Performance instead of downtime

KHS has consistently further developed the sequential overhaul of filling valves, also known as rolling maintenance. This means that customers can significantly reduce the downtime of their fillers, work more flexibly, and permanently increase the availability of their systems.

The sequential overhaul of filling valves is based on a simple but effective principle, which translates directly into measurable benefits for the customer. “Our fillers are equipped with 125 filling valves on average, depending on the container category and machine type,” explains Torben Brill, Service product manager at KHS. “To overhaul all the valves in the traditional way, two employees need up to two weeks. That is the time the filler must be shut down for in order to perform this time-consuming full overhaul. However, for the sequential overhaul of filling valves, at plannable intervals only as many fill-ing valves are removed at once as there are in a replacement set. Typically, that means 20 valves that can be changed in just two hours.”

Mobile workshop

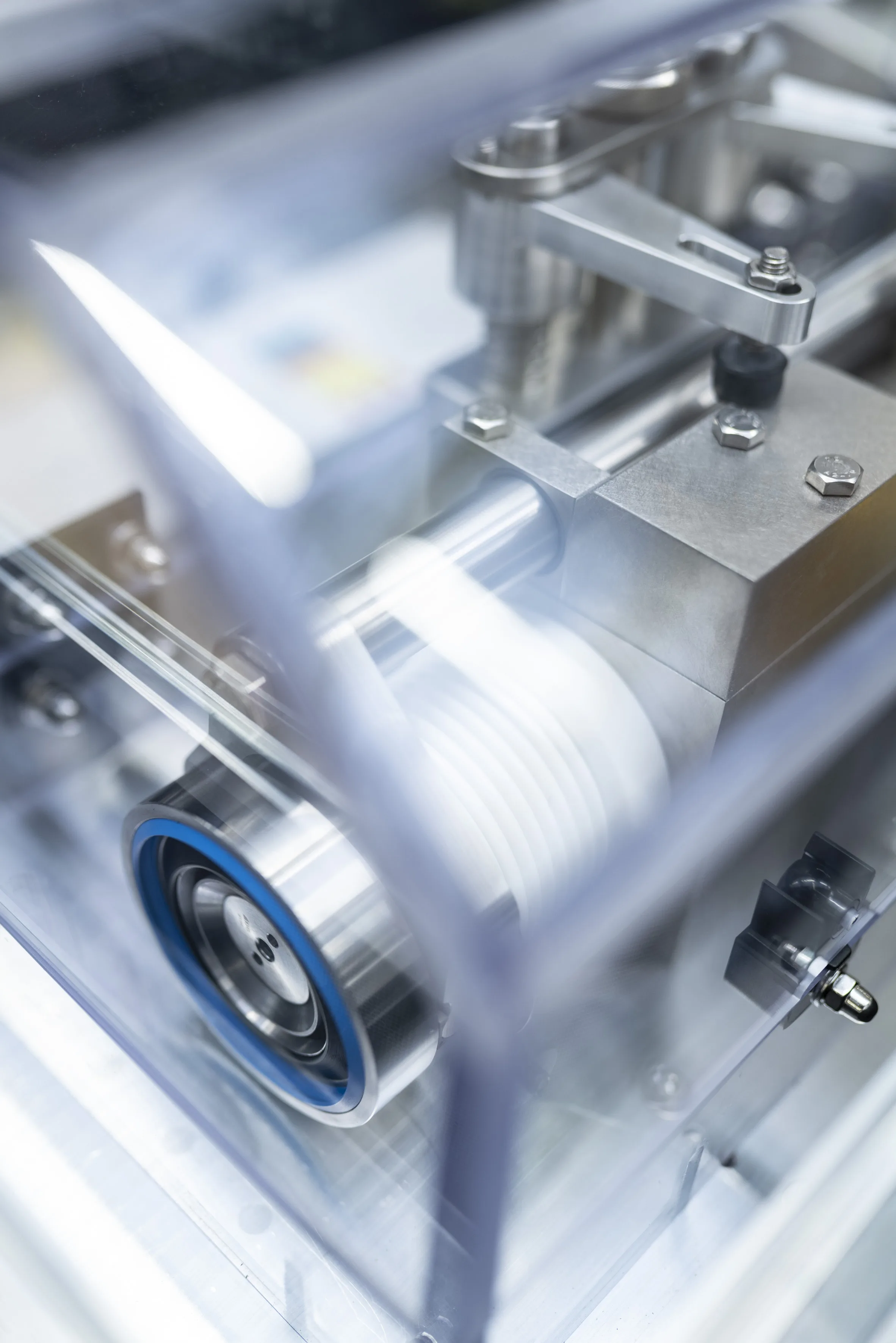

For sequential overhaul, KHS takes the workshop directly to the customer, as it were; with a mobile test and overhaul station in the form of a case, all work can be carried out on site. Here, valves are overhauled and tested for leaks. Once they have been replaced, the filler can be put straight back into operation. That reduces the error rate on startup to under 1%, and downtime from around two weeks to about ten hours in total. “It ensures that production can start again more quickly and with quality that has been tested,” summarizes Torben Brill.

“We think it’s important to not only provide our customers with a technical upgrade, but also to make their day-to-day production work noticeably easier.”

Service product manager at KHS

Advanced HMI and flexible tests

To make this process even more efficient and flexible for beverage bottlers, KHS has specifically improved the technology that is used. An advanced HMI now lets you choose between different test procedures, and a new adapter plate decouples the filling valve from the base plate. This means a single kit can be used for different types of filling valve – a major benefit for production sites with several types of filler. For customers, that means less equipment, shorter maintenance cycles, and valve quality that has been tested before installation. Torben Brill emphasizes that “KHS is continuously developing its products further, always taking specific customer requirements into account.” “We think it’s important to not only provide our customers with a technical upgrade, but also to make their day-to-day production work noticeably easier.”

Further development of the sequential overhaul of filling valves means a single kit can be used for different types of filling valve – a major benefit for production sites with several types of filler.

Suitable for all valve types: a new adapter plate decouples the filling valve from the base plate of the test device.

Service made to measure

Beverage bottlers decide whether to carry out the process themselves or have KHS personnel do so. The all-inclusive, trouble-free package contains everything needed for one year – measuring devices, an automatic testing facility, spare and wear parts such as sealing rings and easy-to-understand installation and operating instructions.

The service is available as part of a multi-year contract, with the kit provided to the customer on loan free of charge. Prior to every assignment, KHS service specifically checks whether the customer's filling valves are suitable for the process, thereby ensuring optimum application.