Convertible

Little effort, big impact: this is what you get with the new quick neck change option on the InnoPET Blomax when manufacturing PET bottles. It considerably reduces the time needed for changeovers, giving bottlers greater flexibility and higher efficiency in production.

Whereas in the past only one category of product was usually run on aseptic lines, bottlers of sensitive beverages now face an ever-growing demand for flexibility. Beverage producers who process both aseptically filled beverages and juice and carbonated soft drinks need to use 38-millimeter bottle necks for the former and containers with 28-millimeter openings for the latter. If the bottle neck is to be changed on a PET line, however, to date a comparatively large amount of effort was required to convert the stretch blow molder in particular, meaning that the machines often clocked up over four hours of downtime – tying up the often very few operators of the same for a disproportionately long period of time. It’s thus common to try to only manufacture and fill bottles that have an identical neck on one line.

If a water bottler wants to produce a still and a carbonated product alternately, until now it had to decide whether to use the higher and heavier neck really only necessary for carbonated water for both products or not. The bottler would then save time but waste material and money in the filling of the still water. The alternative would be to live with the long intermittent downtimes caused by a neck changeover. Besides these considerations, marketing often plays a role in a decision like this, calling for a bottle adapted to suit the various products. Combined lines such as these that require neck changes are very often found in Japan.

