Out of thin air

In our interview Climeworks CCO Daniel Egger explains how the Swiss company is filtering CO2 from the atmosphere and in doing so trying to stop climate change. This concept, both simple and pioneering, is increasingly capturing the attention of global brands, prominent investors and politicians.

Mr. Egger, with direct air capture Climeworks has developed a revolutionary technology that removes carbon dioxide from the ambient air. How does this work and which (waste) products are generated in the process?

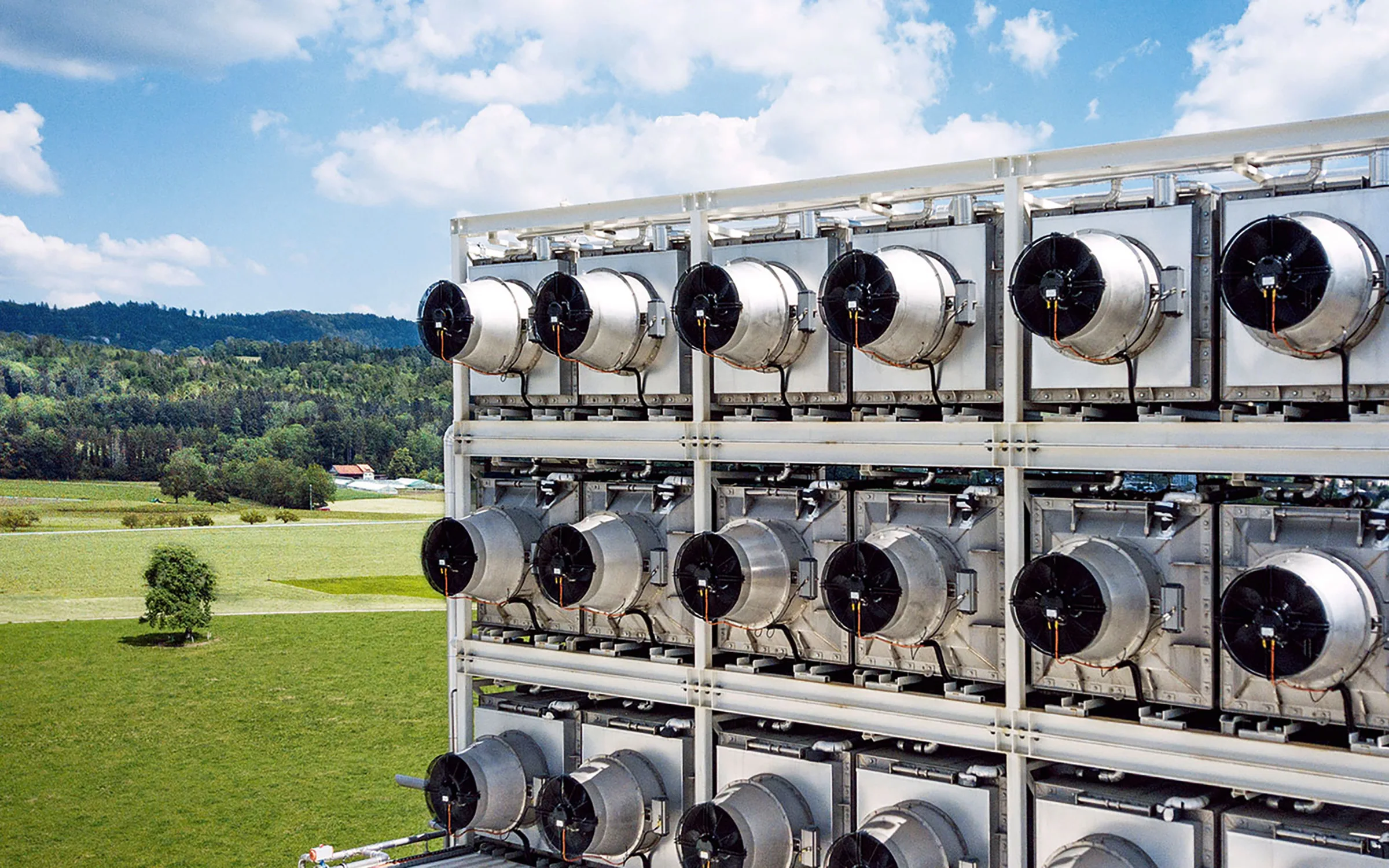

At the heart of our technology is a filter module encased in a metal box with sides two meters long. This contains an alkaline filter material that selectively removes acidic CO2 from the atmosphere and with it forms a weak chemical compound. Once the filter has been saturated, this can be released by heating it. We can regulate the process so that only CO2 is filtered from the air. Besides small amounts of pure water that can be reused, no waste products are generated. The carbon formed by filtering is the universal chemical building material. You need it to make plastics and fuels or as a basic chemical for further processing. CO2 is also used in food processing, for example in beverages, or in the form of fertilizer for greenhouses. You can even make diamonds out of it.

