Flexible genius

KHS’ new secondary packaging machine forms beverage cans into packs without the need for any plastic or adhesive whatsoever – using a technology that leaves nothing to be desired when it comes to flexibility and modularity.

KHS has now added a completely new technology to its extensive range of machines for secondary packaging: the Innopack Kisters CNP (Carton Nature Packer) is a modular system customized to beverage producers’ exact wishes and market demands that can be added to as and when required.

“In light of the growing demand for plastic-free packaging, the beverage can is currently growing in popularity, especially in the beer and carbonated soft drink segments,” explains global packaging product account manager Sören Storbeck. “Secondary packaging is also in focus, for which suitable systems and solutions must be found that do without plastic and can be ewasily recycled.”

One said solution is the CNP. To be more precise, this is a cardboard clip or topper that bundles beverage cans together to form a stable pack with the help of ‘claws’ clipped under the upper rim of the can. As the pack is held together by the punched and folded clip alone, the CNP meets the highest demands for sustainability. Recyclable, biodegradable and recycled cardboard can be processed by this machine. The cardboard can toppers, available in a closed (TopClip) and open (GreenClip) version, are by Smurfit Kappa, one of the biggest manufacturers of cardboard in the world. The smooth surface of the first variant provides plenty of room for advertising messages, giving customers a range of branding options.

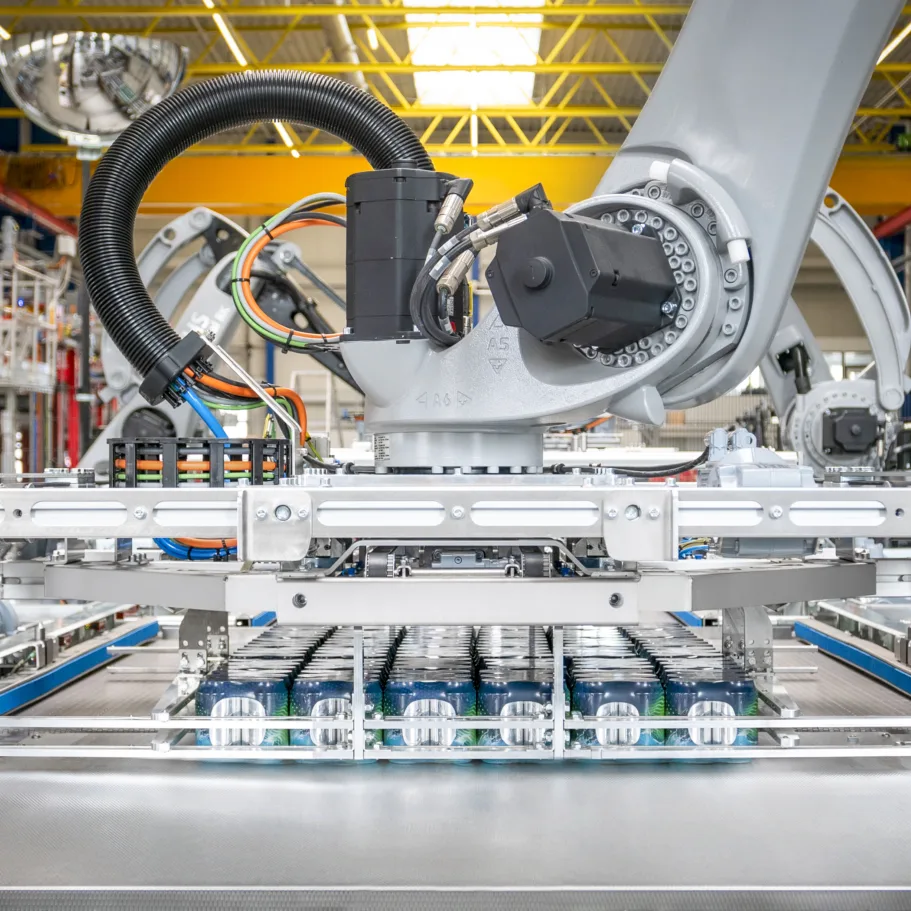

The cardboard clips or toppers are positioned on the cans before the wheel clamps their ‘claws’ under the rim of the can and erects the top.

