With passion

In After Sales and Service in Zinacantepec project and customer orientation are just as vital as thinking outside the box. It’s therefore hardly surprising that training is becoming increasingly important in this field of business.

When Michael Steggemann took on responsibility for After Sales and Service at KHS for Mexico, Central America and the Caribbean six years ago, the team was still extremely rigid in its structure. “Besides one service manager, at the time there were then only 15 service engineers,” he remembers. “And they faced the challenge of having to have a basic knowledge of all KHS machines and customers. This was practically impossible to achieve.” Steggemann’s first measure was therefore to set up a matrix organization which both aimed to improve customer satisfaction and focus more strongly on projects. This necessitated a more intensive exchange between Service and Project Management, Production and Sales on a joint communication basis in order to create synergies and make processes more efficient.

Maximum customer orientation

The most significant step taken to achieve even greater customer orientation was to assign five area inspectors who then actively split the enormous region up between them. The main deciding factor behind the operation was that every customer should be able to be physically reached within two hours – an extremely ambitious goal considering the infrastructure and vast size of Mexico alone. “We’ve greatly improved customer contact with the introduction of this new role,” explains Steggemann. “Our area inspectors know their contacts, their potential and their requirements down to the last detail. Our customers find it important that we don’t simply repair single machines. Often this isn’t enough to enable them to continue production. Our service team examines the entire line and can offer turnkey solutions which either prevent production downtime entirely or cut it down to a minimum.”

»We constantly analyze the equipment on site and evaluate its efficiency and quality.«

Area Inspector, KHS Mexico

Alberto Sanchez is one such area inspector. The 50-year-old has been a member of the KHS team in Zinacantepec for twelve years and is now responsible for the north of Mexico. He makes about 100 customer visits per year, flying distances of up to 4,000 kilometers in the process. “Our customers know that we work together with them as partners to find solutions for their filling lines,” he says. “And these are as diverse as our local installed base.” Sanchez knows what he’s talking about: of the approximately 950 machines up and running in Mexico, about a third are over 25 years old. These require a relatively high number of spare parts yet as they grow older – despite the almost legendary long service life of KHS plant engineering – so too does the risk of a veteran machine failing completely and a new investment becoming necessary.

Sanchez’ tasks include not only ensuring smooth operation at his customers’ plants but also providing regular feedback to KHS Sales. In the wake of growing project orientation the area inspector no longer simply functions as a communicator and recorder of information but is also partly responsible for generating turnover – in other words, he also takes on a service manager function. There are regular review meetings, at which the figures from the separate regions are scrutinized in a white spot analysis, for example. “We plan our activities on the basis of these findings and make our partners offers according to demand,” is how Alberto Sanchez sums up the process.

Service provided by KHS scores on project and customer orientation by focusing on the entire line and supplying turnkey systems.

