No compromise

For beverage manufacturers who process a wide variety of brands and small batches, printed cans are often an expensive, space-consuming proposition. Labeling cans promises greater flexibility and lower costs, as the example of Scottish craft brewer BrewDog demonstrates.

With sales of around €200 million Scottish craft beer producer BrewDog, founded in 2007, is Great Britain’s largest independent brewery. This highly unconventional company also boasts many more impressive figures: over the past ten years annual growth rates have ranged from 51% to 87%, making the craft brewery one of the fastest growing businesses in the country. BrewDog beers aren’t only brewed at its headquarters in Ellon, Scotland, but also in the US, Germany and, as of next year, in Australia and China. BrewDog products are consumed in more than 60 countries – including at the nearly 80 BrewDog bars owned and operated by the brewery worldwide.

At the time of writing, an end to this rapid expansion is nowhere in sight. For 2019 the two founders James Watt and Martin Dickie expect an output of up to 650,000 hectoliters, spread out across a portfolio of around 100 products. In terms of volume seven headliner beers have the lion’s share, first and foremost Punk IPA which alone contributes more than €40 million to group sales in the UK. One important aspect of the brewers’ brand image as ‘craft punks’, however, is their multitude of experimental beers and seasonal specialties inspired by the changing seasons. These include, for example, a white IPA and a wintry spiced amber ale. Products such as these are sometimes filled in small and very small batches of between 5,000 and 15,000 cans, placing high demands on flexibility in production and filling.

»We’re nor able to offer a much greater selection of beers in small batches in the short-term.«

Production Projects Manager, BrewDog

Simple solution

“We have to accept minimum orders of 250,000 printed empty cans per unit,” explains Alain Atmouni, production projects manager at BrewDog. “This means that small batches either become disproportionately expensive or we have to stockpile vast quantities of empty cans at a correspondingly high cost.”

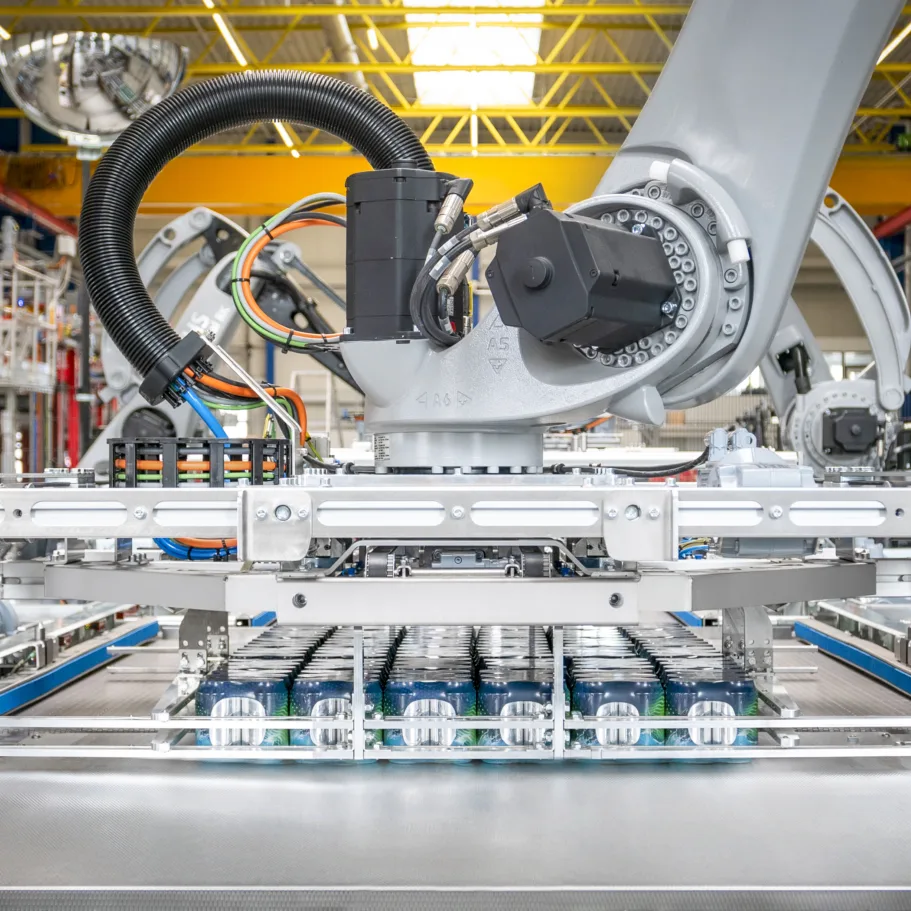

Part of the new canning line at BrewDog: the Innoket Neo labeler has been positioned upstream of the rinser and filler.

