New in filing and packaging

There’s nothing more enduring than change. This wise saying is especially relevant with respect to filling and packaging systems for the beverage industry that KHS is constantly further developing so that they meet changing market conditions and growing demands.

Innofill PET DRV adds three new extras

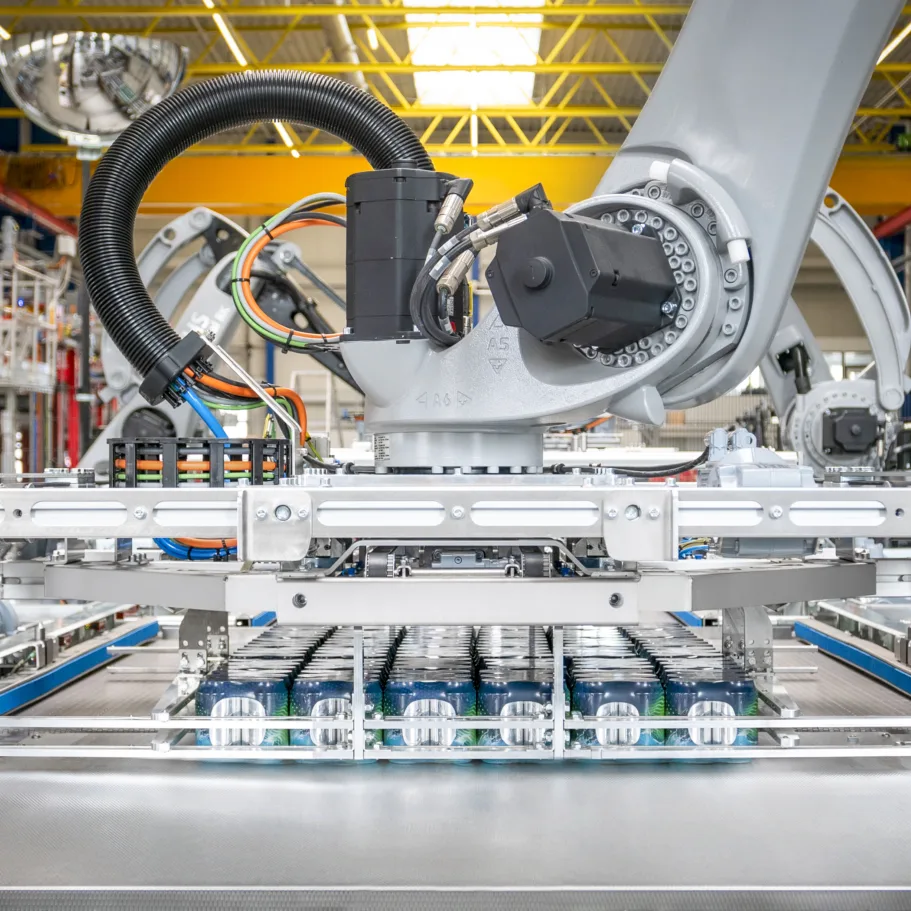

Usually part of a block system used to fill still and carbonated beverages into PET bottles, the Innofill PET DRV now scores with three new features that enable the machine to satisfy the increasing demands of the beverage industry even better.

To the article: Better and quicker

New: faster speed

With an output of up to 90,000 bottles an hour KHS has redefined its own concept of high speed in order to meet growing customer demands on the Asian market in particular.

New: high capacity for large bottles

Product bowl raised, three-step switching valve installed: these two optimizations boost machine performance with bottles holding 1.5 liters or more by up to 15% – without limiting the degree of flexibility.

New: cool base instead of cold feet

The new bottle base full jet cooling feature gives PET beverage containers adequate stability prior to pressurized filling. It’s effective, gentle on the container and uses much less water.

Adhesive: one suits all

Already in use with beverage cans, a new universal adhesive is now also available for PET bottles that simplifies handling, is gentle on containers and increases the stability of the packs during transportation. This thus considerably extends the possible uses of the environmentally-friendly Nature MultiPack.

To the article: One suits all