meetings,” the KHS salesman smiles (also see the article on ‘The beer of the future since 1758’).

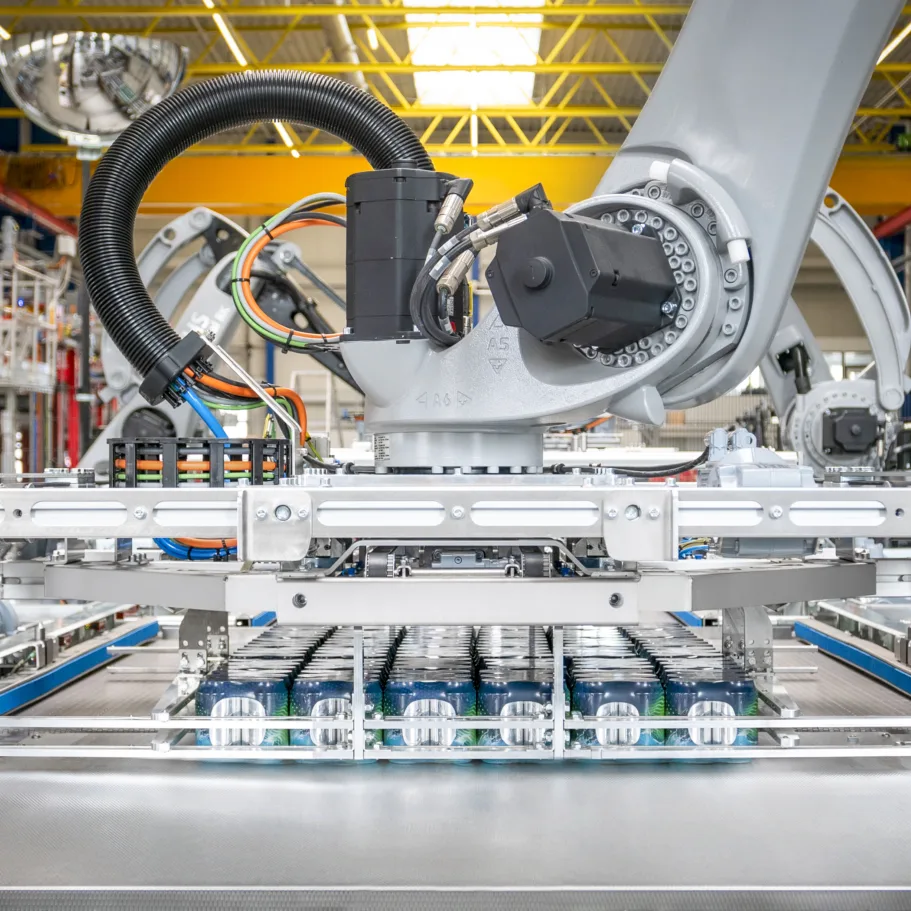

In the packaging machine’s orientation module the beverage cans are aligned in a matter of milliseconds so that the containers in the pack form a single image.

Series of innovations

What’s helpful when marketing the new technology is that KHS now also offers a further development of the existing system: Innopack Nature MultiPack™ for the high-capacity range. Running at overcapacity, it can process up to 108,000 containers per hour, with a maximum of 90,000 containers produced every 60 minutes at nominal capacity. Depending on the format, the machine can output up to 450 packs of four a minute. This boost in performance has been made possible by a whole series of technical innovations explained in detail by Dr. Matthias Caninenberg, head of Nature MultiPack™ Technology at KHS in Kleve. “The list of innovations starts with the conveying speed which we’ve increased from 51 to 72 meters per minute compared to the machine’s predecessor. So that we didn’t have to double the speed – which would have incurred a considerable amount of extra effort – the pitch was decreased on the unscrambler module. This means that the distance between the containers was reduced from 114.3 to 90 millimeters and even down to 80 millimeters following the gluing process. This allows more units to run through the machine and we get the performance we want.”

»Our innovations start with the conveying speed which we’ve increased from 51 to 72 meters per minute.«

Head of Nature MultiPack Technology, KHS

Alignment in milliseconds

In the orientation module the entire carousel has been revamped: instead of four this now has six drives that no longer rotate four but three plates apiece. This change allows time for alignment of the containers. Here, a camera takes 400 images of a container on the first reference run while it is turned 360° about its longitudinal axis. In production the container is photographed just once. With the help of a fast algorithm, this single image is compared to the 400 taken before and the current position of each single can or PET bottle is thus determined. This is then used to calculate any necessary correction to the container’s position, performed by the activated motor in a matter of milliseconds until the container is aligned as required. This is important with regard to the point of sale (POS) if the containers are to be arranged in the pack to form a single image.

In the orientation module the entire carousel has been revamped: instead of four this now has six drives that no longer rotate four but three plates apiece. This change allows time for alignment of the containers. Here, a camera takes 400 images of a container on the first reference run while it is turned 360° about its longitudinal axis. In production the container is photographed just once. With the help of a fast algorithm, this single image is compared to the 400 taken before and the current position of each single can or PET bottle is thus determined. This is then used to calculate any necessary correction to the container’s position, performed by the activated motor in a matter of milliseconds until the container is aligned as required. This is important with regard to the point of sale (POS) if the containers are to be arranged in the pack to form a single image.

Once the dots of adhesive have been applied, the containers are passed on to the compression module. “This is where the packs are formed by the containers being pressed against one another. This takes less than a second as long as the adhesive is soft,” explains Dr. Caninenberg. This aspect of the further development of the machine for the high-capacity range took up the most time and energy to bring the output up to a maximum of 90,000 or 108,000 bottles or cans an hour. In order to so do, transfer stars with fingers were dispensed with and the conveyor system was converted from chains to toothed belts. The new modular design enables the curing segment to be halved and the entire machine to be shortened by three-and-a-half meters. The effort was well worth it – and not just for the size, Dr. Caninenberg believes. “The packs are joined more gently and flexibly and the transfer process is subject to lower tolerances.”

KHS handle applicator

After compression any packs where a dot of adhesive is missing or incorrectly applied are channeled out. “The rate here is so low that it’s hardly worth mentioning,” emphasizes Dr. Caninenberg. This can be further improved by an optional air drying module that makes sure that there’s no more condensation or condensation water in the machine – an important factor when it comes to the quality of the gluing process. Another special feature awaits the packs in the handle applicator module once they’ve been split into three lanes and turned by 90°. “Here, we’re using a model developed by KHS for the first time that manages up to 150 packs a minute. As there are three applicators installed next to one another, the output amounts to 450 packs per minute; with packs of four, that’s a maximum of 108,000 containers that can be processed every hour.” Alternatively, 300 packs of six or 225 packs of eight containers a minute can also be produced on the new machinery.

The focus is on flexibility – also with respect to the footprint of the packaging machine. “If there are problems with the length of the machine, the layout can also be angled 90 or 180° in the middle,” states Dr. Caninenberg. This means that the further developed Nature MultiPack™ system for the high-performance range can also be adapted to suit more complex space requirements.