Slim line

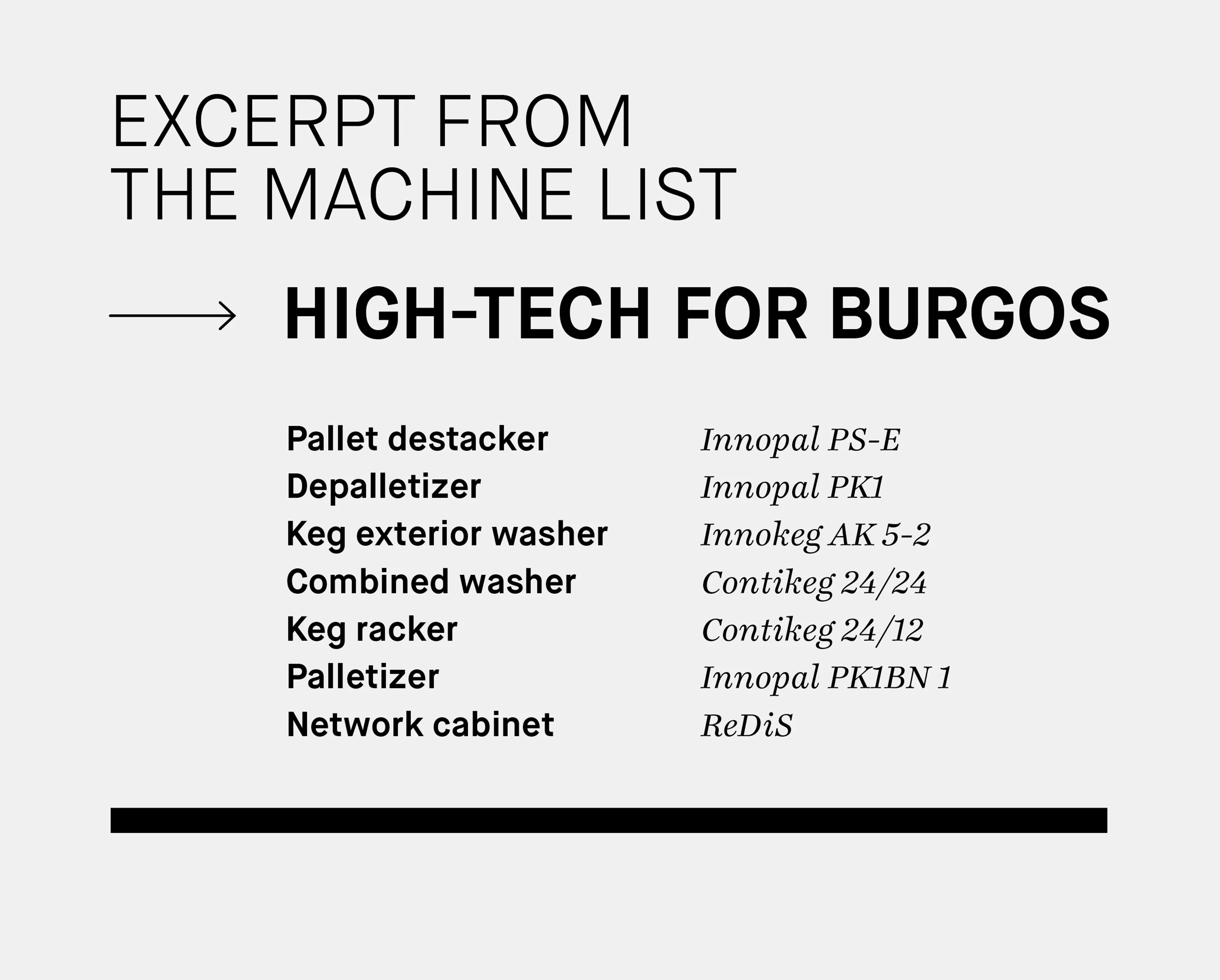

The new keg line in Burgos was to take up as little space as possible but be packed with plenty of high-tech to satisfy the brewery’s demands for quality, flexibility, ecology and economy. It was also to be able to easily double its capacity as required. KHS has made all this possible.The new keg line in Burgos was to take up as little space as possible but be packed with plenty of high-tech to satisfy the brewery’s demands for quality, flexibility, ecology and economy. It was also to be able to easily double its capacity as required. KHS has made all this possible.