What form is the CO2 in once you’ve filtered it from the air?

It’s gaseous with a temperature of about 20 to 25°C at atmospheric pressure. From one of our plants it’s pumped through a pipeline into a greenhouse, for instance. Otherwise it’s cooled, liquefied and compressed for transportation. In Iceland, where we store CO2 in the basalt rock with our partner Carbfix, we add water to the gas to transport it. This forms a kind of highly-concentrated sparkling water that’s pumped several hundred meters into the ground. Here, it reacts with the volcanic rock to form calcium carbonate which you can imagine being like the white stripes in marble. In just two years the heat and special composition of the basalt rock cause the gas to turn to stone, a process that usually takes hundreds of thousands of years.

»An entire industry has to completely redevelop itself here, complete with suppliers and logistics.«

Chief Commercial Officer, Climeworks

How did the idea come about to filter CO2 from the air and put it to a different use?

This was originally a challenge at the ETH [technical university] in Zürich, in which synthetic fuels were to be manufactured in place of fossil fuels. When thinking about where the carbon needed for this should come from, people realized that the existing sources were only partly or not at all adequate for the scale required. You could of course use trees to make biofuel but there isn’t enough available material. The sole inexhaustible source of carbon is the CO2 in the air. This is what gave the two company founders, then both students at the ETH, their initial idea. Technologies that can do this have actually existed for a very long time; they were used in submarines and spaceships, for example, to reduce the concentration of CO2 in the air people breathed. But of course, in this field they don’t exist on the scale needed to solve the climate problem.

What were the special milestones achieved – and setbacks suffered – before coming this far?

If you’re in technical innovation and market development, you suffer setbacks every single day (laughs). But seriously, each step back encourages us to take two steps forward. One of the biggest milestones to date was undoubtedly the opening four years ago of our production site in Hinwil near Zürich, Switzerland, where for the first time we were able to demonstrate that direct air capture works on an industrial scale. A further important signal was the commissioning of the aforementioned first small plant in Iceland six months later. In October 2018 the Intergovernmental Panel on Climate Change published its special “Global warming of 1.5°C” report. This was a highlight of key importance to us, even if we weren’t directly involved: for the first time, this publication made it clear that our technology is needed. This greatly fueled interest and demand – and has enabled us to further develop our solution more quickly and provide it on a large scale. Finally, another very recent milestone was the successful commissioning of Orca last summer. With a capacity of 4,000 metric tons of CO2 per annum, our second plant in Iceland is the world’s largest climate protection plant to date.

On installing the first plant in Hinwil in Switzerland four years ago, Climeworks proved that the technology works on an industrial scale.

How do you get investors interested in such a pioneering idea?

When you develop a technology that has the potential to stop climate change, this is vision enough. After all, this is one of the biggest challenges the human race faces. Our investors believe in this and support us in our endeavors.

How realistic is it to assume that, in view of worldwide CO2 emissions of 37 billion tons a year, Climeworks can make a notable contribution to combating global warming with its method and business model?

Firstly, we have to drastically cut our emissions; there’s no getting round this. Unavoidable emissions that can’t be prevented for technical or other reasons can be catered for by a technology like direct air capture. The forecast is for a volume of between five and ten billion metric tons a year by 2050. This is a huge challenge that can only be met by an annual growth of 60% in our industry. If we compare this to wind power and its 30 to 35%, this is ambitious but not impossible. After all, we don’t need any materials or resources that would restrict us in any way or any basic new components, as was the case with photovoltaics. In this respect, direct air capture has the necessary degree of scalability.

Surely you have to share this mammoth task with your competitors.

Absolutely. Besides our main market competitor Carbon Engineering in Canada, there are a few other companies currently emerging in this sector – and they’re needed. An entire industry has to completely redevelop itself here, complete with suppliers and logistics – similar in proportion to today’s oil and gas industry. We also need regulatory provisions. This primarily entails taxing CO2 emissions at a rate of between €100 and €200 per ton so that carbon dioxide removal can be paid for. If this CO2 tax isn’t introduced, there won’t be any direct air capture and we won’t be able to stop climate change. At the moment, the regulatory environment is extremely dynamic: the Biden administration has declared direct air capture a key technology that is to be developed on a massive scale; the EU has included it in its strategy paper; and in Germany the latest PtL* roadmap states that CO2 must come from the air. The course is now being set.

* PtL roadmap = power-to-liquid roadmap. Plan by the German government to use at least 200,000 metric tons of electricity-based kerosene in German air traffic by 2030.

In the future, must our cities be filled with your filter modules to stop climate change?

