Future-proof packaging

... both in conjunction with packaging waste, which the beverage industry also produces, and regarding energy efficiency in production. The development of technology and engineering of lasting ecological and economical substance is becoming increasingly important. The following four examples prove that KHS is successfully applying itself to the corresponding tasks in a number of different ways.

Task 1:

USE LESS PET, GLASS AND TINPLATE

Bottles & Shapes™ combines quality with efficiency and sustainability.

Beverage packaging design isn’t just about successful sales and marketing. The KHS Bottles & Shapes™ service program effects a balance between market-oriented design, perfect line behavior and the efficient use of energy and materials – now also for glass bottles and beverage cans.

Task 2:

REDUCE ENERGY CONSUMPTION, USE MATERIALS MORE EFFECTIVELY

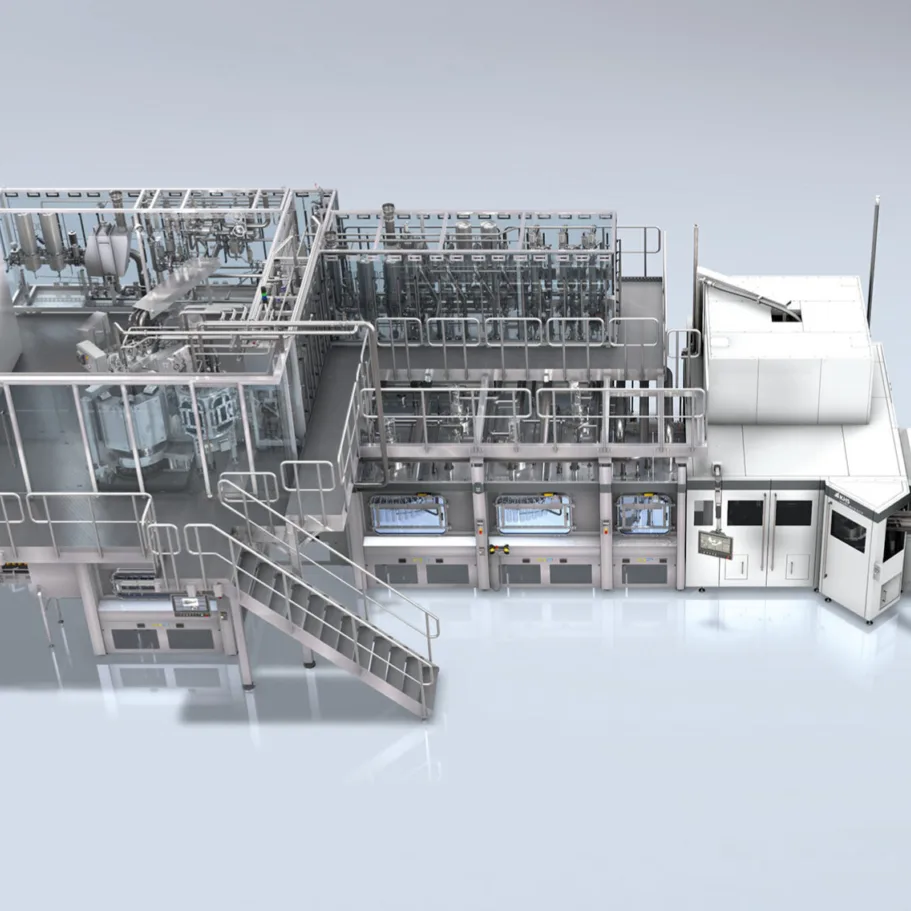

The InnoPET Blomax Series V – the new generation of stretch blow molding technology.

The new stretch blow molders from KHS aren’t just more powerful than their predecessors but also more sustainable and more efficient. Improved preform heating and a new cooling concept cut down on energy consumption; previously unstretched areas of PET can now also be used thanks to targeted heating and better material distribution.

Task 3:

ENSURE FULL RECYCLABILITY

FreshSafe PET® solves fruit juice beverage bottlers’ problems.

FreshSafe PET® is the only barrier coating for PET which – unlike most of the composite materials in use to date – can be completely segregated and fully recycled. With it beverage producers are best equipped to meet the ecopolitical challenges of the future and make more reusable recycling material available.

Task 4:

AVOID PACKAGING WASTE

Sustainable secondary packaging comes from KHS in Kleve.

In the battle against packaging waste KHS is actively helping to develop new standards. Its Nature MultiPack™ makes film packaging for multipacks completely redundant and tried-and-tested pack formats such as the FullyEnclosed FilmPack reduce the amount of cardboard needed to an absolute minimum.