Every drop counts

Since we can’t do without water to survive, it’s absolutely vital that we use this precious resource responsibly. KHS supplies the beverage industry with efficient systems and solutions for the entire filling process to help save water in the long term.

The numerous resources that are consumed in the production and bottling of beverages include electricity, carbon dioxide and nitrogen – and of course water. It’s not only a basic ingredient; it’s also an indispensable operating material used for cooling, lubrication and cleaning. Above all, however, it’s the basis of all life. More than 70% of the human body is comprised of water and it’s crucial for our health: without it there’s no drinking water, no agriculture, no seas, lakes and waterways of fish for human consumption and no rivers for transporting goods – and thus no industry.

Water shortages as a potential for conflict

In light of climate change and increasing global warming, the responsible use of this precious limited resource is becoming increasingly important. This is shown by examples in South Africa (see the article “Small footprint”) or in other parts of the world, where prolonged periods of dry weather first cause emergencies and then bring about unrest. “I’m personally convinced that water shortages will lead to conflicts between regions and even nations in the near future, the escalation of which can’t be ruled out,” says Siegmar Stang, executive vice-president of the Filling Technology Product Division at KHS, describing his view of the future. “When water becomes scarce and people have nothing more to drink, this opens up new potential for social and political conflict.” That’s why he and his team have set themselves the goal of conserving every single drop of water that’s not absolutely necessary for the product and various production processes. The consumption of water resources should be reduced to an absolute minimum in beverage production without neglecting the necessary hygiene.

With a series of measures, Dortmund systems provider KHS is creating the conditions required to achieve this goal. True to the motto of ‘small cause, big impact’, it’s often optimizations in detail that bring about major results in the long run. “In the end, it all comes down to the total sum of further developments,” says Stang. “This has a decisive effect on customer operations and helps them to operate their own plant as sustainably as possible.”

Solutions

CHAMPION SAVER*: Mixer (CSD) processing up to 72,000 liters per hour

WATER SAVINGS PER YEAR – UP TO 1.2 MILLION LITERS

How: vacuum pump kept at a constant temperature cooled by an internal closed circulation system.

CHAMPION SAVER*: Stretch blow molder/filler block processing 36,000 1.5-ml bottles per hour

WATER SAVINGS PER YEAR – UP TO 33 MILLION LITERS

How: elimination of the PET rinser.

CHAMPION SAVER*: Bottle washer processing 50,000 500-ml bottles per hour

WATER SAVINGS PER YEAR – UP TO 32 MILLION LITERS

How: specially designed carrier systems that carry over less heat and thus reduce the cooling requirement.

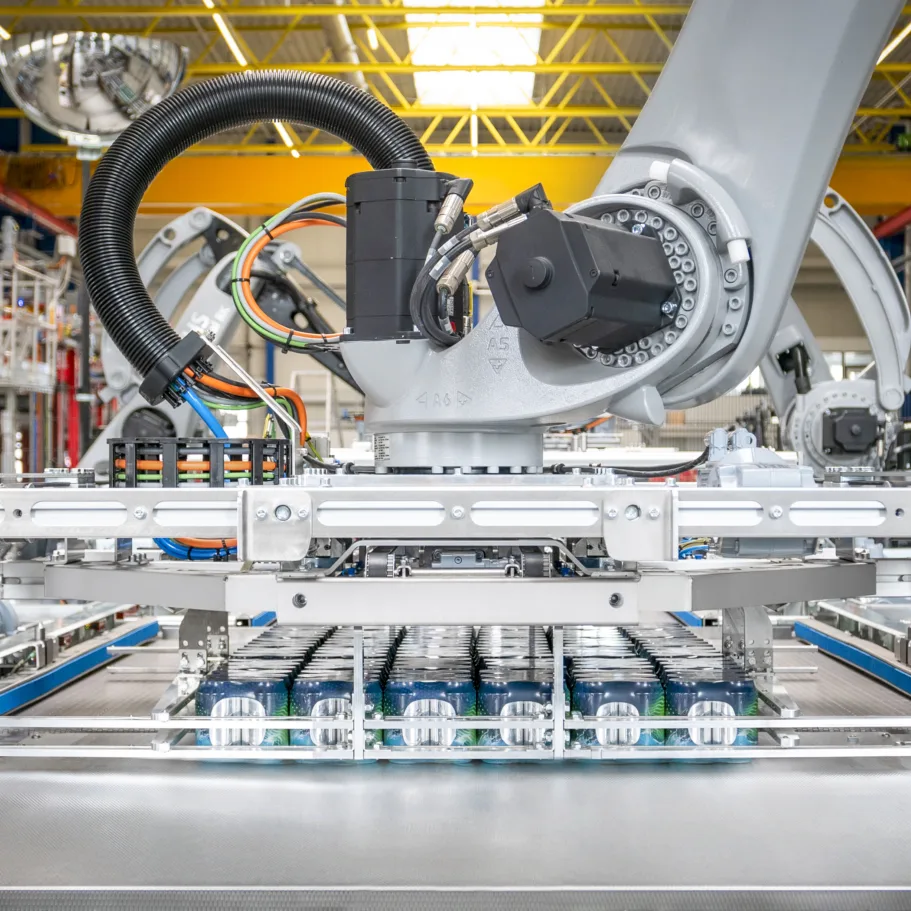

CHAMPION SAVER*: Can filler processing 70,000 cans per hour

WATER SAVINGS PER YEAR – UP TO 1.2 MILLION LITERS

How: water-free roller lubrication, expansion bellows instead of sliding seals.