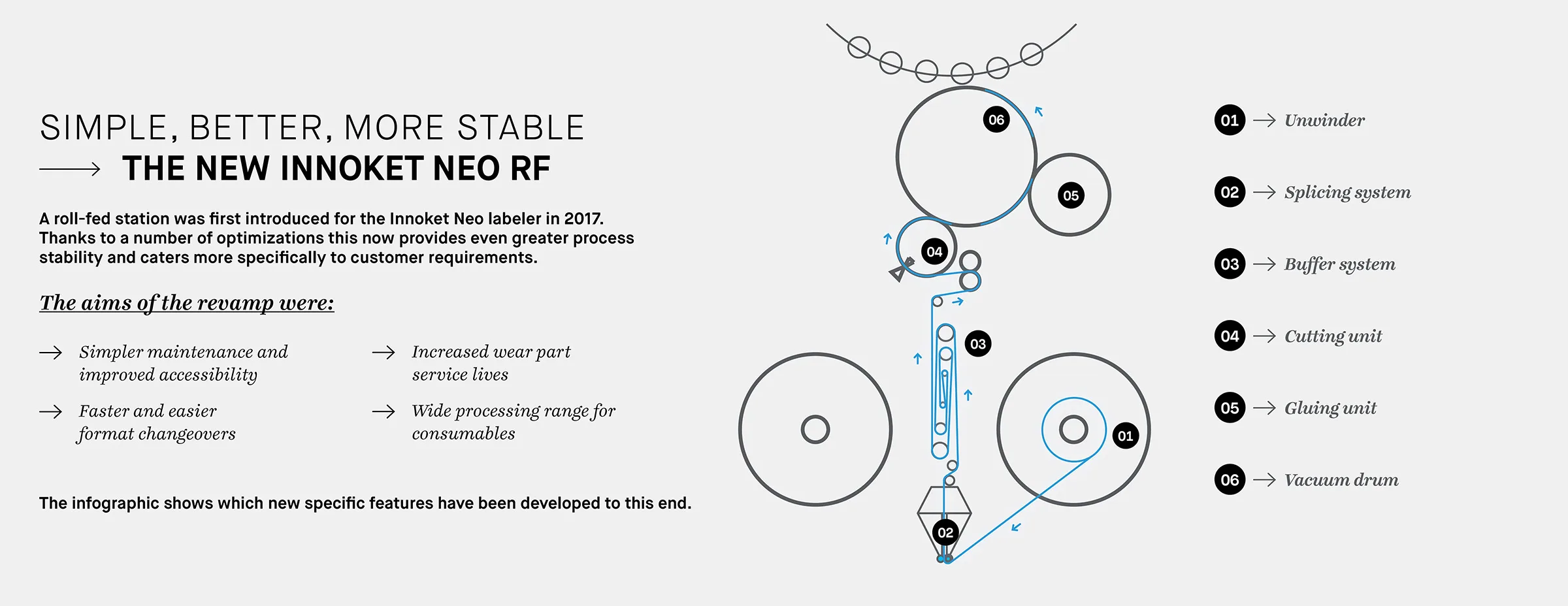

Here, KHS offers a surprisingly simple solution which BrewDog has been very familiar with since 2015 when its first canning line was installed. “For manufacturers with a great variety of brands and small batches we also provide our proven Innoket Neo labeler for cans,” says Cornelius Adolf, labeling product manager at KHS in Dortmund. “As we configured the machine accordingly from existing components, we were able to realize this further development within a very short time indeed. The Innoket Neo is designed as a modular system to cover a wide range of requirements that are becoming more and more specialized in the beverage industry.”

The Scots’ high quality standards proved to be a particular hurdle: their craft beer is neither filtered nor pasteurized but instead bottled at a temperature of 2°C. Any external influences that would alter the product must be ruled out. Because the full cans can’t be dried in the warmer before the pressure-sensitive label is applied, they have to be labeled empty.

Cornelius Adolf explains how this works. “Since the empty cans are relatively unstable without lids, we stabilize them with sterile air using a special bell to prevent the sides from being pressed inwards when the labels are applied. The cans are then rinsed out in the rinser before they enter the filler.”

Great flexibility

The customer, for whom the possibility of labeling the tinplate containers creates ideal conditions for seasonal small batch production, is also satisfied. “This allows us to make our production much more flexible and offer a far greater selection of beers in small batches in the short term,” Atmouni happily states.

Yet another challenge is the size of the label which must be longer than 21 centimeters in order to completely encompass standard 330- and 500-milliliter can formats. Despite this limiting factor, Cornelius Adolf is proud that the machine is able to process up to 35,000 cans per hour. With this system, KHS has expanded its portfolio to include a system for decorating cans with PSLs in this capacity range. Quick, tool-free format changeovers reduce setup times considerably. With its low power consumption the labeler scores with high energy efficiency. This is a real plus that is also well-received by the company which works with a dedicated continuous improvement team to cut power consumption throughout the plant, reduce the company’s carbon footprint and generally make the brewery more efficient.

