A tradition of creativity

In the late 1950s in Kleve an inventor and his diligent wife set up a think tank for packaging machines. They quickly went from garage workshop to worldwide innovative leader – in a sometimes rather bizarre story with many ups and downs.

At KHS in Kleve about 150 packaging machines a year on average leave the production shops, with one machine a day occasionally being shipped during the peak season between November and April. This is when beverage producers tend to upgrade their technology prior to the busy summer months so that they can concentrate exclusively on bottling and distributing their products once the season is underway. However, the prime focus of the packaging experts from the Lower Rhine isn’t just the capacity but also the technological innovative force of the company – and this boasts a long tradition.

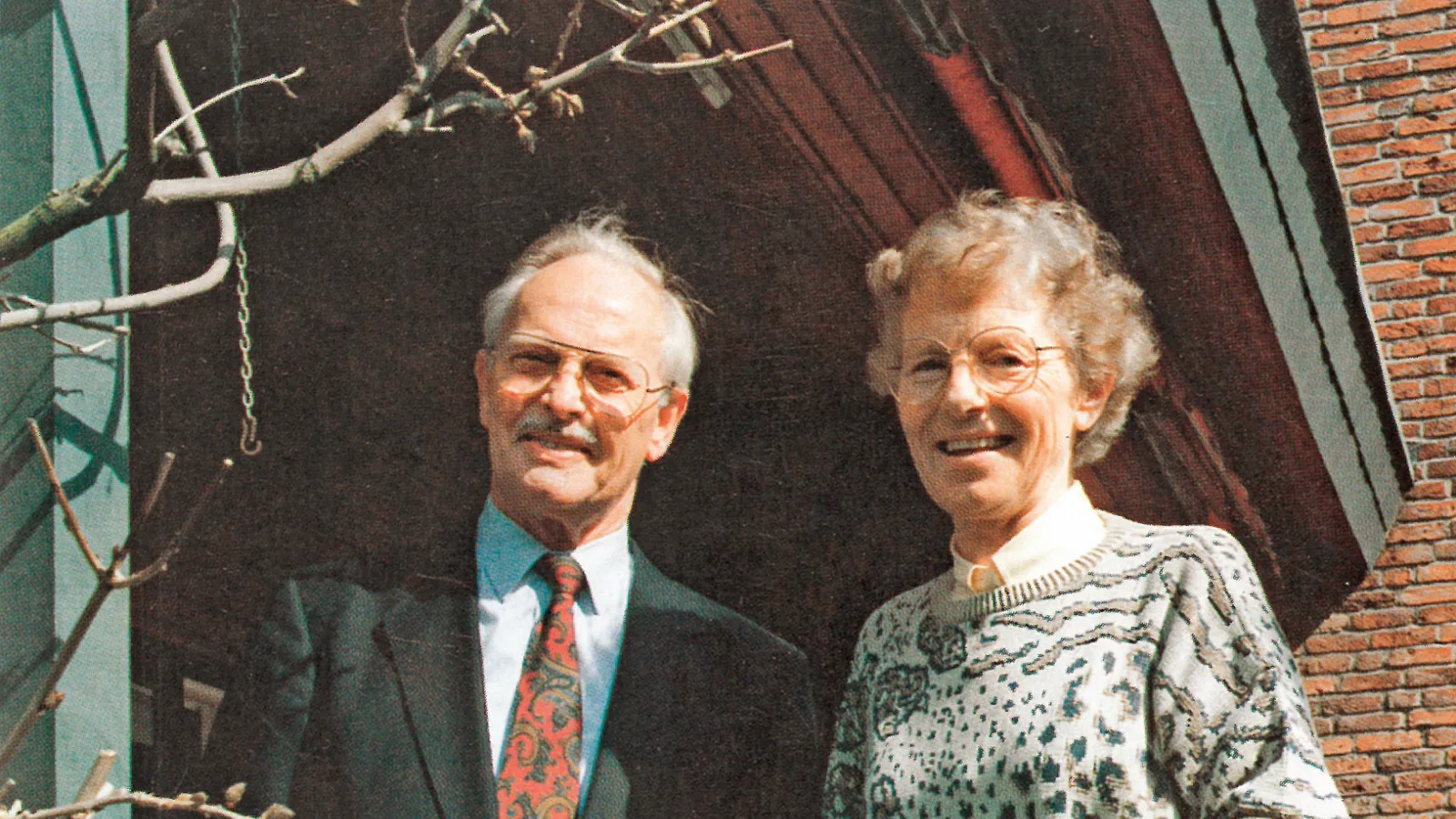

The company was founded in 1957 by husband and wife Karl and Maria Kisters, he an experienced master mechanic and she a businesswoman with a very good grasp of technology. At their garage workshop with just two additional employees they manufactured machines for local industry, in particular for children’s shoemaker Elefanten where Kisters was an apprentice in the metalworking shop. The company quickly turned its skills to other products, among them XOX, a major producer of cookies and crackers based in Kleve. Within a few years gingerbread cutting machines, film-wrapping and gluing units for chocolate candy boxes, waffle folding machines and a peanutflavored chip machine were also included in the portfolio.

Karl Kisters’ credo from very early on was “What we make must last forever!” This not only expressed his high demand for quality but also the fact that Kleve, due to the lack of an extensive service network at that time, would rather not hear anything more about a machine in its next 20 years once it had left the factory.

Karl Kisters (1924-2008)

moves from Straelen to Kleve to begin his apprenticeship as a mechanic in 1937. After the war he lives at the Kolpinghaus in Kleve during his master craftsman training. This is where he meets his future wife Maria van den Boom.

