One more option

The new type of secondary packaging from KHS that wraps packs in paper instead of film can also be retrofitted on existing machines engineered by the Dortmund systems supplier. Customers can either opt for more flexibility – or permanently switch to paper.

Since 2020 KHS has provided a facility on its packaging machines for wrapping beverage cans in paper. In order to give customers maximum flexibility, the new function has been integrated into a combined machine that’s a real all-rounder: whether wrap-around packs, packs on trays or pads with or without film or paper wrappers, it can process a broad range of secondary packaging.

Paper may still be relatively new as a packaging material on the beverage market. As an alternative to plastic especially, however, this material is increasingly capturing beverage fillers’ interest. The paper wrapper meets consumer demand for alternative, environmentally-friendly packaging material. As not every beverage producer wishes to invest in a completely new machine, however, the ever more popular paper wrapping unit is now also available as a conversion option. This means that bottling companies can quickly react to marketing trends and consumer demands using existing Innopack Kisters packaging machines.

»Lots of bottlers want to keep all their options open for the future. For them the flexible combined machine is an extremely attractive proposition.«

Uwe Bartholemy

Head of Technical Support for Packaging, Service Division, KHS

Our short video has more about how our retrofit paper wrapping module works and which options are available.

Replacement or addition

KHS offers two retrofit alternatives beverage producers can choose from according to their specifications and requirements.

- If paper wrappers are to permanently replace shrink film as a secondary packaging, all that needs to be done is to substitute two modules; the machine layout can stay practically the same. Here, the former film wrapping module is replaced by the newly developed module that can process paper. The shrink tunnel is also substituted by a module that folds and glues the paper.

- Beverage fillers who don’t wish to compromise their flexibility when it comes to secondary packaging can choose the second option that enables the new paper packs to be produced alongside all previous types of packaging. In this case, the paper wrapping and paper folding and gluing modules are installed on the machine as an addition.

The folding and gluing module closes and glues the sides of the paper pack and can be integrated into existing packaging units with or without a shrink tunnel.

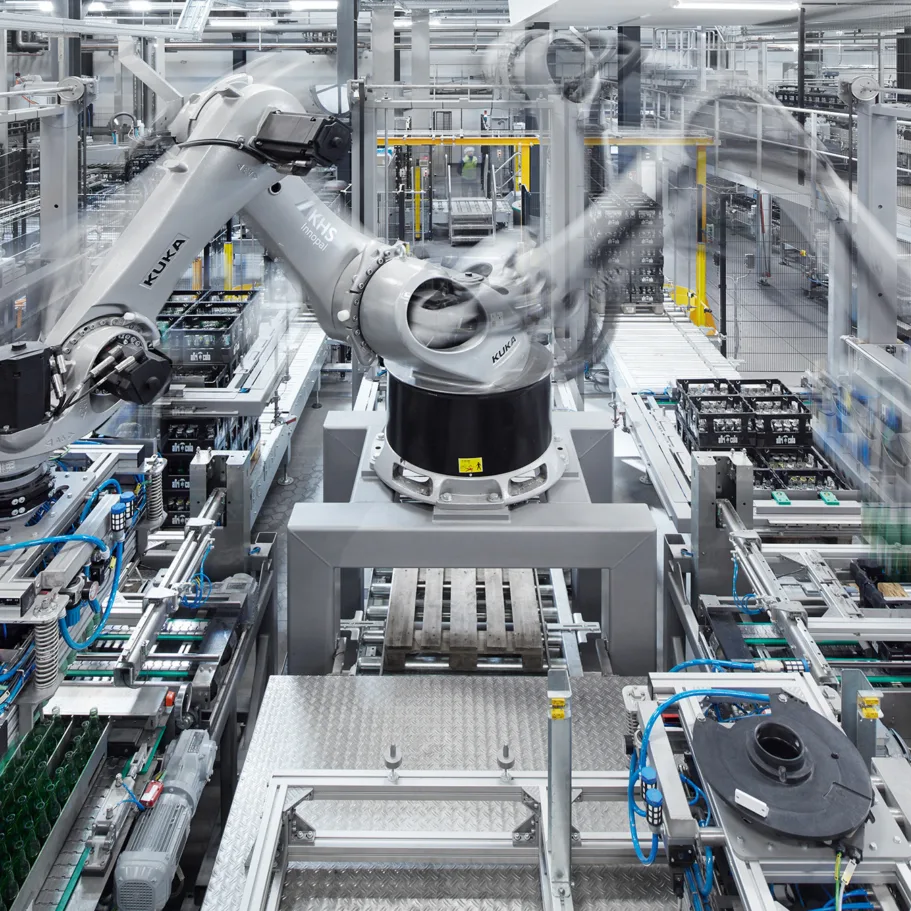

In the wrapping module the pack can either be encased in film or – as shown here – in paper.

Once the modules have been installed, switching materials calls for no other conversions except the standard format changeovers. As soon as the packaging materials have been changed over and the hot melt devices are ready for operation, production can begin.

“Conversion is a simple matter on all machine types in the Advanced series,” explains Uwe Bartholemy, head of Technical Support for Packaging at the KHS Service Division in Kleve. This is chiefly facilitated by the modular design of KHS Innopack Kisters machinery. Then a quantum leap for the industry on its launch in 2000, this plant engineering has long been adapted and established as a standard. “Generally speaking, we can also convert older machines in this way. Here, we carefully examine each individual case to check whether the control unit needs an update or not, for example.”

You can find more information about our multifunctional Innopack Kisters WSPP advanced packer on khs.com

Technically straightforward

From a technical viewpoint, on KHS Innopack Kisters packaging machines with a shrink tunnel only the existing film wrapping module has to be replaced by the further developed module for paper wrapping. This can then process both materials. Packers without a film wrapping module have the new module installed as an extension. As opposed to the former machine segment, this now also has a gluing station that sticks the paper together beneath the pack. The packers also require a paper folding and gluing module – either as an addition or a replacement of the shrink tunnel – where the packs are sealed.

The folding and gluing module closes and glues the sides of the paper pack and can be integrated into existing packaging units with or without a shrink tunnel.

Besides the obvious advantages of the new packaging system, the conversion service option in particular scores over investment in a completely new machine: the costs are much lower and only partial commissioning of the current formats is required as these have already been configured for the existing machine modules. Incidentally, when asked which of the two variants – replacement or addition – will be more in demand in the future, Bartholemy has a clear answer. “Paper wrappers are a relatively new form of secondary packaging and lots of bottlers want to keep all their options open with an eye to future market developments. I’m thus assuming that the flexible combined machine will prove an extremely attractive proposition for our customers.”

At a glance

Retrofit paper wrapping module

Applications

- Beverage and food cans (all sizes)

- Primary beverage carton packaging

- Other cylindrical and rectangular packaging styles

- Pre-packed products

Two variants

- Machine conversion to switch from film to paper wrappers as the secondary packaging: replacement of the film packaging modules and shrink tunnel by the paper wrapping and paper folding and gluing modules

- Retrofit to create a combined machine for flexible film and paper processing: replacement of the wrapping module and addition of the paper folding and gluing module

Benefits

- Low cost of investment

- Only partial commissioning of existing formats

- Faster resumption of production

Any further questions?

Uwe Bartholemy

Head of Technical Support - Packaging KHS GmbH, Kleve

+49 2821 503 - 246 uwe.bartholemy@khs.com