Technology for tomorrow

Industry pioneers such as Lorenz Adalbert Enzinger and Theo Seitz bear witness to the long tradition research and development enjoys at KHS. Like them today’s KHS engineers don’t always go with the flow but pursue many different paths in order to stay at the helm of progress.

For several years now a new acronym has been repeatedly bandied by economists and politicians: VUCA*. It defines a world which is being increasingly characterized by volatility, uncertainty, complexity and ambiguity. Rapid fluctuation and high risk create challenging conditions for strategic corporate management – and for further technological development in industry. This naturally also applies to mechanical engineering and to KHS in particular, as the beverage industry, to which the Dortmund company is one of the leading systems suppliers, is subject to extremely dynamic cycles of change.

In order to survive in this VUCA world and prepare for the future, a certain agility of thought and action is required. For KHS, for instance, this means focusing on the relevant issues in research and development. While a manufacturer presents its customers with something new on its own initiative in what’s known as a technology push, a market pull primarily denotes an action triggered by the sales market.

* VUCA = volatility, uncertainty, complexity and ambiguity.

KHS 4.0

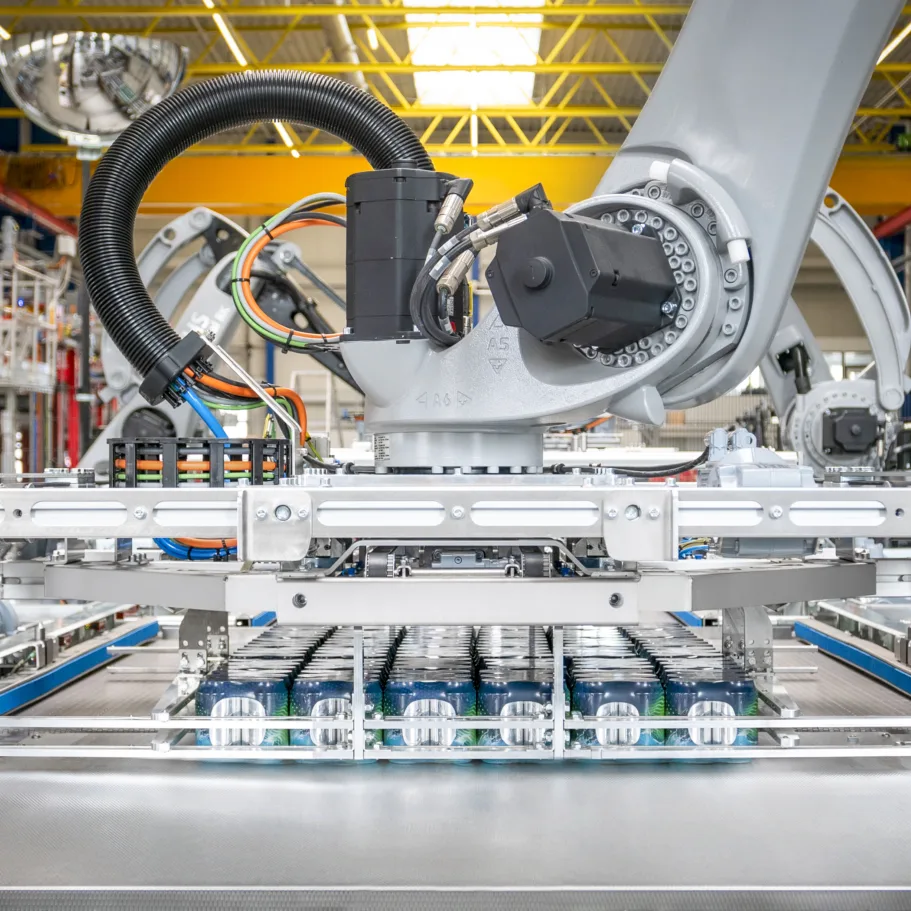

At present and in the future the focus of digital development at KHS will be on lines and line optimization as the following examples illustrate:

3D line design

With 3D line design entire lines can already be visualized virtually at the offer and planning stage. Customers can ‘walk’ through the line and the design can be finalized early on in the design process. This helps to prevent later changes having to be made which always bear a certain processing risk and can have a negative effect on the success of the product in terms of both time and money.

Production management system

An extended production management system, which includes functions such as material reconciliation and bills of materials, enables much faster format and product changeovers without loss of materials or product and thus gives operators greater flexibility.

Hardware and software simulation

Hardware and software simulation permits the virtual commissioning of machines. This shortens lead times and improves quality. In the medium term a digital twin will evolve from this which will also benefit service and maintenance.

Further developed ClearLine HMI

The further developed ClearLine HMI with gesture control and a larger display makes system operation more intuitive and work easier.

Focus on requirements

Within its company strategy KHS has decided to focus on the fast-changing requirements of beverage producers. At the moment considerable effort is being invested in aligning the portfolio more specifically to target markets with a strong potential, for example. More than ever before the company has its ear to the market and aims to exploit the proximity of its sales and service organization to its customers. In order to successfully learn with and from its customers, established, trusting business relations are called for which KHS enjoys with many partners worldwide. Only within these is it possible to brave new technologies with realistic expectations and without bias as to the results. This includes openly discussing both problems and progress in a kind of ‘protected environment’ in order to be successful together – but also that those involved recognize when it no longer makes any sense to continue with a project.