A sense of humor

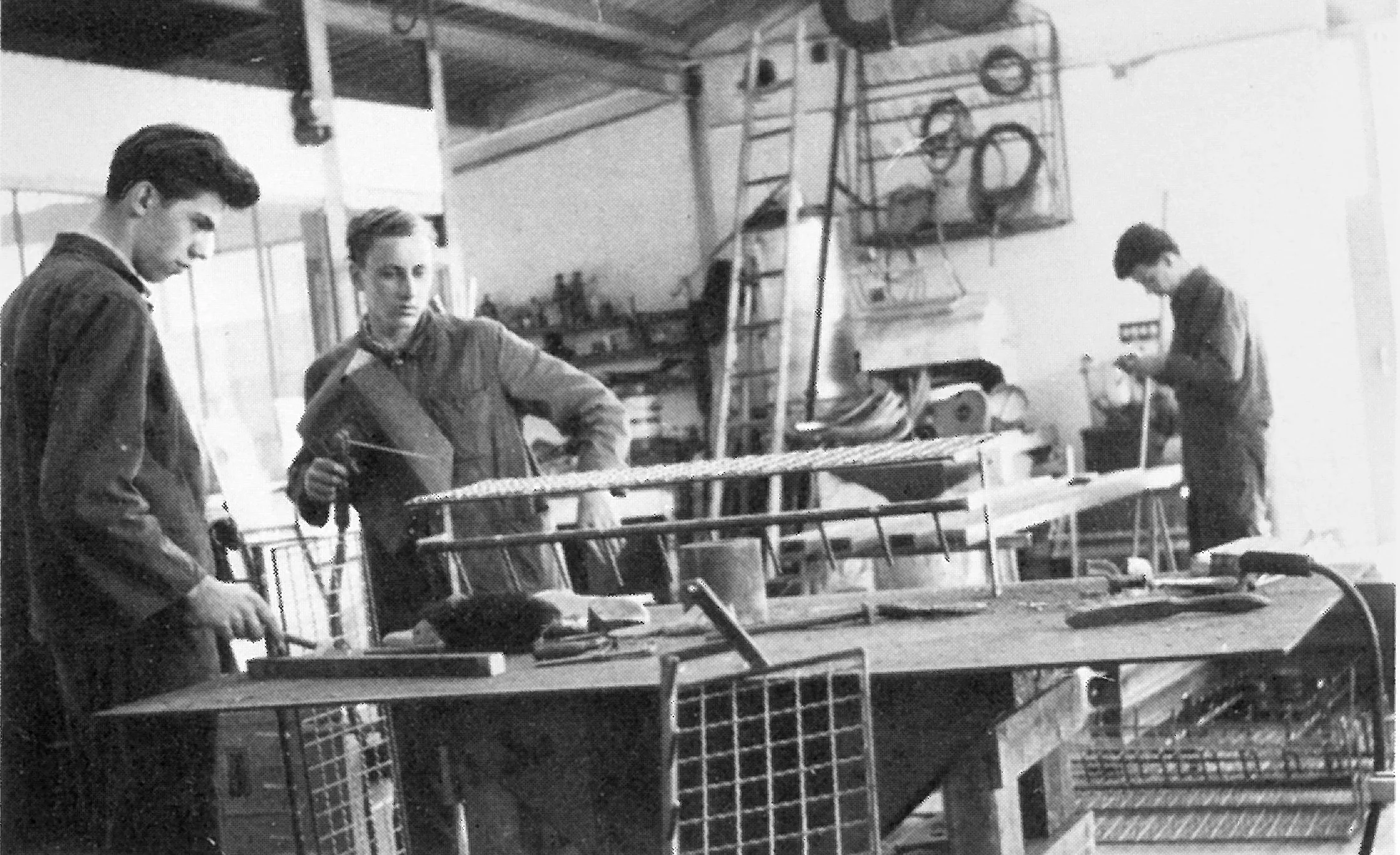

Not everything went smoothly on the first attempt, however. Franz Grunenberg, who started his apprenticeship as a metal worker at Kisters at the age of 14 in 1962, has this to say about a certain butter cookie machine: “The cookies went into chutes and were pushed into the little boxes with the help of cutters. Since the cookies weren’t all of the exact same thickness back then, there were a few teething problems. This is why we also called the machine the “cookie breaker”,” he reminisces. Karl Kisters was also a man with a sense of humor. “At work we had a bell which on Mondays rang for each machine sold the previous week. Each machine had its own ring tone,” says Grunenberg. “The entire workforce therefore knew not just how many machines had been shipped to customers but which ones.”

Karl Kisters’ affinity with technology and his joy of experimentation were by no means limited to his company alone. Together with his apprentice Grunenberg he once constructed a remote-controlled “gunboat” powered by liquid fuel which contained firecrackers, a fuse and mufflers and undertook its maiden voyage in a flooded gravel pit. On another occasion a return journey from a trade show in France had to be interrupted so that an old radio could be salvaged from the roadside. This was later used for “research purposes”. It’s thus no wonder that Grunenberg sometimes felt like the son the Kisters never had. The atmosphere at Kisters was so familial that the employees respectfully referred to the boss and his wife as “father” and “mother”.

Despite all the fun Kisters is an exceptionally serious and extremely successful company. In 1970 Werner Oster began training as the first apprentice electrician at the fast-growing company which even then was heralded as being extremely progressive. “In the 1960s Kisters in Germany was the first manufacturer of packaging machines that could run a number of different applications. Thanks to their interchangeable format sets which could be switched over in just ten minutes, companies didn’t need to procure a second machine. This gave Kisters a unique position on the German market at that time,” states the former head of Project Processing who retired in 2017 after 46 years at the company.

The old premises are so cramped that many portable buildings have to be used, earning the company the nickname of “Kisters Hüttenwerken” or the Kisters hut works.