CHAMPION SAVER*: Glass bottle filler (beer, CSD) processing 50,000 bottles per hour

WATER SAVINGS PER YEAR – UP TO 2.5 MILLION LITERS

How: new hygienically-designed bottle shower.

CHAMPION SAVER*: Glass bottle filler (beer) processing 50,000 500-ml bottles per hour

WATER SAVINGS PER YEAR – UP TO 10 MILLION LITERS

How: vacuum pump kept at a constant temperature cooled by an external system.

CHAMPION SAVER*: Flash pasteurizer processing 60,000 liters per hour

WATER SAVINGS PER YEAR – UP TO 2 MILLION LITERS

How: intelligent shift register.

CHAMPION SAVER*: Tunnel pasteurizer (beer) processing 105,000 330-ml bottles per hour

WATER SAVINGS PER YEAR – UP TO 25 MILLION LITERS

How: speed control and cooling tower that ensure maximum pasteurizer efficiency.

On khs.com you can learn more about how you can get the best out of your machines with line optimization.

Hygienic design

One example field of action centers on hygienic design. “We pay particular attention to the easy-clean design of our systems: by eliminating dead spots, offering no-frills machine designs and using high-alloy, corrosion-resistant steel with a low surface roughness we prevent the buildup of deposits,” explains Stang. “This facilitates cleaning and shortens the duration thereof – which not only means using less water and cleaning media but also saves on energy. In addition, the machine is ready for production again more quickly.” The list of the various aspects of hygienic design is long. The design has no corners or edges. The new filler platforms from KHS no longer have front tables. Ducts and passages are shaped, welded seams are arranged and seals are placed in such a way as to prevent the accumulation of deposits which could possibly lead to contamination. Flushing water is able to access all surfaces without obstruction and clean them without leaving any residue.

In other areas, the machine design ensures that in terms of hygiene water can even be dispensed with entirely. Servotechnology and pneumatic equipment, for example, replace the wet-lubricated mechanical cam and roller parts previously used in KHS can fillers. “The more intelligent our design, the less water our customers use,” Stang sums up. In this respect, the fact that as one of the world’s largest soft drink manufacturers KHS has been able to reduce water consumption per liter of finished beverage from 2.86 liters to 1.61 liters in the last 15 years can be confidently considered proof of the company’s innovative strength.

»The more intelligent the design of our machines, the less water our customers use.«

Executive vice-president of the Filling Technology Product Division, KHS

Multiple use

The hygienic design alone, however, is far from being the sole source of consumption savings. “Another major lever is the multiple synergetic use of circular flows,” stresses Stang. Examples include also using heated water from the vacuum pump in the crate washer, process water in heat exchangers and evaporation energy for cooling. Technology from KHS makes it possible to limit the volume of wastewater to the greatest possible extent and thus also reduce the beverage industry’s carbon footprint. Ultimately, water treatment is a process that requires a considerable amount of energy. Every reduction in consumption in this area therefore also reduces greenhouse gas emissions and ensures a better ecological balance.

Lower consumption and costs

Beverage manufacturers, however, are generally more likely to be swayed by economic motives. “Here, the focus is usually on TCO**,” says Stang. “Our customers operate in high-investment supply chains with extremely large throughputs. Each and every minute of availability that takes up less time for cleaning counts; each machine downtime means lost revenue.” All of the measures KHS develops to reduce water consumption are intended to help beverage manufacturers cut their costs and use of resources throughout the life cycle of the entire filling line. This also boosts their machine performance and the company’s added value. In addition, regulatory frameworks are increasingly influencing water management in industry both directly and indirectly. From the CE mark and TÜV certification to the strict requirements of governments or institutional bodies, the bar for saving resources is being set higher and higher.

However, it’s often the consumer who forces companies to act. One example of the aforementioned potential for conflict recently occurred in the north of Mexico, where a large brewery was to be constructed in a region with scarce water resources. In view of the expected disproportionately high water consumption, resistance was considerable. Both the city dwellers, who depend on drinking water, and the farmers, who need a sufficient supply of water to cultivate their fields, protested until the company finally backed down following a referendum. Although more than half of the investment sum had already gone into the construction of the plant, the group abandoned its plans and is now looking for a new location.

Many companies have learned from this and are not only relying on CSR programs*** on their markets to supply the population with clean drinking water; what’s referred to as the ‘water footprint’ is also becoming increasingly important to them. Carlsberg, for example, has set itself the goal of reducing its water consumption in beer production by 50% by 2030. Other big players, from brewery groups to soft drink manufacturers, are making similar voluntary commitments which they intend to actually implement – also with the help of technology from KHS.

* Based on 6,000 hours of production per year.

** TCO = Total Cost of Ownership.

*** CSR = Corporate Social Responsibility: voluntary contribution of companies to sustainable developments that go beyond legal requirements.