Straight down the middle

With its unique concept KHS gives operators greater flexibility, efficiency and performance when washing and racking kegs. And that’s not all: if required, the system can adjust to different formats fully automatically.

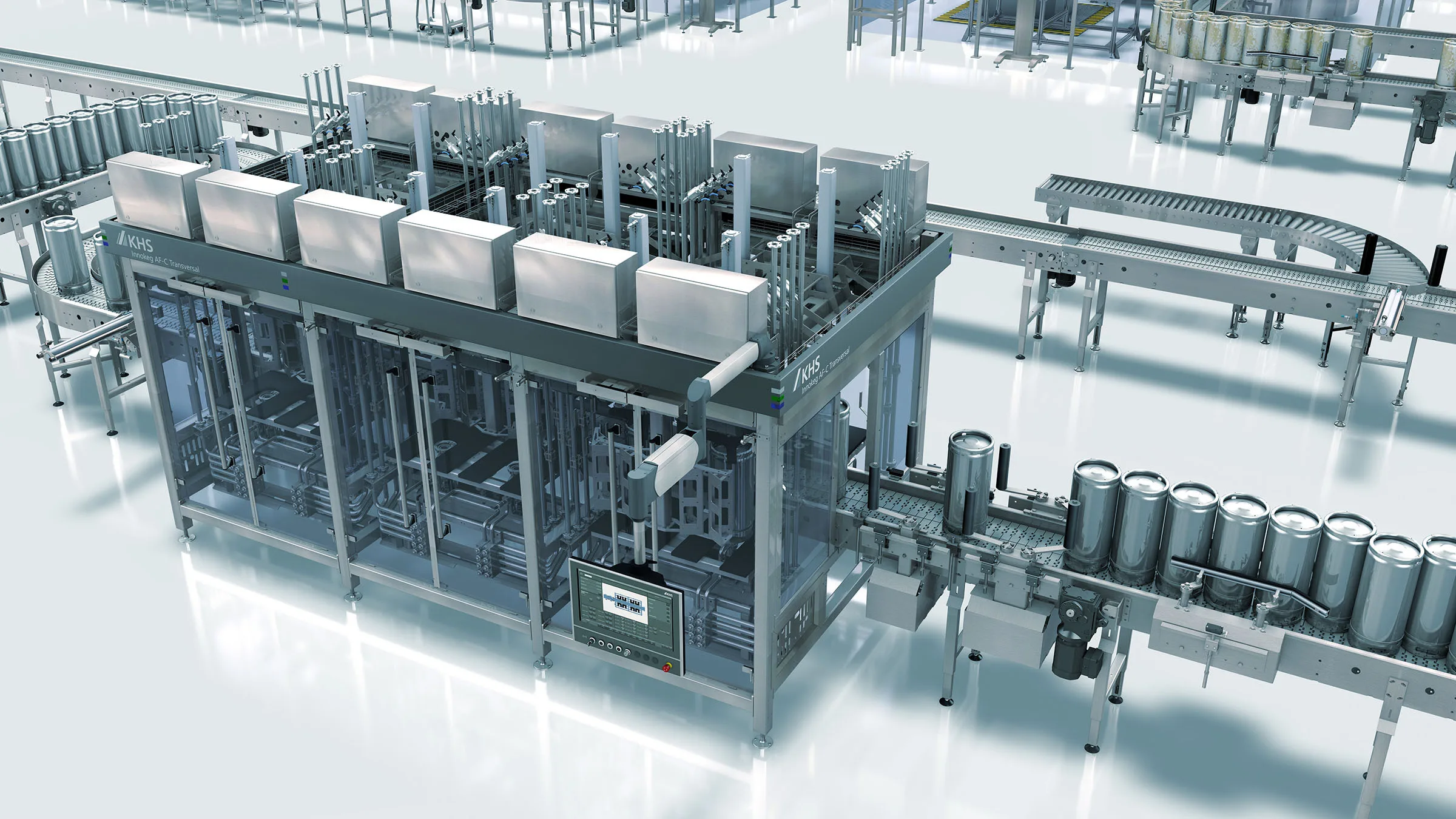

The KHS Innokeg AF-C Transversal keg system scores over standard market systems on several counts: the biggest and most obvious difference lies in its innovative conveying system. The conventional transversal conveyor setup used to date has separate belts for infeed and discharge upstream and downstream of the actual machine. The KHS design is consciously different and transports the kegs through the middle of the paired opposite processing stations on a single conveyor belt.

At a glance

Innokeg AF-C Transversal

Less space needed thanks to the central conveyor segment

Optimum access for maintenance and repair

Modular design for flexible expansion

Suitable for almost all market-standard returnable and non-returnable kegs

Fully-automatic adjustment to different formats

Up to 500 kegs per hour

On this they are pushed in and out of the line to the side. The great advantage of this concept is that on the Innokeg AF-C Transversal there are no conveyors separating the operator from the machine. The stations are thus freely and much more easily accessible for maintenance and repair. The space-saving system also has a smaller footprint in the production shop. Moreover, with its inverse ratio of conveying to processing stations (compared to standard machinery) the KHS system is more powerful and can process up to 500 kegs per hour.