»The Innoket Neo is a modular system that covers a wide range of requirements.«

Labeling product manager at KHS

Shorter time to market

Although the Innoket Neo installed at BrewDog in early 2019 as part of KHS’ second line is the first machine of its kind, this principle can be adapted to any commercially available beverage can type. Within just a few hours the packaging design can be changed and the containers decorated with suitably designed labels. “If they wish, customers can even print their own labels themselves,” Cornelius Adolf emphasizes. “This also significantly shortens the time to market.” The KHS labeler is able to process self-adhesive film and paper labels. Partial or complete labels can also be applied to the containers. The labels can be optically aligned. And because the machine can be located upstream or downstream of the filler, both full and empty cans of all standard sizes can be labeled.

To get back to BrewDog: a core tenet of their philosophy is never to compromise on quality. It’s thus all the more fitting that this beer producer has found a partner in KHS who’s the world market leader in can filling when it comes to hygiene, filling accuracy and oxygen pickup. Since the focus is also on flexibility, the brewery can of course also fill pre-printed cans on the new line if higher quantities make this economically feasible.

A KHS Innofill Can DVD can filler, BrewDog’s second, forms the heart of the new line.

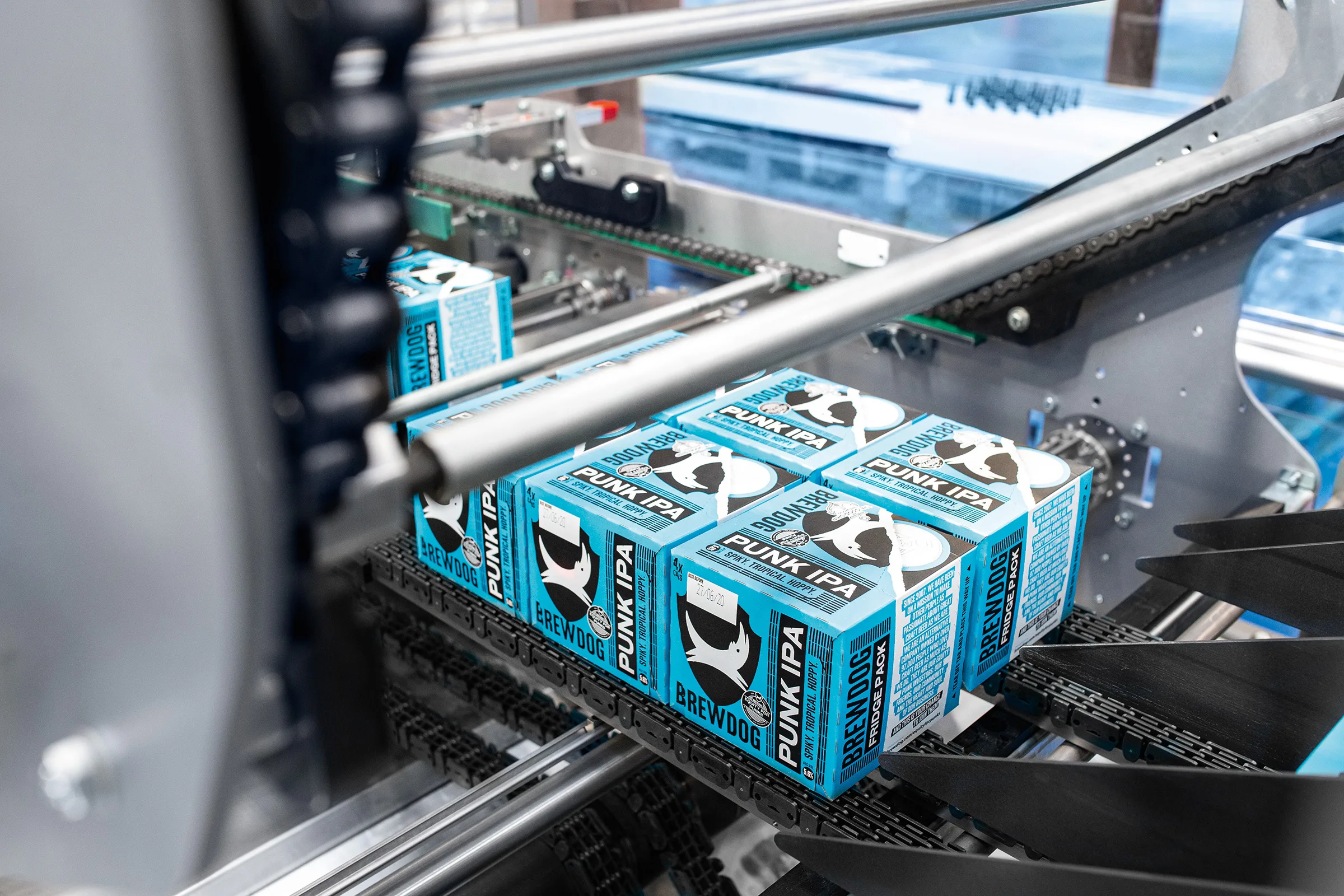

Large batches as also filled on the new line, albeit into printed cans: here, BrewDog’s headliner Punk IPA.