Bottles – do you want to live forever?

To ensure the prevalence of bottles made of rPET, not only are sophisticated collecting systems and recycling methods called for; trouble-free processing of recyclate must also be feasible. For this, KHS provides a number of special systems, solutions and services.

According to business magazine Forbes, around 140 PET bottles per head are circulated in Europe each year, with this figure more than double this at 290 in the USA. Despite all the criticism the plastic container is actually growing in popularity, with the number used increasing globally by around 4% per annum. Awareness of the need to recycle is also on the rise, however; according to Forbes, an estimated 57% of all used PET bottles were collected worldwide in 2019. For 2029 the magazine forecasts that this rate will increase to 68% – albeit with major differences from region to region. While 57% of all bottles could be collected in Europe, in the USA this would only amount to 30%. China, on the other hand, could become something of a model student and in ten years achieve an impressive collection rate of 82%. Collecting doesn’t mean recycling, however: in the USA 70% of all collected plastics end up at waste disposal sites – and in Europe 30%.

Practically made for recycling

Of the approximately 477,000 metric tons of PET used each year to make bottles in Germany alone, about 93% of this material is recovered and reused. Only roughly a third of this is reused for bottles; the rest goes into the manufacturing of films and especially textile fibers.*

* ‘Aufkommen und Verwertung von PET-Flaschen in Deutschland 2017’ (occurrence and recycling of PET bottles in Germany), GVM or Gesellschaft für Verpackungsmarktforschung (on behalf of Forum PET).

No other plastic can be as easily recycled as PET, however. PET is the only plastic whose recyclate satisfies the legal requirements governing food grade materials. In-depth cleaning removes noxious substances which the material may have absorbed during its use. Whereas with other materials, such as polypropylene, polyethylene and polystyrene, the loss of quality which occurs on application of the usual recycling methods is irreversible, recycled PET can always be brought up to the standard of new material. A recyclate of this quality is naturally also extremely popular outside the bottle-manufacturing sector. This means that the bottle-to-bottle recycling loop is deprived of a large percentage of this raw material.

»We’re consulting with all of the major plastics processors regarding the further thermomechanical processing of rPET.«

Product manager for Bottles & ShapesTM at KHS Corpoplast

There’s also the development in price to be considered: while the cost of what’s known as virgin PET is based on that of crude oil and benefits from the current low market price thereof, the charge for recycled PET has continuously risen over the last three years. Companies now have to pay about 20% more for rPET than for the original material – also because the supply can’t meet the growing demand. This is where everything comes full circle; there’s still plenty of potential for optimization in the PET collection, sorting and processing infrastructure throughout the world.

High standards of quality

There are not only a number of hurdles to be overcome regarding the raw material; some beverage producers are also still very cautious when it comes to actually using rPET. They often have reserves about the color or fear a drop in the intrinsic viscosity (IV).** Another issue concerns safety standards and thus the safeness of the material. Time and again the question is raised as to whether multiple recycling can affect the quality. Although this hasn’t yet been fully researched in practice, one thing is clear: as the polymer chains reform, no compromises must be made as regards the material quality as long as the additives can be completely separated off. The European PET Bottle Platform (EPBP) is just one of the institutions that helps to assure high standards of quality with its clear specifications and certifications.

** Intrinsic viscosity (IV) is a measure of the molecular weight of a polymer which reflects the melting point, crystallinity and tensile strength.

Water bottles produced by the share brand are made of 100% recyclate. Each bottle sold donates a day’s supply of drinking water.

Whereas just a few years ago experimentation was rife and experience with recycled PET was gained according to the principle of trial and error, the situation nowadays is greatly changed and highly professional. From a technical standpoint there’s long been nothing preventing the global use of high percentages of recycled PET; more and more beverage producers and brands are even opting to use bottles made of 100% recyclate. Where this is not yet the case, voluntary commitments are being publicized; Poland Spring, one of the huge water brands in the USA, and Evian want to use only recycled PET by 2025. The other brands by Danone Waters, Pepsi and Coca-Cola plan to have a worldwide quota of 50% by this date. The slight graying of the bottles, if indeed the consumer notices this at all, is reinterpreted as a type of hallmark of quality for sustainable packaging.