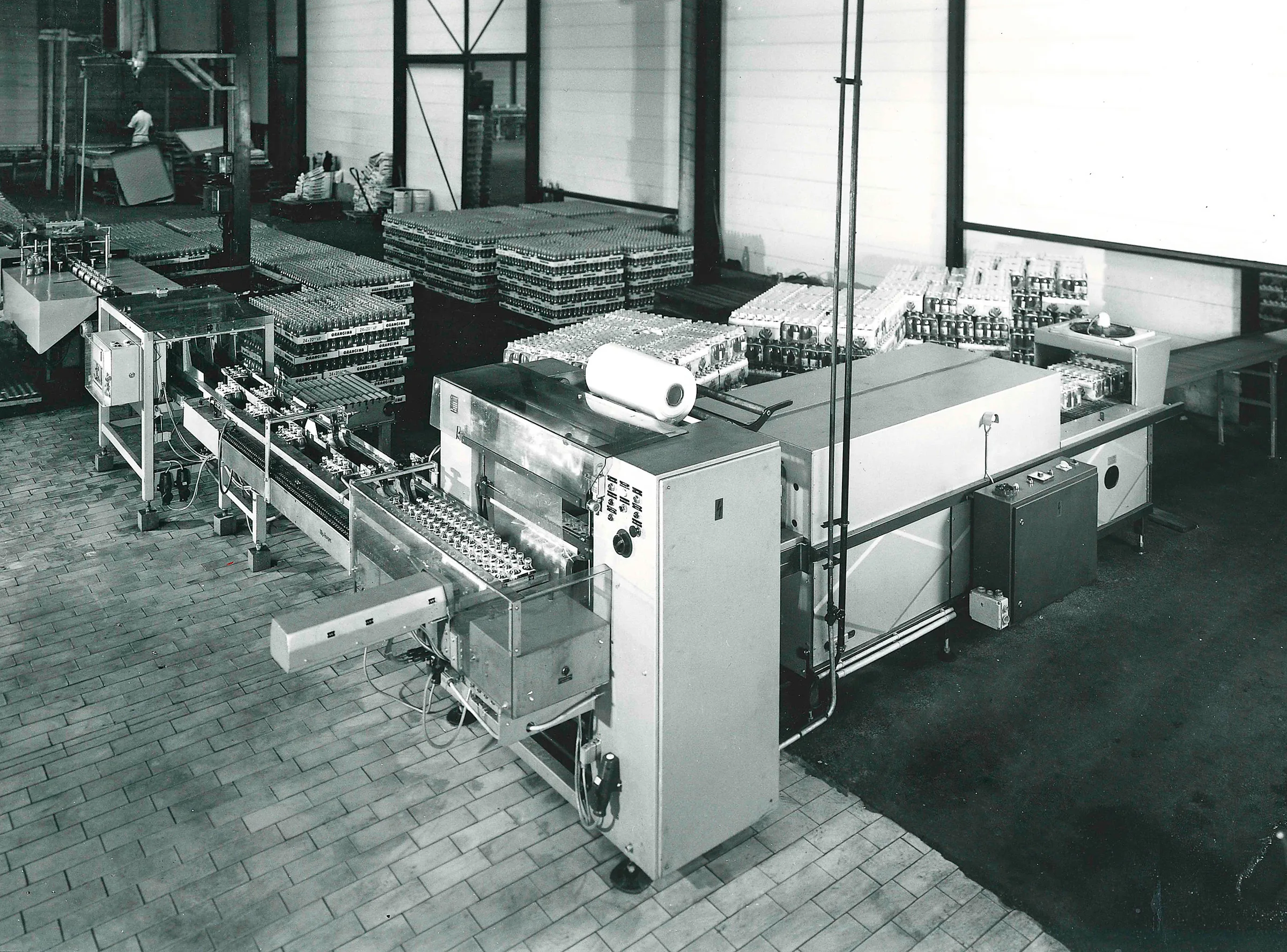

In 1968 the first multipacker for tray packs is built which makes extremely stable, robust packs either with or without shrink film. Kisters is particularly successful with this innovation in the United Kingdom.

Pioneering spirit from Kleve

In the 1970s Kisters developed the first in-house programmable logic controller (PLC) in the world, which could visually display processes, the machine status and fault messages. Oster continues, “At the end of the 1980s we were then the first in the packaging sector to use several local servo drives on one machine instead of the then standard general drive through a main shaft, for example. This was only possible thanks to our own PLC. Even back then this was designed in such a way that logical parameters, such as millimeters, seconds and minutes, could be entered in place of the otherwise usual hexadecimal entries,” he reminisces. “We also always made sure that even the finest electronics could be operated by operators wearing the thickest gloves.”

Although the company and its innovations long had international status, the company owners retained their unconventional style of management. During his travels Karl Kisters acquired orders which often presented his engineers with quite a challenge – not least because the smoker usually sketched the machine layout on the inner wrapper of his Finas cigarette box. Should his engineers on occasion not have come up with a way of realizing his ideas, on Monday Kisters would turn up at the factory with a solution he had developed in his garage at home over the weekend. Maria Kisters, responsible for the company’s commercial welfare, never came to the office without her dog – and if the boxer didn’t like someone, that person wasn’t hired. She also adopted a clear stance regarding her employees’ motivation: “People must enjoy coming to work in the mornings,” she stressed on more than one occasion. Those who belonged to the proverbial Kisters family were proud to call themselves “Kisteraners”, even when by the mid-1990s the company numbered about 500 employees and achieved an annual turnover of over €100 million.