As an option, the machine can be equipped with a camera-controlled orientation module. This enables the cans to be individually and precisely positioned within the Carton Nature Pack and made more visible to the consumer, thus heightening the product’s presence at the point of sale.

The machine has been developed by the KHS Packaging Technology Product Center in Kleve in close cooperation with Smurfit Kappa. “Our partnership was extremely helpful,” smiles Storbeck. “Being in close contact with the blanks manufacturer allowed us to make certain adjustments and react in such a way so as to optimize the packaging’s performance time and again. Extensive testing of the stability and handling of the pack also played a part here.”

»In the Carton Nature Packer we’ve found a sustainable system that does without plastic and is easily recyclable.«

Global Product Account Manager Packaging, KHS

You can find more information about our Innopack Kisters CNP packaging machine plus an illustrative video on khs.com

Great flexibility

In relation to the open topper solution, whilst still working very closely with Smurfit Kappa, KHS found it important to also find a solution that is independent of the blanks manufacturer in order to offer its customers great flexibility and freedom when choosing their packaging materials suppliers. “Although our machine also processes solid cardboard,” Storbeck continues, “corrugated cardboard will probably be first choice here for reasons of sustainability, as this has a much lower carbon footprint.” The open version of the cardboard clip is also a good alternative to the plastic rings popular in Southern Europe, for example, that have fallen into disrepute in conjunction with marine littering and have now been completely banned in Spain, for instance. Besides avoiding plastic waste, in direct contrast the new secondary packaging also scores here with its low-emission packaging process that no longer requires a shrink tunnel. This also helps to considerably reduce the carbon footprint – compared to both plastic rings and products wrapped in shrink film.

Three questions for ...

Joost Nawijn

Packaging material development specialist at Grolsch. He develops packaging that combines consumer demand for convenience and environmental friendliness with the requirement for efficient production.

1. Which former type of packaging is the Carton Nature Pack replacing at your plant?

We plan on replacing all can packs previously wrapped in shrink film with TopClip packs from the end of 2022.

2. What ultimately prompted you to go for the KHS Innopack Kisters CNP?

We opted for KHS’ new machine system for two reasons: firstly, we were convinced by the cooperative partnership between the Dortmund machine and systems manufacturer and Smurfit Kappa for the further development of the TopClip. Secondly, we can rely on our high requirements being met, namely for reliable pack processing and high-speed can alignment.

3. Which specific benefits are you hoping the new packaging system will give you?

For us, the TopClip is a strong and stable pack that can be extremely reliably produced with regard to both its quality and the processing speed. The two most important benefits in our view are that the packaging is formed without the need for any adhesive and that we can align the cans within the pack.

»With KHS we can rely on our high requirements being met.«

Packaging Material Development Specialist at Grolsch

The new Carton Nature Packer from KHS is not only flexible in its machine configuration and choice of blanks used but also regarding the can formats. “In addition to the standard 66-millimeter diameter, the system of course also processes sleek cans 56 to 58 millimeters wide holding between 250 and 580 milliliters, with volumes up to a pint or 568 milliliters for standard cans,” Storbeck tells us. “At the moment the CNP can produce packs of four, six or eight containers.” The various different can formats can also be retrofitted at a later date. Further options include the cardboard blank feed, that can be largely automated on request, and alignment of the finished packs that exit the machine and travel on to the palletizer on one, two or three lanes. With a capacity of up to 108,000 cans per hour, the Innopack Kisters CNP operates in the high-performance range and produces up to 450 packs of four a minute.

The printed TopClip covers are folded up and also clipped under the can rim to close the pack.

Here, packs of four leave the Innopack Kisters CNP with their TopClips fully folded and sealed.

Broad spectrum

With its new machine concept, as pioneer and partner to the beverage industry KHS is consistently pursuing its philosophy of offering its clients an extremely broad spectrum of secondary packaging systems – in full accordance with the bottler’s or canner’s wishes and requirements.

“Optimizing packaging systems and solutions and thus saving on materials and energy has always been one of KHS’ core activities,” Sören Storbeck emphasizes. “In this context the Carton Nature Pack, which we can offer our customers as a holistic packaging and automation system, is thus a further game changer for the beverage industry.”