There’s no reason to worry about this. Where our plants are sited depends on two factors. One: what are you going to do with the CO2? If you collected a million tons of the gas in Zürich, you’d have to send a 40-ton truck through the city every five minutes to cart it away. In densely populated areas, this isn’t a realistic proposition. Two: do you have enough renewable energy to power your plant? The advantage of our technology is that it isn’t location-specific. This means that we can look for the locations that give us the best conditions. And yes, it’s true that our plant in Hinwil is rather ‘overengineered’ (laughs). Our most recent Orca project looks a lot more attractive, however, and has even won a design award.

»We’re working every day to further develop our technology and improve its cost-effectiveness.«

Chief Commercial Officer, Climeworks

How successful are your efforts to expand your capacities and cut costs?

At the moment we’re focusing on reducing our technology costs. Another step is to exploit our economies of scale by building bigger plants that incur lower costs than small ones. And finally, we expect a positive effect from the previously mentioned growth of an industry, a specialized supplier industry, in particular – but this is definitely no longer in our hands. However, the further development of the technology and the improvement of its cost-effectiveness are major tasks that Climeworks engineers are working on every day in order to improve our product.

The CO2 you remove from the atmosphere is used in Switzerland by Coca-Cola in beverage filling, for example. Could you tell us a bit about your partnership here?

Coca-Cola HBC Switzerland has long been an extremely important partner to us. The company procures CO2 from our plant in Hinwil to carbonate its VALSER mineral water (see the box entitled “Refreshing tailwind”). As a global brand Coca-Cola is of course a customer whose renown shines down on us like a hallmark of quality. However, you have to have your processes and quality management firmly in hand in order to pass muster in the US beverage company’s certification process. We’ve learned a lot in this respect and this has helped us to develop further.

What happens to the CO2 when the consumer opens a bottle of VALSER?

It escapes into the air. The concept of first capturing something to then release it back into the atmosphere confounds a lot of people. But here you have to consider where the gas would otherwise come from. It’s usually of fossil origin – in the best case from purified industrial waste or auxiliary gases. In regions without carbon dioxide fossil fuels are burned to produce CO2. Our technology therefore cuts emissions in this context.

Which other cooperations have you entered into?

One prominent name is Microsoft. The company has set itself the target of compensating for all of its emissions produced either directly or by electrical consumption since it was founded in 1975 by 2050. In the first round of the program it explored 25 technologies, among them direct air capture. The aim is to cover its own requirement through purchasing agreements designed to cut costs more quickly. Microsoft taking a pioneering role in this field also inspires confidence among other companies and investors. Companies we already work closely together with include Stripe, Shopify and Audi, for instance. What’s more, we remove Bill Gates’ personal emissions from the atmosphere. And one of our many particularly brilliant stories comes from our customer Aether in the USA who turns our CO2 into synthetic diamonds.

Which other innovations are in the Climeworks pipeline and what can we expect from your company in the future?

Our clear focus will continue to be on direct air capture technology. Our prime aim is to boost our capacity so that we can build more, bigger plants. We’re also pursuing two sustainable fuel projects: one is the Zenid project at Rotterdam Airport where we want to make kerosene on site with various partners and for which we’ll remove all the elements we need from the air and use renewable sources of energy. The second is our partnership with European industrial consortium Norsk e-Fuel: here, renewable fuels are also being made, particularly for the aviation sector, with the help of our technology.

