Make three wishes

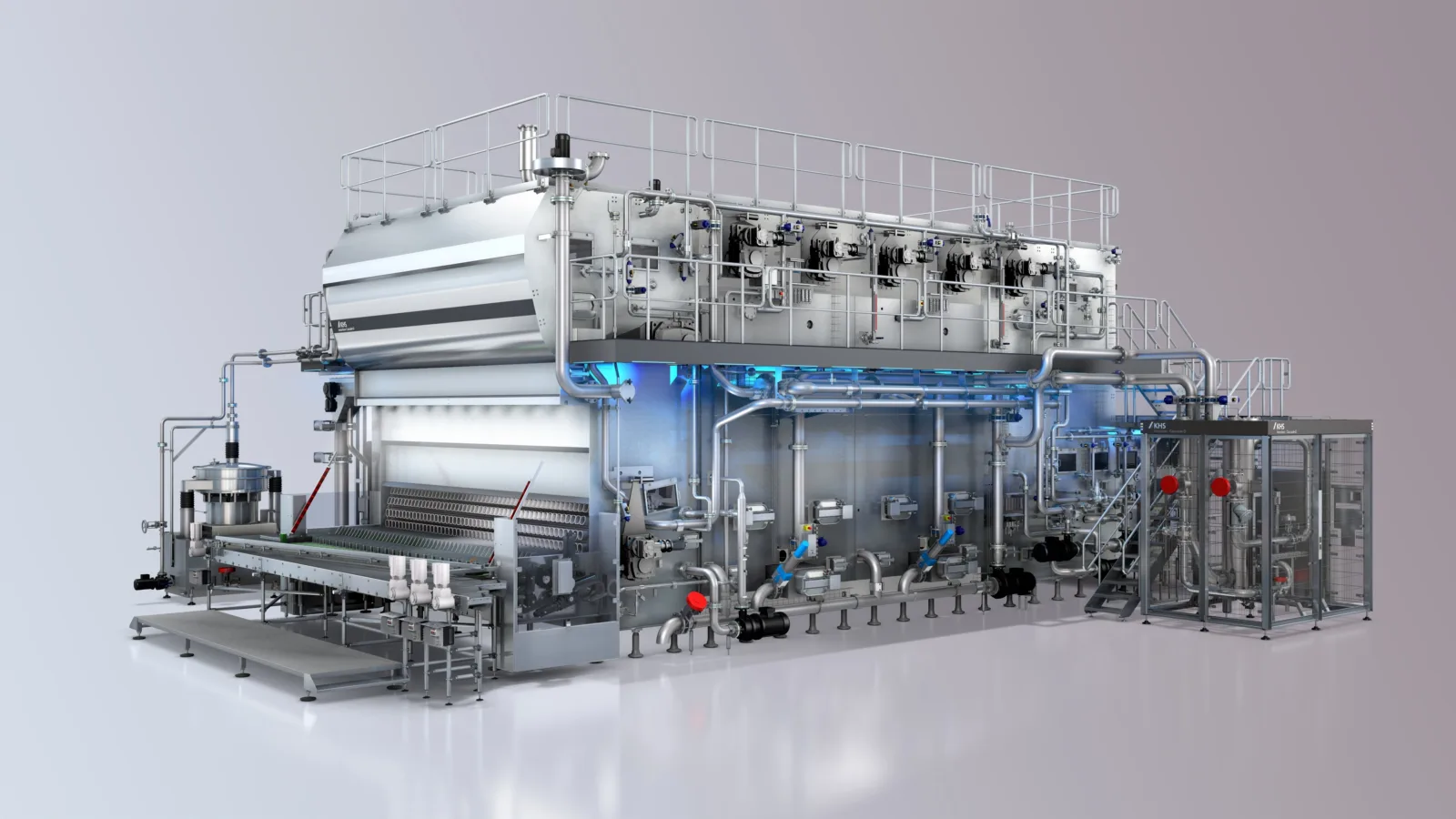

Regarding resource conservation, space savings and ease of maintenance, the Innoclean Cascade D is setting new standards in bottle washing. At drinktec, KHS will be presenting three examples from a considerable number of improvements.

Dortmund systems supplier KHS is getting ready to launch a new generation of double-end bottle washing machines. In doing so, it’s catering for the most pressing requirements of the beverage industry. First and foremost of these is the total cost of ownership or TCO, an observation of the total operating costs. The Innoclean Cascade D primarily scores here with its much lower energy, media and water consumption.

The second key criterion is the physical footprint of this large-volume system. “By making the new machine 50 centimeters taller than its predecessor, we can cut the amount of space needed by about 10%,” explains Knut Soltau, product manager for bottle washers and pasteurizers at KHS. “This means that the same caustic submersion time can be implemented in a smaller base area.”

