High performance in series production

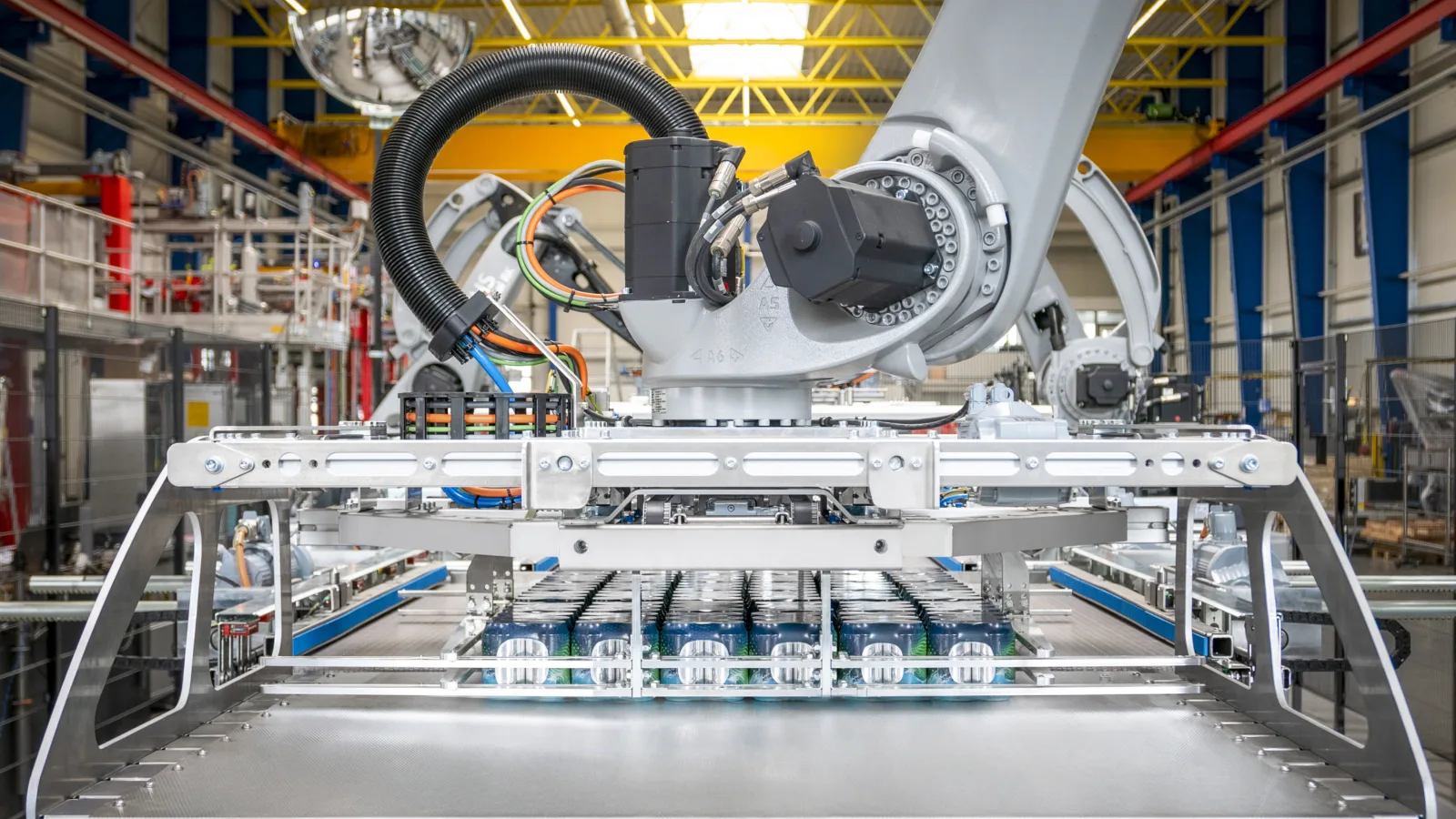

First introduced by KHS back in 2022, the Innopal PLR combines palletizing technology and robotics at the highest level. The high-performance palletizer has now been further developed and readied for serial production – with fully automatic format changeovers and efficient, safe and reliable pallet conveying.