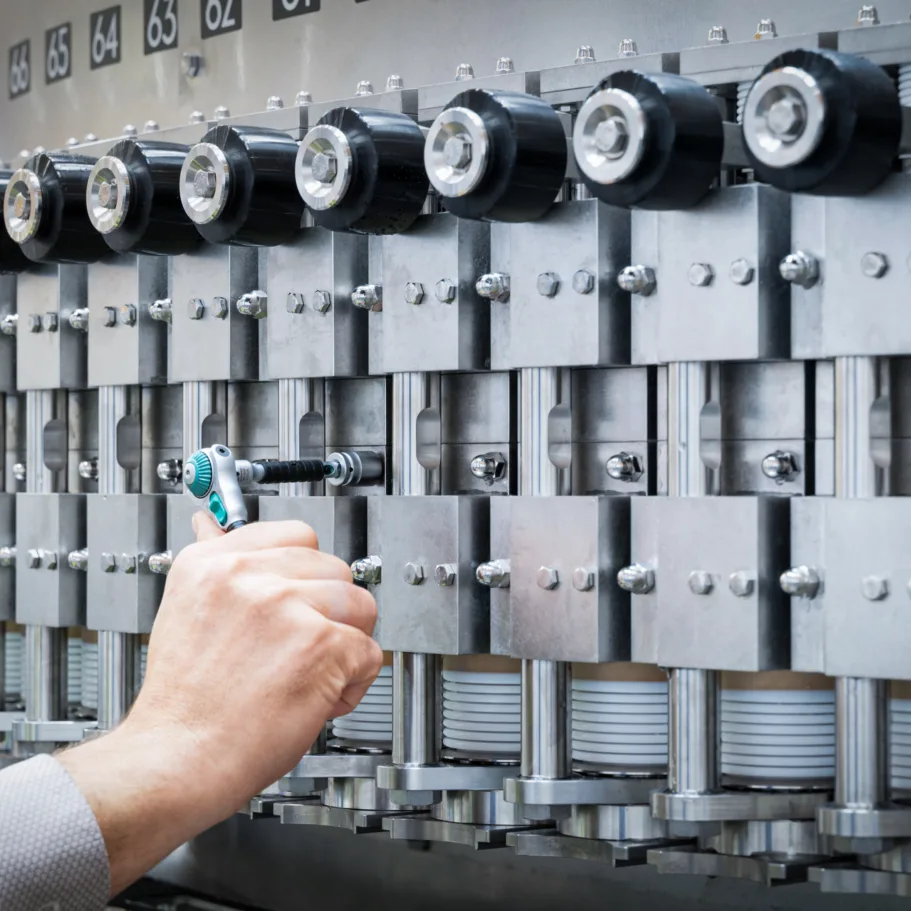

Focus on conversions

The service business in Mexico and the region goes far beyond simply providing spare parts and repairs. Because of the constellation of the installed base, conversions also play a major role. An old glass filler may need switching over to PET, for instance. Another example is the recent replacement of filling valves and return air tubes on a system used by Coca-Cola. “This wasn’t the first upgrade we’ve provided for this customer,” reports Sanchez. “We constantly analyze the equipment on site and on the basis of machine states and performance data such as efficiency and quality identify which parts need to be improved or replaced.” With its new valves Coca-Cola now bottles at a 25% higher filling speed.

The situation in the region is one of extremely rapid change. “The beverage industry here is developing from a locally oriented market with lots of family businesses, many of them very large, to a multinational business,” ascertains Michael Steggemann. “Spare part and service contracts with global concerns and key accounts now go through the KHS headquarters in Dortmund. While the classic service business is on the decline, we’re having increasing success with customer training courses and coaching sessions.” Service manager Lourdes Sanchez is responsible for this area. She’s worked for KHS Service for nine years and coordinates all assignments carried out by the 35 engineers on the team. One current example of a larger training project is the new Heineken site in Meoqui. “We first chose engineers with the necessary specialist knowledge, experience and appropriate language skills,” states Sanchez. The four engineers selected were given initial theory lessons in Mexico before taking part in tandem training courses worldwide and completing the KHS certification process.

Only satisfied employees are also loyal employees: this is why at KHS plenty of time is taken to select and train the right colleagues, giving them tasks and responsibilities they can identify with.

Successful training

They took just seven months to do so; the usual time span is a year. “This was of course quite a challenge when it came to coordinating the availability of our engineers,” the service manager reminisces. “The support provided by our colleagues in the Training Department was naturally a great help.” The result of these endeavors are four certified new machine instructors specialized in packaging, conveying, filling and pasteurization who not only train up customer engineers but also KHS service engineers throughout the whole of Latin America.

»The support provided by our colleagues in the Training Department was naturally a great help.«

Service manager for KHS Mexico

With a simple calculation Steggemann demonstrates that training is a promising business model. “If a beverage concern that employs 350 service engineers with a relatively high training requirement has a fluctuation of just 10%, this means that 35 new engineers have to be trained every single year.”

In-house training also has high priority at KHS Mexico: as part of an intensive management training program of the organization’s personnel skills in project and spare parts management and engineering have been taught since 2016 – partly by simulating specific practical projects. In terms of project orientation and customer satisfaction training on line optimization has also been given since 2018 to heighten employees’ awareness of holistic systems. In view of this investment in his team Steggemann is pleased that there’s very little fluctuation at KHS in Mexico. “We spend a lot of time choosing the right people and training and developing them in all of the relevant areas. At the same time we attach the utmost importance to our employees having tasks and responsibilities which are important to them and match their aptitudes and skills. After all, only satisfied employees are also loyal employees.” Conversely, applicants in the traditionally very family-oriented country of Mexico find job security just as important as the perspectives offered by an international company – two demands which KHS satisfies exceptionally well.