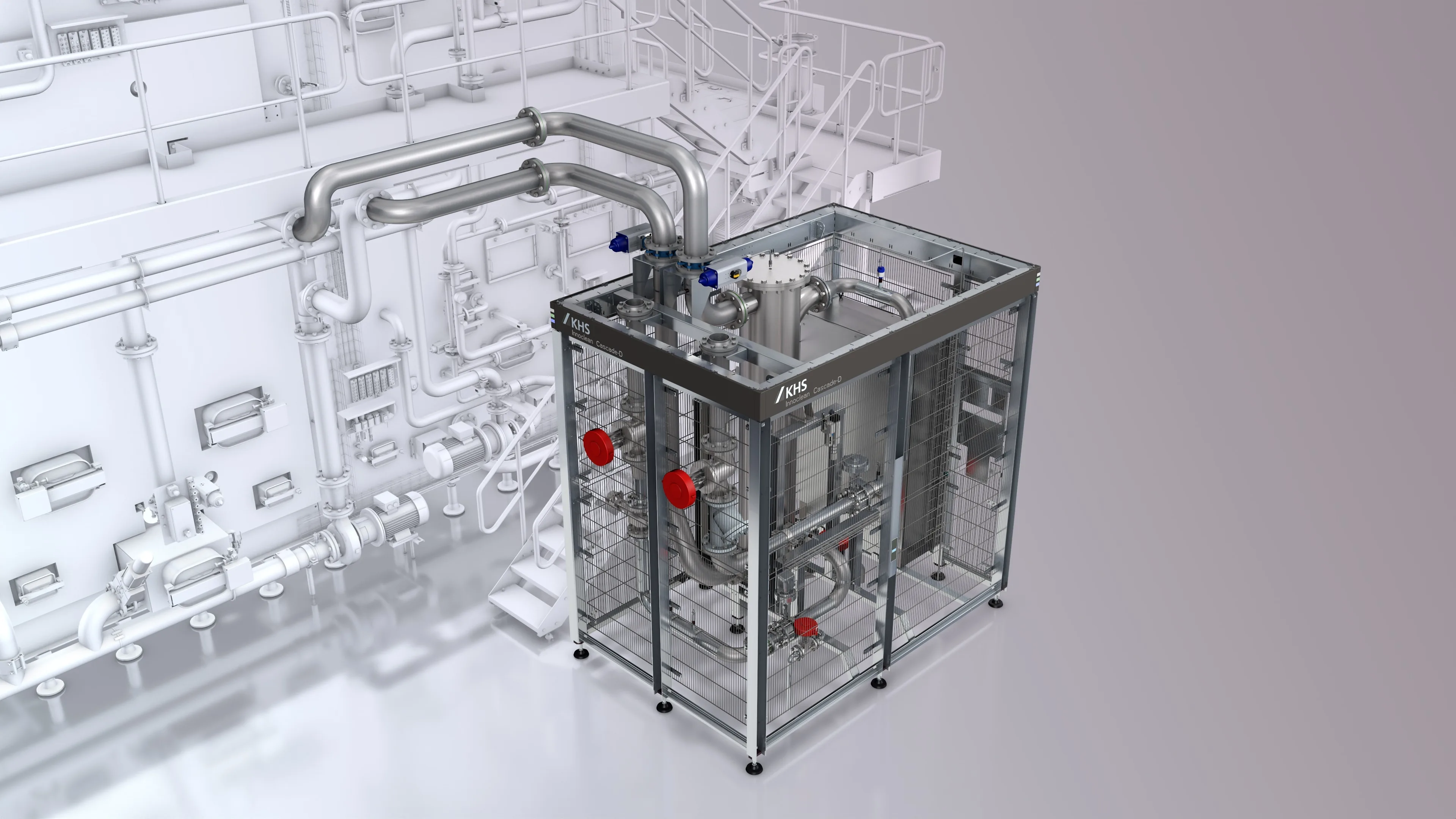

The heating system has been extracted from the machine body and positioned beside it - with a perfectly reachable upright heat exchanger that is easier to maintain and clean.

Finally, the third aspect concerns the overall equipment effectiveness (OEE): with respect to availability, performance and quality, the Innoclean Cascade D is convincing with its high process reliability and optimum accessibility, making both maintenance and servicing much simpler. “One example of this are the heat exchangers used for heating that used to be housed at the top of the machine in the caustic bath across a length of several meters,” Soltau says. “We’ve now extracted this function from the machine body and positioned it in a small area next to the machine where it’s perfectly reachable – with an upright heat exchanger that's much easier to maintain and clean.” Another example is the orderly side wall of the machine with its clearly structured piping array and perfectly placed, readily accessible components.

“Our new machine concept caters for the requirements of the beverage industry: TCO, machine footprint and OEE.”