Ralf Kretschmann, palletizing technology product manager at KHS, emphasizes how the market launch of the Innopal PLR was an important milestone for KHS: “The Innopal PLR is a first and a calling card for our palletizing technology. It is a high-capacity machine, combined with a low infeed and highly automated operation thanks to the use of robotics.” As a result, this smart system provides users with a wide range of benefits, especially in the areas of efficiency and automation but also with regard to occupational health and safety and ease of operation.

Expertise in palletizing and robotics

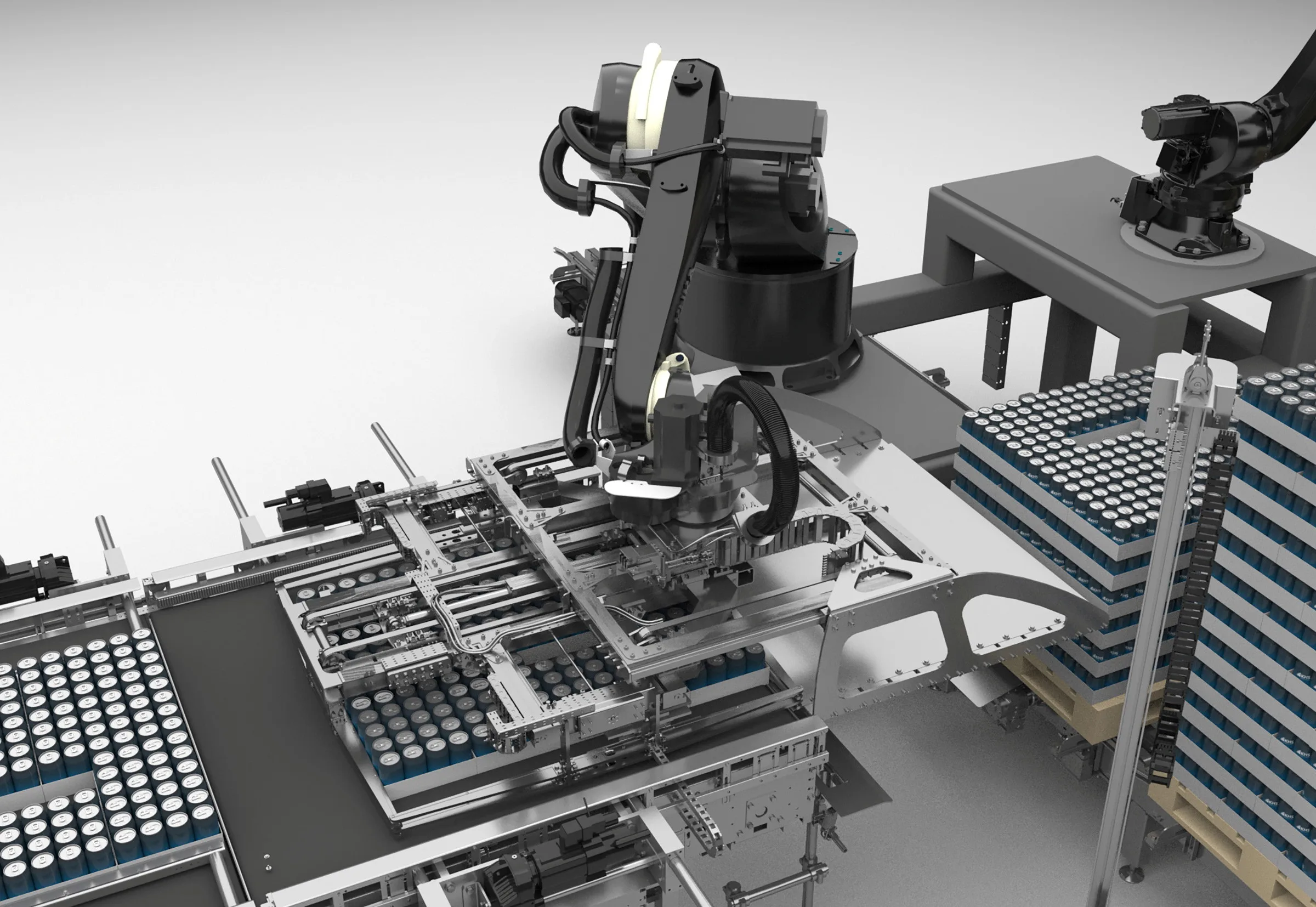

The Innopal PLR is satisfying the high global demand for robot systems in the palletizing sector. “Robots are still primarily found in the low capacity range,” explains Kretschmann. “We made a conscious decision to take a different approach with the Innopal PLR. It is designed to perfectly meet the requirements of customers in the high-capacity range as it is equipped with the latest generation of robots that can deliver a throughout of up to 650 layers per hour when processing PET bottles and cans. This means that customers can achieve line outputs of up to 240,000 containers per hour with one single palletizer.”

The Innopal PLR is designed to perfectly meet the requirements of customers in the high-capacity range as it is equipped with the latest generation of robots that can deliver a throughput of up to 650 layers per hour when processing PET bottles and cans.

The palletizer’s grouping system is equipped with a new option – the InnoPET iflex for fully automatic format changeovers. “The operator only has to choose the configuration on the HMI. The robots then select the right gripper themselves and change it,” says Kretschmann. This high level of automation has a positive effect on the efficiency, safety and speed of the format changeover process, while reducing the operator’s workload.

“The operator only has to choose the configuration on the HMI to carry out a format changeover. The robots then select the right gripper themselves and change it.”

Product Manager for Palletizing Technology at KHS

A unique combination

The Innopal PLR combines the benefits of an automatic high-performance palletizer with a low pack infeed. During development, KHS deliberately chose not to include a platform that is usually a standard feature in the high-capacity machine segment, and this offers clear advantages with respect to ease of operation and occupational health and safety.