Complex process made simple

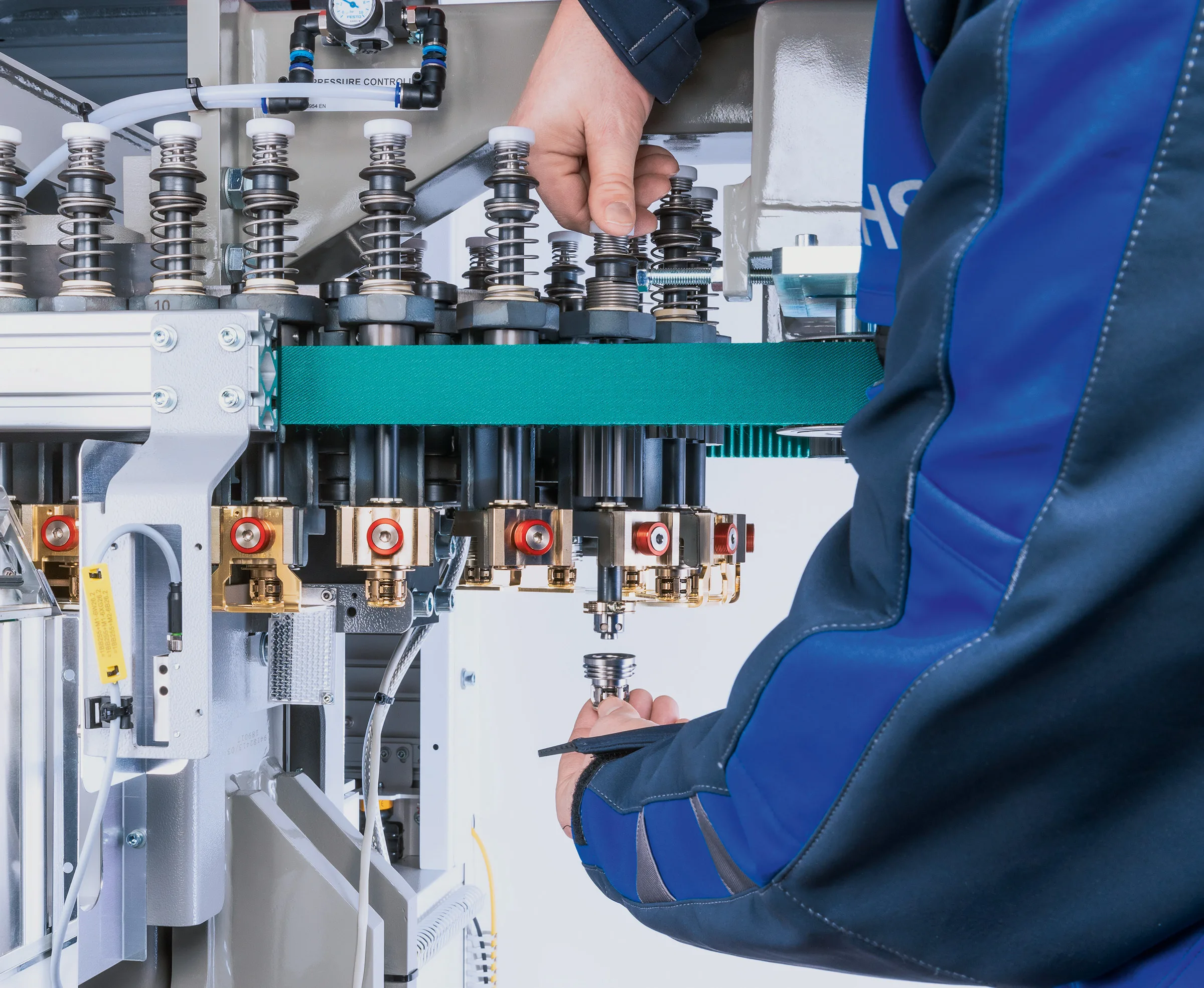

In order to gain an idea of just how complex the exchange of parts for the above process is on the stretch blow molder alone, it’s worth taking a closer look at the individual steps involved. First, the preform infeed needs to be adjusted and what are known as the mandrel heads replaced that are wedged into the preform necks to guide these safely through the heating module. The grippers that transport the preforms by their necks to the blow wheel are then exchanged on the star wheel. Finally, the molds in the blow stations, the blow nozzles and often the stretch rods and further grippers downstream that feed the finished containers to the subsequent filler have to be changed over. Here, the number of parts that need replacing depends on the size of the machine. The mandrels and shields especially are of particular importance: the higher the machine output, the longer the heater, as the containers may move faster but always require the same amount of time to heat up. On an InnoPET Blomax 16 stretch blow molder with a capacity of up to 48,000 bottles per hour, around 170 mandrel heads and shields have to be changed by hand, for instance. This means that this part of the neck change is particularly relevant when it comes to the amount of time needed – unlike the exchange of the just 20 grippers that’s quick in comparison.

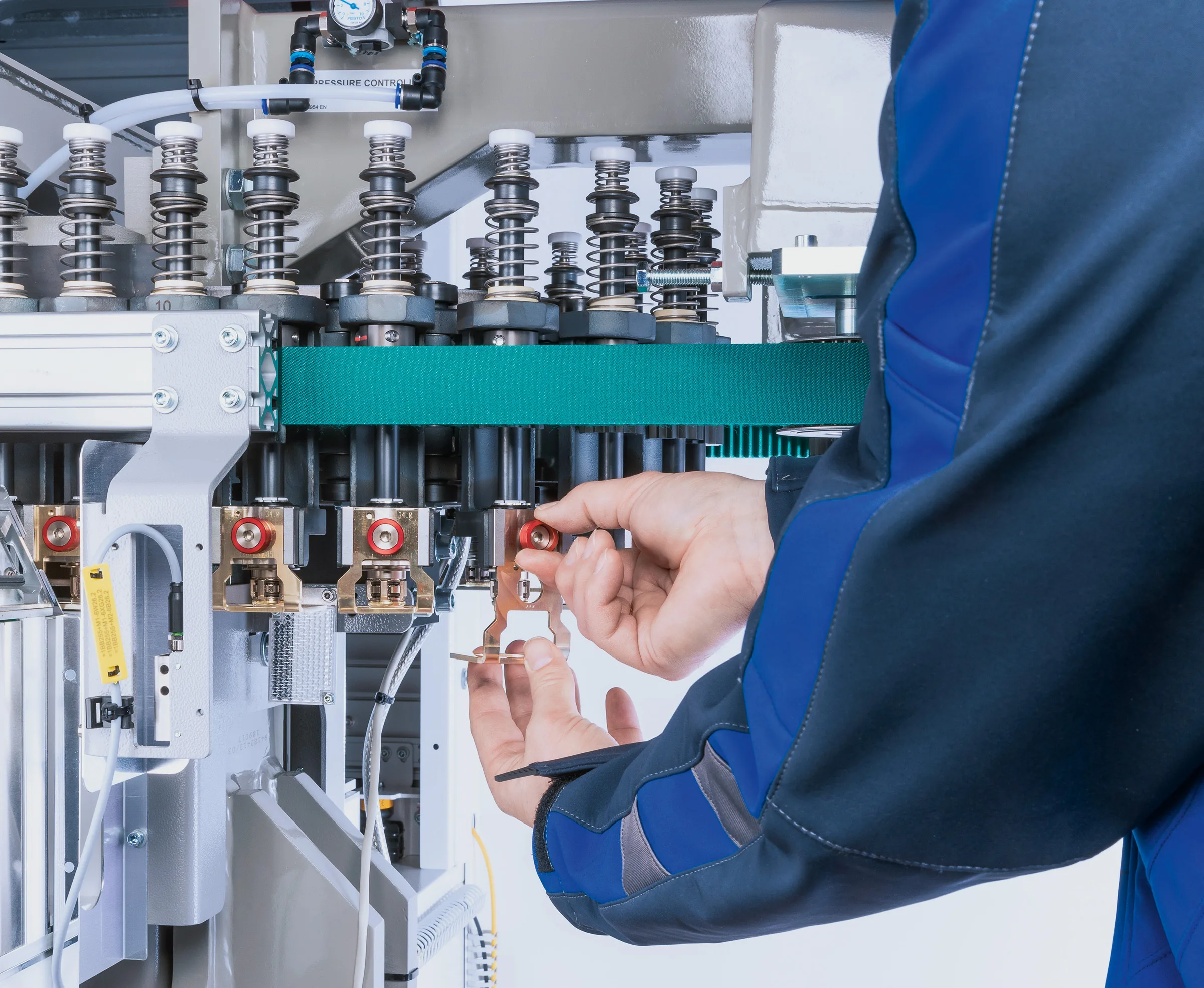

Step 2: The mandrel head is then released by simply pressing on a spring, enabling it to be changed over quickly and easily.