Bottle washer and pasteurizer product manager, KHS

During drinktec, at its booth KHS will again be giving a sneak preview of three exemplary technical highlights from this new machine generation:

Highlight 1

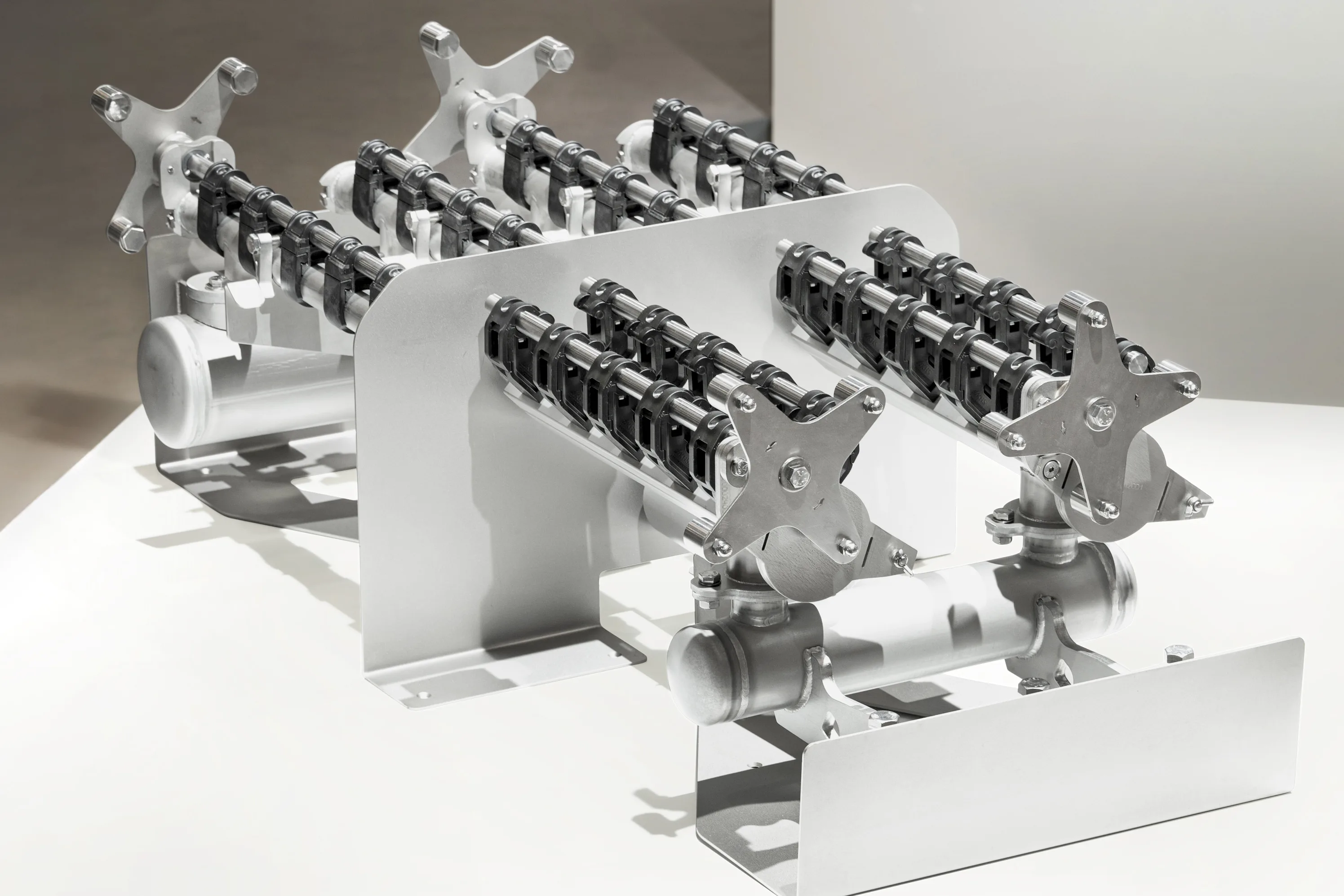

ECO carrier 2.0

A further new feature is the ECO carrier 2.0 bottle pocket that now weighs less in total than before thanks to larger cutouts on the sides. This reduces both heat and liquid carryover. Both together make for huge savings in water. In addition, the optimized geometry of the bottle pocket carrier ensures a more targeted flow through the pockets and thus improves label discharge.

Highlight 2

New chain wheel

“Even if chain wheels don’t need to be serviced very often, to date this was an elaborate process,” Soltau continues. “They weigh over 80 kilograms and to replace them, all of the drives had to be removed and the shafts lifted out of the machine at a working height of up to five meters with the help of a crane.” On the Innoclean Cascade D, the wear section is replaced by changing subsegments of the chain wheels that at just 13 kilograms clock up about 84% less on the scales.

The ECO carrier 2.0 bottle pocket scores with lower weight, huge savings in water and improved label discharge.

Instead of replacing the heavy chain wheels entirely, only significantly lighter subsegments of the wear section must be changed.

Highlight 3

New spraying system

The newly designed spraying system is much more compact and easier to service than it used to be. Soltau describes its task and function. “Sprays are used during pre-washing and pre-heating at the beginning and – more importantly – end of the machine, where they rinse the bottle interior clear and cool the bottle body back down.” What are the specific improvements here? “Instead of two spray pipes, each module now only needs one,” states Soltau. “And if we take a look at maintenance, our customers benefit here, too, as the new system has fewer parts that can be easily pulled out of the side of the machine.”

The new spraying system on the Innoclean Cascade D (in the foreground) only needs one spray pipe and can be easily pulled out of the side of the machine for maintenance purposes.

According to Soltau, beverage producers won’t have to wait much longer for this new benchmark in TCO, machine footprint and OEE: the first new-generation KHS bottle washers will probably be available on the market from the middle of 2026.