»A block frame accommodates two modules with two respective processing stations and is so compact that it fits into a standard overseas container.«

Keg product manager

You can find more information about our Innokeg Transversal AF-C kegging system plus an illustrative video on khs.com

Modular and flexible

Another key difference of KHS’ keg engineering is its modular design that means lower procurement costs and that the Innokeg AF-C Transversal can grow to accommodate rising production capacities. “We combine two modules with two respective processing stations in a single block frame. Thanks to its compact design the block fits into a standard overseas container,” is how keg product manager Roger Daum explains the principle of the system. Within this frame all kinds of cycle are feasible. “A machine can be configured with up to four blocks with two modules each. This is equivalent to 16 treatment heads that can function as a pre-, main or combined washer or filler respectively,” Daum emphasizes. This provides plenty of scope when configuring the overall line: twelve washing stations can be combined with eight racking stations, for instance, to balance the different cycle times. Individual modules in the block can initially be left empty and simply fitted with further processing stations at a later date should the necessity arise.

All-rounder for all formats

Another distinctive feature of the KHS Innokeg AF-C Transversal is that it can process practically all standard market container sizes and formats. Apart from the fact that no format parts have been used anywhere on the conveying system, thus rendering changeovers superfluous, if required the entire line can be automatically adjusted to different keg heights and diameters at the press of a button on the HMI. This is performed with speed and precision. The system also recognizes whether the incoming kegs are returnable or one-way containers. The latter travel straight to the filler through the deactivated washing machines without any conversion or treatment. “It’s actually quite simple,” smiles Daum.

The counterflow and pulsed cleaning processes yield optimum results in the kegging line washing stations.

Our animation provides a summary of all process steps on the fully automatic KHS Innokeg AF-C Transversal line