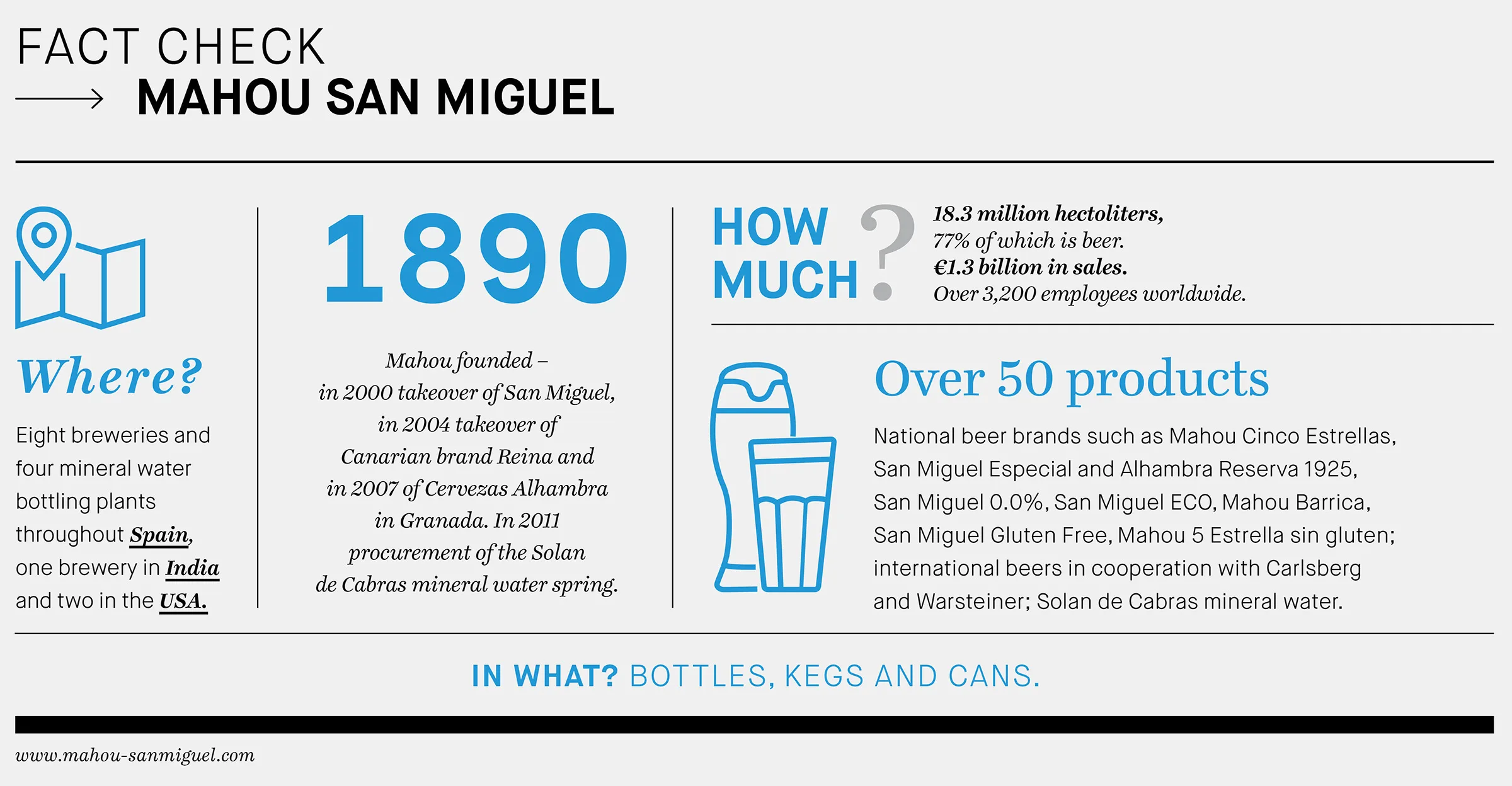

Mahou San Miguel looks back on a long tradition. One of the two predecessor companies started out in Madrid as Hijos de Casimiro Mahou in 1890. The beer it produced and sold under the Mahou label quickly became popular throughout the entire country. The factory opened in 1993 in Alovera to the northeast of Madrid is still the biggest brewery in Europe. The second founding company also dates back to 1890. In this year a Spaniard established the very first brewery in Southeast Asia with San Miguel in the Philippine capital of Manila. He soon began exporting his beers to Shanghai, Hong Kong and Guam. Other facilities gradually opened, first in Asia and then for the first time also in Spain in 1957. The European subsidiary soon became a company in its own right. San Miguel is now one of the world’s top ten brands of beer. When it procured San Miguel in 2000, Mahou ultimately became the largest brewery group in Spain. At the time of writing it brews over 70% of all Spanish beer drunk worldwide and is active in more than 70 countries. On the home market the family business is market leader with a share of 34%. In 2011 Mahou San Miguel expanded its portfolio to include mineral waters and soft drinks whose percentage of the total sales is steadily growing.

»KHS’ expertise and practiced routine give us great added value, especially with our keg projects.«

Operations development director at Mahou San Miguel

Long-term business relationship

The brewery’s relations with Dortmund systems supplier KHS, which itself has a history dating back over 150 years, also enjoy a long tradition. “I don’t know the exact date when our companies first made contact,” admits Javier Carballo, operations development director at Mahou San Miguel. “However, I do know that we’ve been working together for several decades. Much of our plant engineering is from KHS – from craters and decraters through bottle washing and filling machines, tunnel pasteurizers and Kisters packaging machines to one of the first compact canning systems for the low capacity range.” In the past few years this cooperation has grown considerably stronger. “In many of our projects we’ve invested in machines which cover practically the entire KHS product range.”

