Connect four

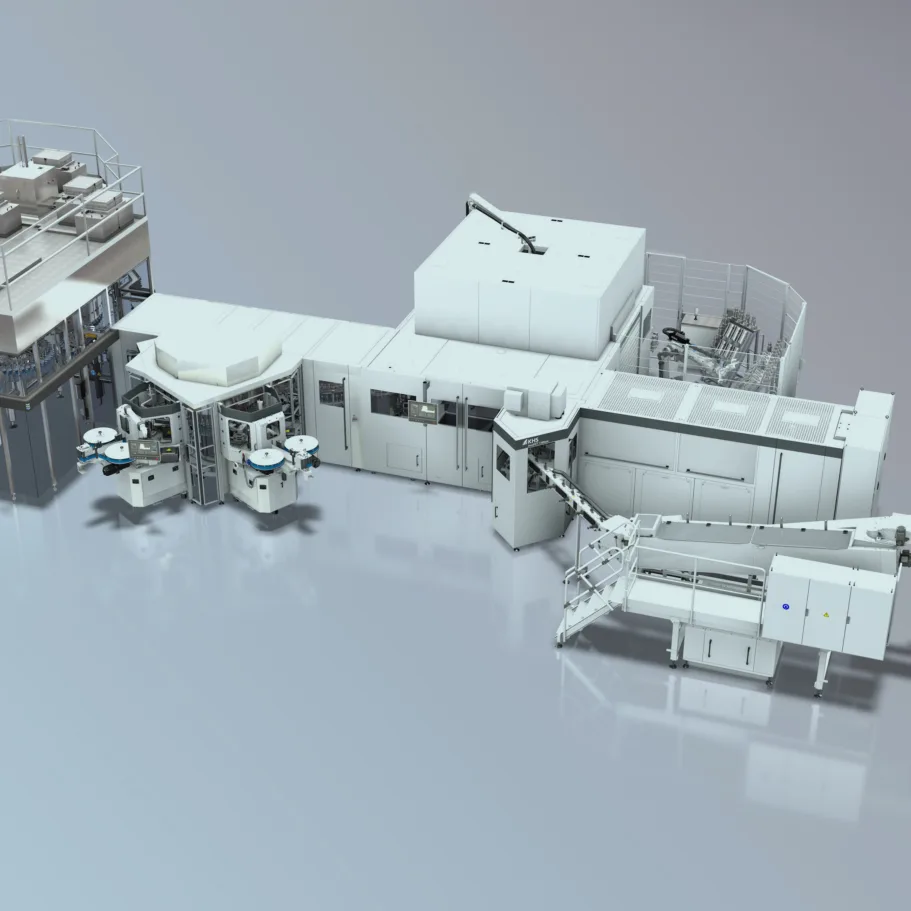

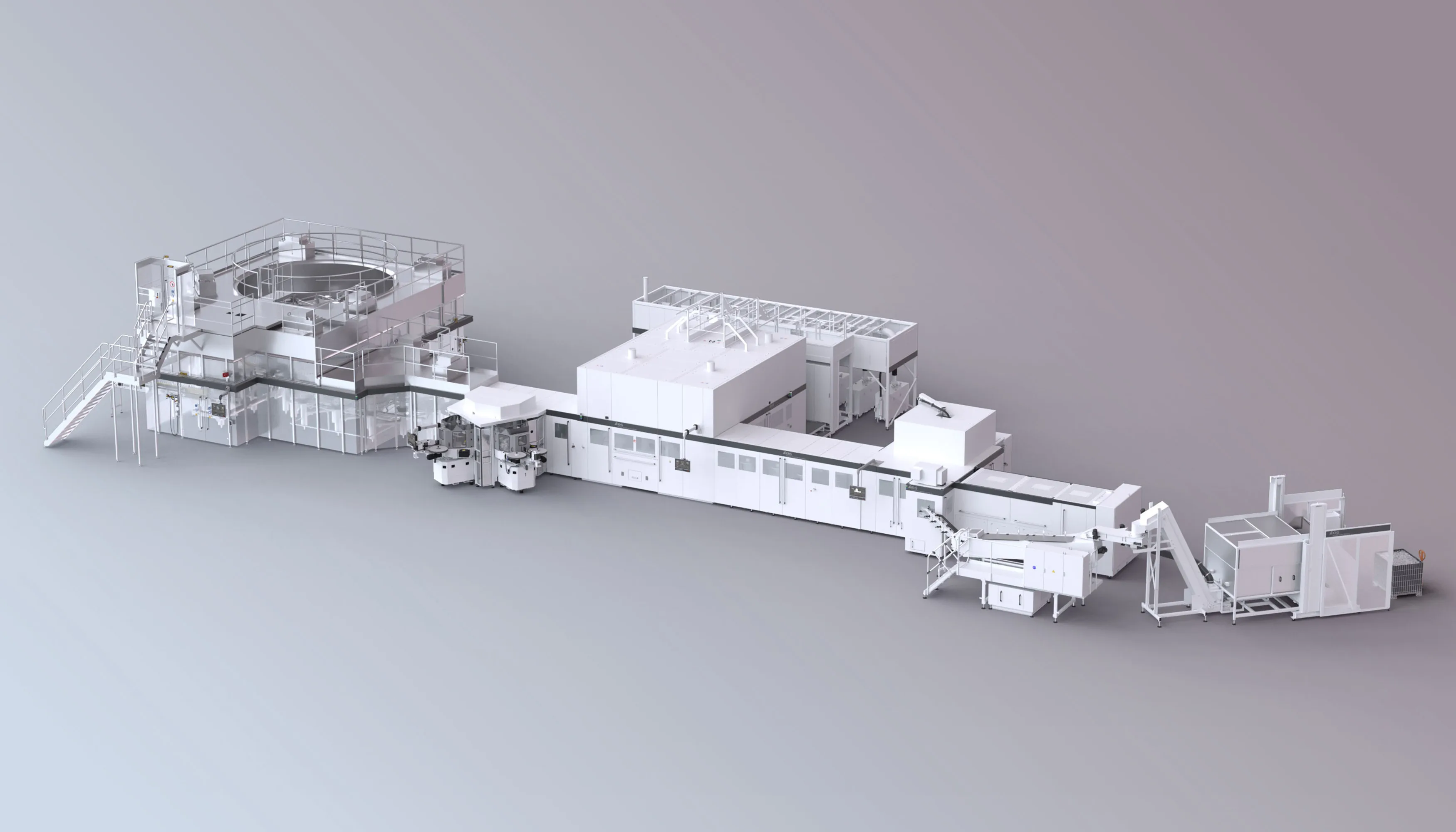

The new KHS InnoPET FreshSafe QuadBlock system combines stretch blow molding technology, labeling and filling with InnoPET Plasmax barrier technology for the first time – a groundbreaking innovation in PET bottle production.

Stretch blowing, filling and labeling – these core processes in PET bottle manufacturing all run with maximum line efficiency on the tried-and-tested InnoPET TriBlock from KHS. As a consistent further development of the TriBlock and worldwide product innovation, the Dortmund systems supplier now presents the InnoPET FreshSafe QuadBlock. The block system makes it possible to produce PET bottles complete with integrated barrier protection, effectively protecting the bottled products and enabling them to keep for considerably longer.

“For us, the FreshSafe QuadBlock is the next logical step in machine blocking,” says Dr. Joachim Konrad, head of the Large Machine Product Division at KHS. “By further developing our existing blocks for PET bottle manufacture and filling, we’re not only boosting our customers’ line efficiency but also helping them in their efforts for more sustainability.”

“For us, the FreshSafe QuadBlock is the next logical step in machine blocking.”

Head of the Large Machine Product Division at KHS

Stable, lightweight, longer shelf life

The FreshSafe QuadBlock efficiently produces and fills PET bottles of different shapes and sizes. And what they all have in common is the lowest possible weight coupled with optimum stability. In this way, customers save on packaging material without having to compromise on product safety.

This is facilitated by the integrated InnoPET Plasmax barrier technology from KHS. This process applies a wafer-thin, glass-like coating to the inner wall of the PET bottle, effectively protecting sensitive product from carbon dioxide loss and oxygen pickup. “The FreshSafe QuadBlock thus unfolds its full potential with carbonated beverages in particular. The products have a shelf life that is two to six times longer,” explains Philipp Langhammer, product manager for barrier technology at KHS. Another key advantage of barrier technology is that, when the coated bottles are returned to the recycling loop, they are just as fully recyclable as containers made of pure PET.