The Dortmund engineering company also placed huge importance on safety when further developing the pallet conveyor – now called Innoline PTR Series II. “Among other things, we optimized and reduced all of the crushing and shearing points both on the conveying system itself and also in close proximity to the machine,” explains Kretschmann. “It was especially important to us that the Innopal PLR satisfies the highest requirements with regard to occupational health and safety. And as all of the conveyors in the new concept are frequency controlled, it is now possible to use enhanced diagnostics to ensure higher line availability.”

Comprehensive service from a one-stop shop

The line-compatible palletizer is also convincing with respect to versatility. It serves the three classic container segments of cans, PET and glass and can also handle all standard pallet formats. Furthermore, the robotics system is designed for durability and future security and is especially low maintenance.

This technical flexibility is supplemented by the comprehensive range of services offered by KHS – based on more than 30 years of experience in the use of robotics in the palletizing sector. The Dortmund systems supplier provides holistic support to its customers – from planning through installation and commissioning to maintenance and the supply of spare parts. KHS has developed its own tool especially for line design. “We understand the challenges faced by our customers,” explains Kretschmann. “Space is limited in the production shop and often restricted even further by columns and similar obstructions. Therefore, we have planned and pretested different layout variants for the Innopal PLR that fulfill almost all conceivable customer requirements.” The palletizing team also relies on the tried-and-tested 3D line design tool from KHS.

“We cover a large range of layout variants, performance requirements and processing programs with our customer-specific systems and solutions.”

Executive vice-president of the Packaging and Palletizing Product Division at KHS

High demand

The Innopal PLR has now firmly established itself on the market. It is in great demand, especially in Asia, Europe and North and South America. “We cover a large range of layout variants, performance requirements and processing programs with our customer-specific systems and solutions,” says Dr. Mohamed Astitouh, executive vice-president of the Packaging and Palletizing Product Division. “And this means we have achieved our goal: numerous optimizations have been made and fully integrated into the series production version of the Innopal PLR – just in time for drinktec.” KHS will be presenting the further-developed version of this pioneering high-performance palletizer for the first time at the trade show.