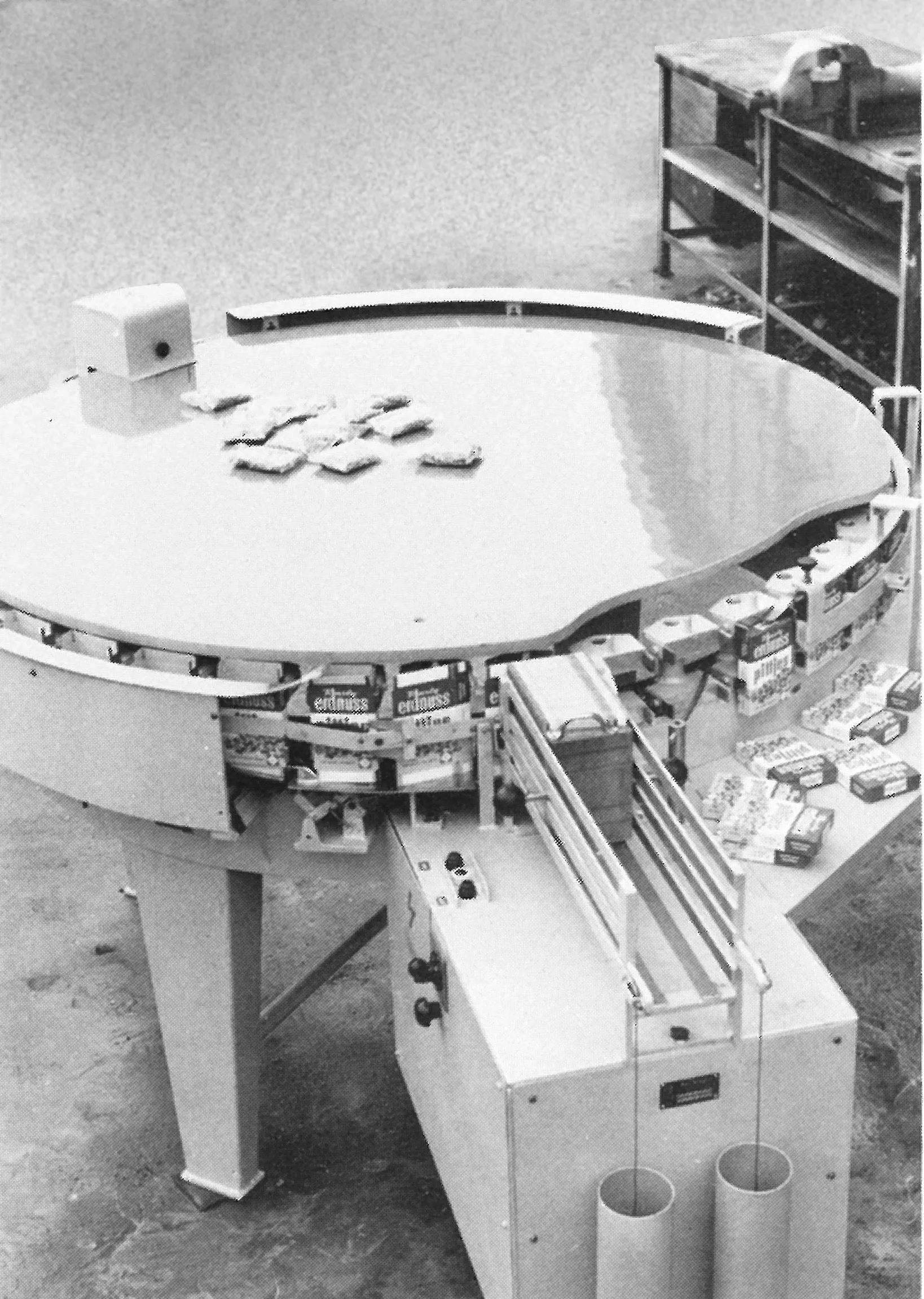

The Kisters RAKA machine, a rotary carton erector, sealer and filler for vacuum-packed peanuts from 1965.

