The advance of automation

Intelligent technologies are finding their way into all areas of beverage filling: automated processes boost efficiency and reduce the amount of operator intervention and the number of associated potential errors.

For the fastest possible format changeovers right down the line

The KHS InnoPET iflex shortens conversion times for an entire non-returnable PET line to 30 minutes. This will delight beverage bottlers facing an ever increasing number of SKUs.

Click here for the article: No time to lose

For more flexibility plus greater efficiency

The example of the stretch blow molder/labeler/filler nlock illustrates how automated format changeovers on the InnoPET iflex function in detail and how they can save time.

Click here for the article: Flexible and efficient

For powerful keg washing and racking

DKHS'Transversal kegging line gives operators more felxibility, greater efficiency and higher performance - partly because the system adapts to the various formats fully automatically.

Click here for the article: Straight down the middle

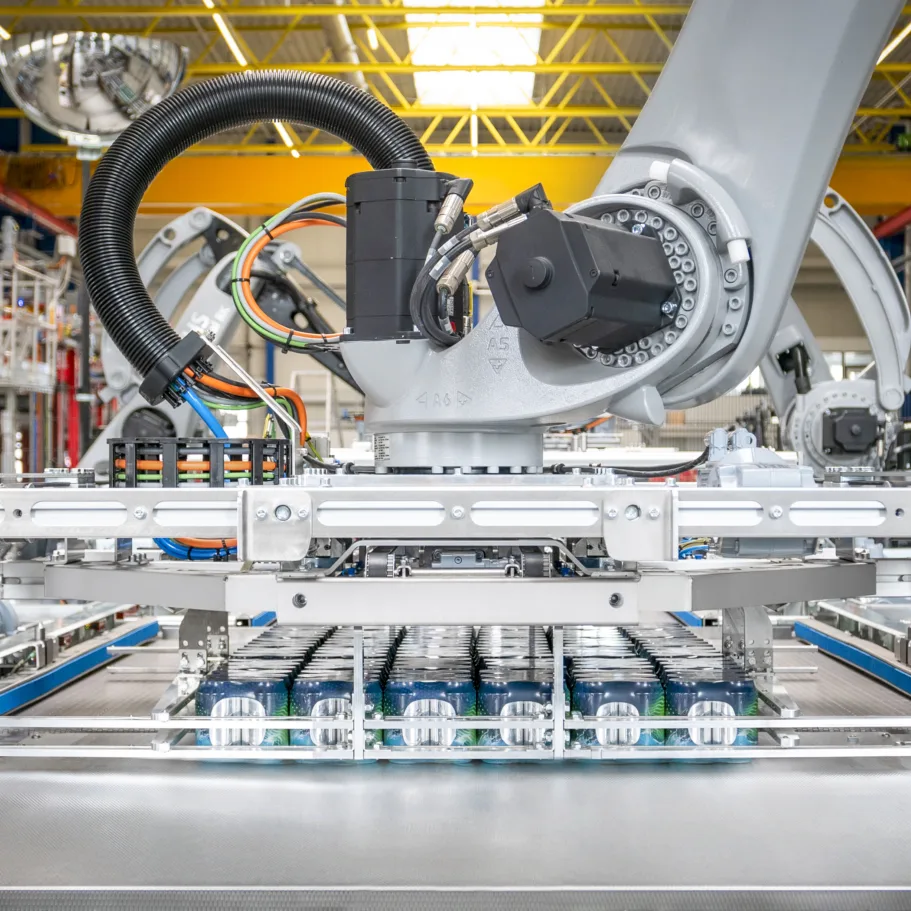

For even better hygiene and simpler operation

With many of its function now automated, the SmartCan filler/seamer block by KHS/Ferrum scores on optimum hygiene, greater flexibility and efficiency and simple operation.

Click here for the article: Come together

For a high-performance palletizing with a low infeed

With the Innopal PLR KHS demonstrates that modern robots can be brought up to speed and integrated into an innovative and efficient palletizing system with a high degree of availability.

Click here for the article: Full speed ahead