Joint development

The partnership with the French food group Danone is a good example of this type of cooperation. This has resulted in the film-free Nature MultiPack™, first presented as a concept at drinktec in 2013, was readied for serial production and then launched to market with the Evian mineral water brand. The same technological principle was adapted together with Carlsberg for the beverage can and exhibited at drinktec in 2017.

With its new, even more user-friendly mode of machine operation the further developed ClearLine HMI from KHS meets the greater demands being made in the world of work.

New projects have to satisfy two requirements: the concept of effectiveness dictates that the right things are done, that is that the correct emphases are placed so as to come as close as possible to the market and yield the greatest possible benefits for the customer. The second requirement of efficiency demands that things are done correctly, in other words that maximum productivity is assured in the product development process from the initial idea to the rollout. This doesn’t prove successful when innovation is merely treated from a technological point of view. Greater priority is to be given to customer benefits through even closer dovetailing of and constant coordination between the Design Engineering, Production and Sales departments. More intensive communication between customers, KHS Sales and KHS Technology is to ensure that specifications can be better recorded and more directly implemented in the various system solutions.

Five questions for Dr. Ing. Matthias Schopp

How must KHS develop to also be successful on the market of the future?

As part of the mission statement process managed by our parent company Salzgitter we’ve made customer orientation the value of the year. We’ve received constructive feedback from many of our customers all over the world. On this basis we at KHS will focus on effecting even better cooperation across our divisions and departments in the future. In doing so we’ll make a further move towards the customer – and not just from a sales point of view. After all, every single action counts within a company – regardless of in which department.

What’s your position on digitization as one of the people responsible for research and development at KHS?

In its implementation digitization is more of an evolution than a revolution. Much of this has been going on for years: new functions in individual assemblies are successively changing lines and machines; components are becoming more intelligent and expanding the possibilities of superordinate control systems; networking is creating added value, such as in process monitoring or machine diagnosis. We’re integrating these and many other aspects to form a turnkey system. In doing so we ask ourselves two questions: what’s the relevant added value for our customers? And what’s the relevant business model for us?

In which direction do you think Industry 4.0 will develop?

Industry 4.0 will create greater transparency in processes and in doing so make the operation of a line much more efficient. We can already see some of its manifestations: the evaluation of sensor data collected along a line, for example, allows local and superordinate functions to be improved. Other characteristics will ensue – such as for self-optimizing lines.

How will this work in practice?

In the DnSPro* research project we measure the foaming on filling machines with the help of cameras. The idea behind this is that in the future the machine can optimize itself to suit a new product as the automated variation of the filling parameters replaces the manual adjustment process. Applications like these won’t be available in the near future, however.

* DnSPro = sensor-based subsystems with decentralized cooperation for Industry 4.0 production systems, sponsored by the German Federal Ministry of Education and Research (BMBF).

Don’t developments like these make machine operators redundant?

No. Our aim must be to make human operation of the increasingly complex technology demanded by the market easier. With the help of artificial intelligence we want to make self-learning and self-optimizing systems feasible which with their great flexibility can be managed by humans and thus enable highly efficient, cost-effective operation. This isn’t just our vision but that of the entire industry, also of our partners.

One central idea for the future is to lower the overall operating costs by reducing materials, for instance. Lightweighting can help to cut costs here.

To KHS networking and cooperation with external partners are of great importance as major drivers of progress. Not only customers but also suppliers are included here – for example those who provide measurement technology, components or software – as well as research institutes and universities. Two of the research projects KHS is currently involved in are dedicated to the application of new manufacturing technologies. One disruptive approach is the 3D printing of parts which can barely be produced cost effectively in the classic manner or whose geometric shapes are far superior to the doubles produced conventionally, for instance.

Digital pioneer

KHS takes a clear stance on the hype surrounding digitization which is often quoted when talking about the future viability of the industry: beyond the buzzwords and a number of interesting trends the sole criterion for the implementation of ideas based on digital technologies is the added value for the customer. Incidentally, KHS has every right to be confident here as it is a pioneer in many fields – such as in 3D line design which the company has been practicing for over ten years.

In addition to its digital projects KHS is concentrating on two more future issues. One of them isn’t new: this is the total cost of ownership (TCO) factor, including all measures which enable the beverage industry to keep its overall operating costs down to the absolute minimum. It covers aspects such as lightweighting, i.e. reducing the weight of PET bottles, material, media and energy consumption, an increase in productivity and simpler operation.

Simulation using digital twin and augmented reality can also be extremely helpful for service and maintenance.

Efficient configurations

The other topic for the future which KHS has been committed to for a long time now encompasses modularity and standardization. Here, the aim is to provide as much variety as possible externally while producing with the lowest possible variance in house. A limited number of modules with tried-and-tested functions forms the basis for this, with which the maximum possible number of configurations can be efficiently made. A system such as this permits lower lead times in production and faster commissioning. This approach is already being adopted in the field of aseptics, for instance. The result is a configured system with a manageable risk and a very high quality – and this is a foundation customers can build on.