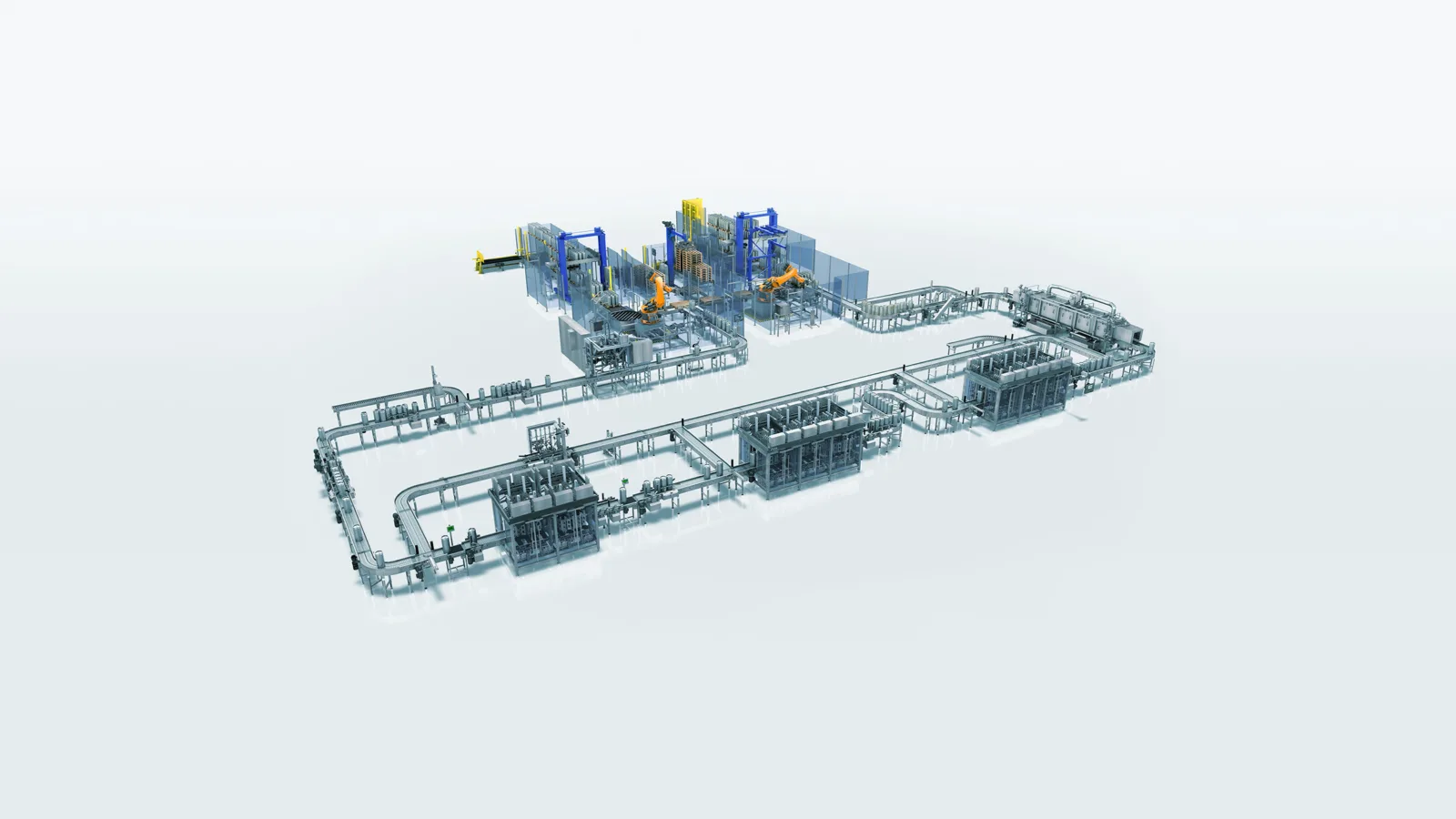

Right down the line

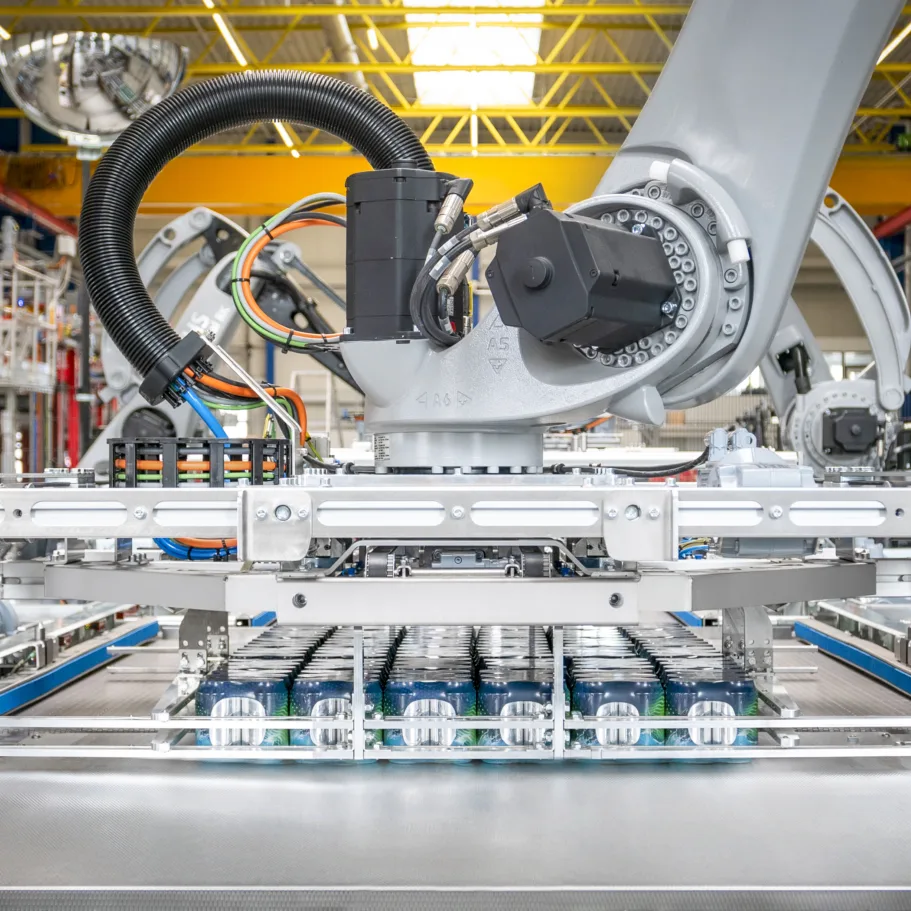

Before the kegs on the kegging line reach the Transversal modules, they are lifted from the pallet by the KHS Innopal RK palletizer with its six-axis articulated robot and placed on the conveyor. An on-demand turner with a fitting position detector and decapper ensures that the kegs are properly aligned and prepared for washing and racking. They are again separated and centered prior to exterior washing. In the washing machine a height control unit makes sure that slim kegs especially aren’t downed by the high water pressure of the cleaning nozzles.

The counterflow and pulsed cleaning processes yield optimum results at the pre- and main washing phases. Between these two steps the kegs are filled with caustic and left to soak, with the length of the conveyor determining the duration of the soaking time.

Filling is precise and regulation-compliant thanks to the KHS Direct Flow Control filling system and gross/tare weighing that complies with the European Measuring Instruments Directive. Finally, ‘bad’ kegs or incorrectly filled containers where the valve leaks, for example, are emptied and removed from the line.

The kegs are then checked for leakage and discharged if necessary before intact kegs are again turned, sealed with a cap and labeled by inkjet. At the end of the line the kegs are set down on pallets by a second KHS palletizing robot. This is equipped with double keg grippers whose heads can also be changed over fully automatically. This means that when it comes to efficiency and flexibility, KHS scores on the washing and racking of kegs right down the line, so to speak ...