“The FreshSafe QuadBlock scores with carbonated beverages in particular. The products have a shelf life that is two to six times times longer, require less packaging material and are fully recyclable.”

Product manager for barrier technology at KHS

Optimized processes, greater efficiency

In addition to the integrated coating module, the new block system is convincing thanks to optimized process sequences. On the FreshSafe PET QuadBlock, the bottles are labeled after coating and before filling while dry – without disruption from cleaning water or condensation. This enables an entire blower unit for bottle drying to be dispensed with – plus the energy needed to power it. The buffer table upstream of the labeler is also no longer required, reducing the number of drives on the container conveyor by 60%. The block is thus more sustainable and has a higher availability.

The new KHS system also addresses further current and future requirements of the beverage industry. “Making use of available space is a key challenge for our customers. Block systems provide the key solution here,” says Langhammer. By blocking four machines instead of three as in the past, the FreshSafe QuadBlock takes up less valuable space. Compared to the TriBlock, container conveying has been significantly streamlined and the number of transfer points reduced thanks to end-to-end neck handling.

Flexibility and simple operation

The turnkey system is also compelling regarding its handling, for in their blocked state the modules run in unison. For beverage producers, this means simplified operation and so fewer personnel are required. Despite blocking, the modules can be serviced and activated separately from one another, so that maintenance work can be carried out in parallel.

By blocking four machines, the FreshSafe QuadBlock takes up less valuable space, while the highly streamlined container conveying segments considerably boost line availability.

Holistic line solution

KHS’ holistic line concept has also been consistently implemented on the new machine. “The FreshSafe QuadBlock produces finished PET bottles of the highest quality – coated, labeled, filled and sealed,” summarizes Konrad. “The products then only have to be packed and palletized.” A direct link to downstream packers and palletizers using a simple buffer system ensures seamless integration into the PET line. This makes the FreshSafe QuadBlock the heart of an efficient, end-to-end chain of production.