Step 1: When converting the stretch blow molder to a different neck, the shields are first exchanged.

In order to considerably speed up the conversion process as a whole, KHS hasn’t just simplified the individual work steps involved but also the concept governing the entire procedure. “We started out by analyzing how the operators work,” says Arne Andersen, stretch blow molding product manager. “On this basis we then considered how all tasks could be made easier and organized as perfectly as possible – paying particular attention to the ergonomics. Magazines were thus installed that stop the operator having to repeatedly abandon the machine to fetch and carry change parts, for example. We also replaced the grippers to reduce the number of screws that need to be loosened. At the same time, newly developed mandrel heads are now used that can be simply removed by pressing a release spring. This process used to be much more complex.”

»The much shorter conversion time for neck change-overs gives our customers totally new options in their production planning.«

Stretch blow molding product manager, KHS

Thought through to the end

In this case, KHS consciously went for an approach that thought all of the specific processes through to the end based on actual customer requirements, Andersen emphasizes. “We aimed to achieve the best possible improvement within the shortest possible time.” KHS managed both: thanks to the simple neck change, the time needed for two operators to convert the Blomax 16 stretch blow molder, for instance, has now been cut by a good two thirds to approximately just 86 minutes – including the preform infeed.

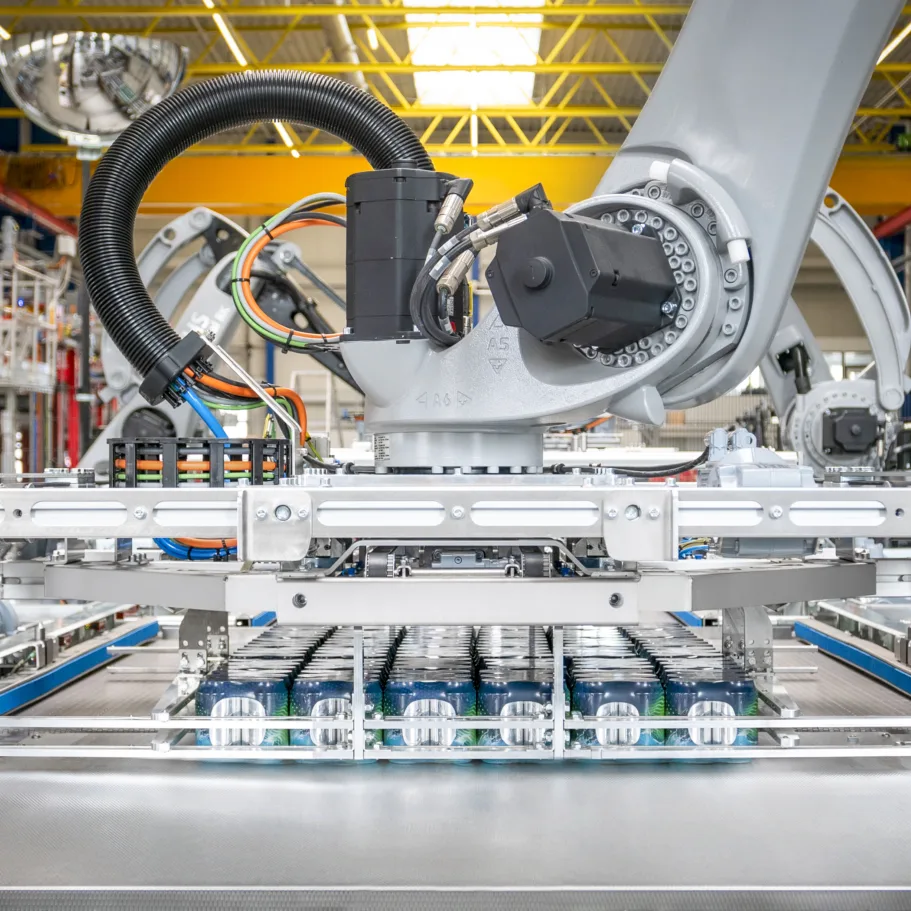

As the PET bottles in a block like the KHS InnoPET BloFill are held and conveyed by their necks throughout the entire machine, not only the stretch blow molder but also the filler has been developed further in order to shorten conversion times. The capper was one particular area of focus, where the cone responsible for lifting and closing the bottles needs to be replaced manually. No conversion is required regarding the screw cap, however, as there are two cap feeds – one for each neck diameter in the respective format.

Andersen is convinced that the new neck change option will give beverage producers much greater flexibility, as they can now also run much shorter production cycles for bottles with different necks and therefore reduce their warehousing effort accordingly. “Some of our customers produce just in time; this means that the finished containers are loaded straight onto the truck without any interim storage. The drastically reduced conversion time will now enable filling operations like these to change necks more frequently; they thus profit from totally new options in their production planning.” The same goes for converters who can now produce the generally smaller batches for their customers – often in very different bottles – on a single line much more efficiently.

The first customers in Asia who are already using the quick neck change developed by KHS are extremely pleased with the amount of time and effort they save. This retrofittable option has thus earned plenty of praise from KHS’ clients in this region.