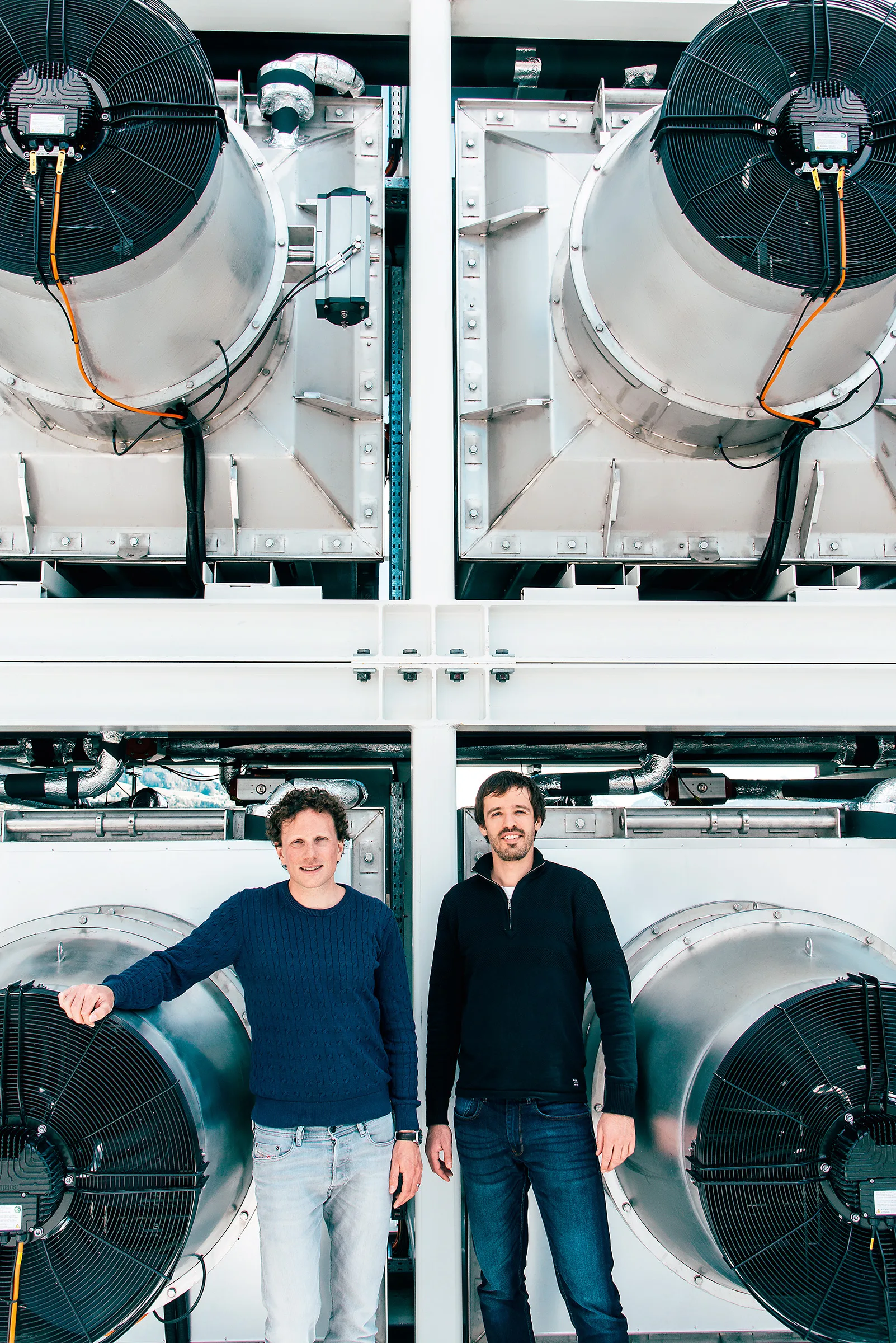

Climeworks founders Christoph Gebald (left) and Jan Wurzbacher in front of their direct air capture filter modules in Hinwil, Switzerland.

Ambitious target - Climeworks

As part of their mechanical engineering degrees and subsequent doctorates, Christoph Gebald and Jan Wurzbacher from Germany studied technologies designed to chemically and physically remove CO2 from ambient air on a laboratory scale. In November 2009 they founded Climeworks as a spin-off of the technical university (ETH) in Zürich. Today, the company is the world leader in direct air capture technology, with commercial plants in Switzerland and Iceland. Climeworks’ vision is to inspire a billion people to remove CO2 from the air.

CLIMEWORKS AND COCA‑COLA: Refreshing tailwind

In 2011 Patrick Wittweiler, country sustainability and QSE manager at Coca-Cola HBC Switzerland, first became aware of a then very new company called Climeworks. He was immediately captivated by the pioneering idea of direct air capture. He then tried to garner support within the Coca-Cola system for the notion of using CO2 captured from the air to carbonize beverages. This proved to be somewhat difficult, as the group makes extremely high demands of quality, especially regarding the ingredients used in its products.

When, many months later, the first samples were sent to company headquarters in Atlanta for CO2 analysis, the results were very promising. Subsequently, Coca-Cola HBC Switzerland didn’t itself become an investor but instead partnered Climeworks by publicizing its interest in the project with the authorities, investors and further potential clients. The response was positive and gave the founders a considerable boost.

Following the installation of the first commercial-scale direct air capture plant in Hinwil in 2017, business relations developed further. “The biggest challenge here was that a small startup with huge ambitions was facing an international concern,” Wittweiler remembers. “It was a meeting of two completely different cultures. For instance, Climeworks’ first draft of the contract was just three pages long, the final document over a hundred.” The first carbon dioxide extracted from the air was supplied in February 2019 to the bottling plant in Vals, with Climeworks’ climate-friendly direct air capture concept perfectly in tune with Coca-Cola’s clear strategy of sustainability.

In the meantime several 100 metric tons of CO2 filtered from the atmosphere have been filled into bottles together with VALSER mineral water. Great persistence was needed to convince all of the stakeholders in the company, Wittweiler states, but today he’s extremely proud of the fact that Coca-Cola HBC Switzerland was able to help give birth to a technology that everybody’s already talking about and will soon become a global trend – something the sustainability manager is totally convinced of.