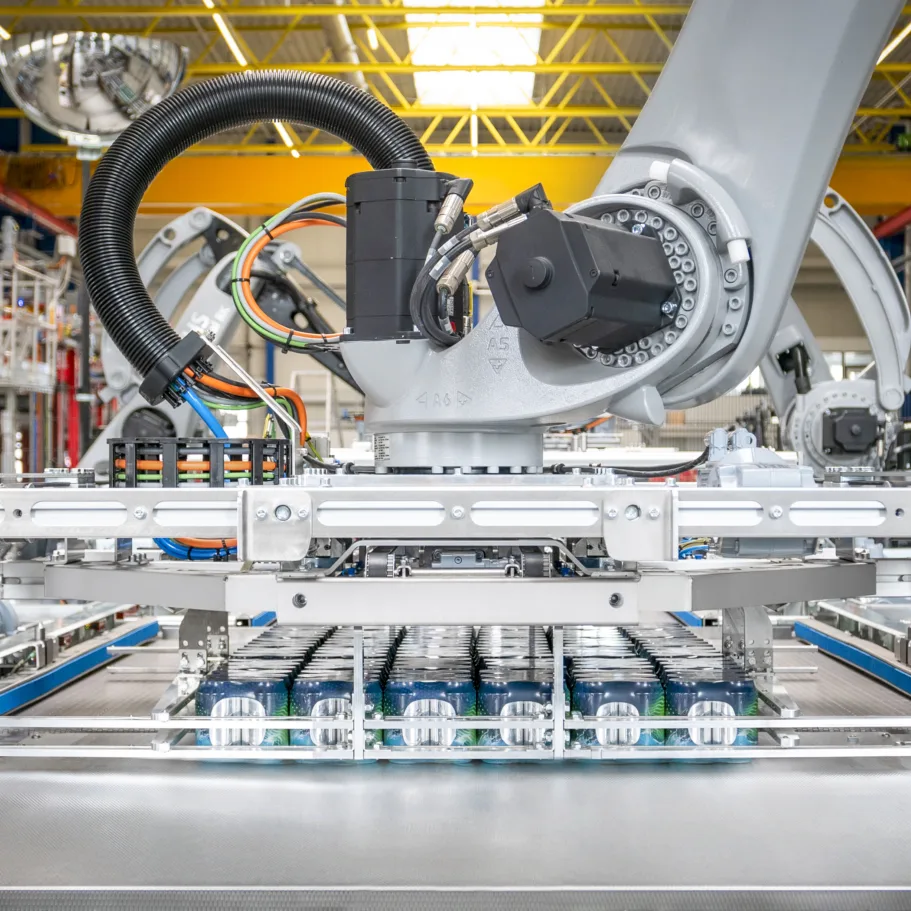

KHS has also been investigating the use of recyclate for some time now, namely since 2012. The experts in its Bottles and Shapes™ service program focus on the practical application thereof on their stretch blow molders and all of the filling and packaging lines engineered by the Dortmund systems supplier. “We run tests to qualify recycled PET so that we can tell our customers in advance which impact the material will have on the blow molder and bottle quality,” says Arne Wiese, product manager for Bottles & Shapes™ at KHS Corpoplast. “Our aim is to be able to quantify the various different qualities.” In doing so, KHS must of course work closely with preform manufacturers. They are ultimately often the companies which subject the washed PET flakes or rPET granulate to further thermomechanical processing and prepare them for injection molding. “We’re consulting with all of the major plastics processors in Europe on this topic,” Wiese emphasizes. And that’s not all; KHS is also cooperating with various engineering companies on preform manufacture. One result of such partnerships with injection molding machine manufacturers, for example, is that data from the injection molding process can be used just in time to adapt the stretch blow molding process. This makes bottle production faster and more efficient and improves the quality of the finished containers.

»We provide many sustainable and effective answers to the challenges thrown up by the current packaging debate.«

Head of Technology at KHS Corpoplast

Adaptations required

“With recyclate the color can vary from batch to batch, for instance,” is how Wiese outlines one of the challenges faced. “Darker material absorbs heat better. The lower heating capacity requires less energy. This makes production more efficient yet means that adaptations must be made to the blow molding program on the stretch blow molder. It’s therefore essential that the effects are quantified.” Another challenge is the intrinsic viscosity. “The longer the recyclate is boiled under vacuum, the longer the polymer chains become. This means that the intrinsic viscosity increases and the quality improves. However, this results in additional costs which not everyone is prepared to invest,” Wiese adds restrictively. “Here, we have to come up with ways of redistributing the material from uncritical areas – the bottle base in the case of still water – to more critical zones.” Experience shows that manufacturers of premium brands – whose containers have thicker walls – have less cause for adjustment than discounters, where all of the lightweighting options have often been exhausted. This is where recyclate can reach its limits.

In this context a technology developed by KHS in cooperation with inspection technology manufacturer Agr International scores points: Unit Mold Control, a digital, automated control system which regulates the blow stations on the InnoPET Blomax individually. It helps to control material distribution more precisely, reduces variations in the wall thickness by up to 30% and lessens any fluctuations in quality during stretch blow molding. “This is especially relevant when using recycled PET,” explains Frank Haesendonckx, head of Technology at KHS Corpoplast. “Here, the quality of the material can vary, meaning that the lower the preform weight, the greater the fluctuations in material in the bottle and the more unstable it becomes.” During continuous wall thickness inspection the new system identifies any unwanted material displacement and automatically counteracts this, states Haesendonckx. “Unit Mold Control combines weight reduction with bottle stability and is thus one of the many sustainable and effective answers KHS has to meet the challenges thrown up by the current packaging debate.”

According to Bottles & Shapes™ expert Arne Wiese there are no convincing arguments against the use of recycled PET in beverage bottles. The only relevant difference he sees between virgin PET and recycled material is the slightly darker color. This is a question of sorting, however – and only really visible in water bottles. With other beverages, such as the Beyond Juice bottle developed by KHS which is made entirely of recyclate, the consumer wouldn’t even notice the difference once the bottle is filled. As far as the mechanics are concerned, there’s nothing to stop companies converting to rPET, providing ideal conditions for the creation of a functioning circular economy.