The factory at its present 21,000 square meters site on Boschstrasse is erected in two phases between 1984 and 1988.

In 1974 Kisters develops and engineers the first continuous high-performance packer controlled by a microprocessor. At 60 cycles a minute it’s one of the fastest machines in the world at the time. The controllers are largely developed personally by Karl Kisters and Franz Grunenberg.

In order to prepare their retirement from the company, after searching long and hard Karl and Maria Kisters, who never had any children of their own, sold half of their company to Klöckner Mercator Maschinenbau in Duisburg in 1987. The major criterion was the hope that packaging machines would continue to be built at the site in Kleve and that their employees would retain their career perspectives. Five years later they sold their remaining shares in the company and retired from operative business. With the proceeds from the sales of their shares they founded the charitable Kisters Foundation.

Kisters was committed to the qualification of its employees even back in the 1960s: here, Franz Grunenberg (left) as an apprentice.

The great bond which exists between the members of the proverbial Kisters family is demonstrated by the many shared leisure activities – from the company chorus and brass band to football, tennis and table tennis clubs.

Modular system

At the turn of the millennium the launch of a modular machine concept – still in use today in a modified form – ultimately signaled a veritable quantum leap. With this concept various base modules can be flexibly combined with optional modules within three process module groups (formatting, folding and film). The new structure was such a spontaneous hit on the market that the expected number of orders was exceeded several times over in the first year.

In 2003 the company was transferred by Klöckner to the KHS Group where it was fully integrated. Administration and sales were merged with the KHS organization, resulting in adjustments to the core workforce in Kleve, with the former enterprise now run as a KHS plant. “This was a tough blow for all of us,” Franz Grunenberg claims.

Committed to the common good

The Kisters Foundation

Karl and Maria Kisters were always especially committed to the wellbeing of their employees. It was thus of prime importance to them that the Kleve site be retained following the sale of their company shares so that future generations could also perceive Kleve as an attractive place to live and work. The couple also showed great commitment outside the company, especially when it came to promoting young people. With the proceeds from the sale of their company they therefore set up the Kisters Foundation in 1999 which funds various charitable activities in the Kleve region and is especially dedicated to basic and further vocational training. Among other facilities the foundation has its own film and recording studio as audiovisual media always interested and inspired the ambitious cine-filmmaker Karl Kisters.

Long before setting up their foundation the Kisters had been devoted to the welfare of their adopted home of Kleve for many decades. The results of their commitment to the common good can still be seen on every street corner in Kleve, one such example being the new Kolpinghaus which the two entrepreneurs funded in 2001. Karl Kisters, born in Straelen on the Lower Rhine in 1924, had close ties to the Kolping Society all of his life. During his apprenticeship he lived at the Kolpinghaus in Kleve where he met his future wife Maria. The Kisters also supported the Klever Klosterpforte association, which cares for groups on the edge of society, and the building of kindergartens, were active in Kleve’s local culture and history association and paid for respiration apparatus for the neonatal intensive care unit at the hospital in Kleve.

Maria and Karl Kisters’ community spirit earned them numerous awards: they were made honorary citizens of Kleve in 2005, for example. In 2011 the readers of the Rheinische Post newspaper elected Karl Kisters the “city’s greatest personality” in a local poll – three years after his death. So great an honor may well have been a little embarrassing for the extremely modest Kisters who was never a man of big words.

In 1968 the first multipacker for tray packs with and without shrink film achieves a machine output of up to 25 cycles per minute.

New ideas

In the streamlined company, now without its founders, the old pioneering spirit was soon revived. The most recent example of this is the Nature MultiPack™, where PET bottles are stuck together by dots of adhesive instead of being packed in shrink film or cardboard. This is just one of a total of 427 patented innovations that have been developed here. Around 4,000 packaging machines from Kleve are now in operation worldwide. The oldest is from the 1980s – and some of them will continue to provide their services for many years to come.