It thus goes without saying that this long-term, extensive cooperation has resulted in a real partnership being built up. “Our business relationship is marked by mutual trust,” explains Miguel Pastor, managing director of KHS Spain. “Besides the quality of our products and our reliability Mahou San Miguel especially appreciates our cooperation as regards the engineering. In particular this includes the design of the line layout which we developed together with the customer’s own engineers.” Javier Carballo confirms this and adds, “The teamwork between our two companies is perfect. We also mustn’t forget KHS’ expertise and practiced routine which give us great added value, especially with our keg projects.” The Dortmund company indeed now has over 40 years of experience in this segment. By constantly developing the required technology they provide optimum process cycles for returnable and non-returnable containers.

Miguel Pastor (managing director of KHS Spain), Carmen Germann (head of Regional Center Southern Europe, KHS GmbH), Javier Carballo (operations development director, Mahou San Miguel) and José Miguel Fernández Fernández (filling and packaging engineering manager, Mahou San Miguel).

Scores on its principle of continuous carousel operation: the Contikeg system is based on a rotary washing and racking machine coupled with a high capacity.

Line with growth potential

This expertise was one of the reasons for KHS also being awarded the contract for the new turnkey kegging line at the production site in Burgos in northern Spain. The specific technical challenge here was to plan a line to fit into a small space which at the first phase could output up to 500 kegs an hour yet could also be increased to twice this capacity if and when required. “Our approach to this project was to design a line which could be scaled from 500 to a maximum of 1,000 kegs per hour, with which we could cover our current capacities but which also factors in future expansion,” states Javier Carballo. “Because kegs are the most sustainable containers for Mahou San Miguel we’re determined to continue to increase their share of the total output in the future.”

KHS and Mahou San Miguel have given the brewery’s future plans for expansion the room they need with a mutually conceived line layout. “We planned a line which can double the capacity of the first phase by simply adding a second rotary racker – in other words, a single machine,” Miguel Pastor tells us. Javier Carballo nods in agreement and says, “In all our deliberations, from the very beginning we also thought about how we could create as perfect a working environment as possible with respect to operation and maintenance but also tidiness and cleanliness. KHS’ experience in the day-to-day operation of kegging systems made this a lot easier – as did the fact that we only had to deal with a single contact for practically all sections of the line. This cut any loss in communication and friction down to an absolute minimum.”

Mahou San Miguel also had very specific requirements regarding flexibility. The line should be able to process kegs of various sizes and with different types of fitting. At the same time format changeovers were to be as fast as possible and at best no adjustments be required after setup in order to achieve maximum line performance. The brewery’s specifications concerning occupational work and safety, product quality assurance and ecological and economic sustainability were also very high.

Clean, efficient and sustainable

With its Innokeg Contikeg, a rotary keg washer and racker with a high capacity distinguished especially by its hygienic design, KHS was able to convince its customer on several counts. Up to 1,000 kegs per hour ranging in size from 10 to 50 liters can be run through pre-washing and main washing cycles and racked fully automatically on a uniform platform. Sophisticated safety checks and efficient fault and rejection logistics ensure optimum product quality which encompasses both the microbiological safety and quality of the beer. Innokeg Contikeg technology also has ambitious standards regarding sustainability. By using water cascades large amounts of water can be saved during washing; the patented KHS Direct Flow Control system also reduces CO2 consumption during racking by up to 40%.

Javier Carballo is pleased with the savings in resources made in conjunction with his new line. “Even if it’s still too early to quote concrete figures, everything suggests that we’ve been able to considerably lower our energy and media consumption compared to the existing line.” He’s also extremely satisfied with the system’s productivity. “As we’d hoped, the level of efficiency is very high – even though our operating personnel haven’t yet fully completed the learning curve.”

Enjoying increasing popularity in Spain especially: the 20-liter slim keg.

Flexible for slim formats

The new keg line even gives Mahou San Miguel the flexibility they want. The line is able to process what are known as slim kegs containing 10 or 20 liters of beer which are rated highly particularly in Spain. “The line allows us to respond to our customers’ needs,” says Javier Carballo.

Plenty of room for expansion: by adding just one single machine the line can double its capacity. In the foreground: the keg exterior washer.

In addition to the high quality of the technology, the level of after-sales service is also a major criterion for the Spanish brewery when considering an investment. Javier Carballo attaches great importance to two aspects in particular. “Firstly, for us the support provided by remote diagnosis is essential. This of course requires that our network security standards are upheld which demands a great degree of flexibility. Secondly, the spare parts availability and logistics are also very important to us as they enable us to reduce our warehouse stock accordingly. The situation has become much better here but there’s still room for further improvement.”

To conclude, Javier Carballo finds that the biggest challenge in the coming years will be to continue to drive sustainability, flexibility for small batches, digitalization and ergonomics. The top priority, however, is not to endanger the outstanding quality and productivity which has already been achieved.