Oops, I’ve shrunk the filler!

Markus Petkau has been a passionate technophile since childhood; an enthusiasm that originated with technical Lego for cars has now produced an almost fully functioning 1:20 scale model of a KHS filler.

Markus Petkau discovered his passion for building things as a little boy. His cousins encouraged this enthusiasm by supplying him with plenty of technical Lego; at the tender age of five, he was already constructing little cars that drove by themselves. His father also taught him practical technology by installing a drive in his Bobby Car, for instance. It’s thus no surprise, then, that when Petkau started high school, he already knew that he later wanted to pursue a technical career.

Technology and IT combined

While at senior high, he developed a fascination for software programming by studying YouTube videos. “I soon knew that I didn’t want to concentrate just on mechanical engineering or IT alone,” Petkau remembers. “Instead, by opting for electrical engineering, I went for something that combined the two.”

Not far from his home in the German state of Rhineland-Palatinate, KHS offers a dual work-study program in Bad Kreuznach that’s simply made for Petkau. It provides training as a mechatronics engineer alongside a degree course in electrical engineering.

“I initially only wanted my model to rotate but in time more and more specifications were added.”

Course developer and technical trainer, KHS

Passing on knowledge

As a course developer and technical trainer, the 28-year-old is himself now responsible for qualifying the next generation, charged with various tasks associated with the basic and further training of KHS engineers, particularly in filling. Here, he focuses on the electrics and electronics. He sees himself as an interface between the fields of design engineering, commissioning and training. Courses for employees and customers have taken him on many trips around Europe, plus to South America, Africa and New Zealand. He’s currently very much involved in the KHS Virtual Training Center project that facilitates playful learning, independent of the time and place, on digital machine models in a virtual environment.

Talking about play ... in his early twenties Petkau was still making model cars that achieved speeds of up to 90 kilometers per hour – all painstakingly built by hand. The necessary spare parts were provided by his own 3D printer – that he himself of course built from a kit.

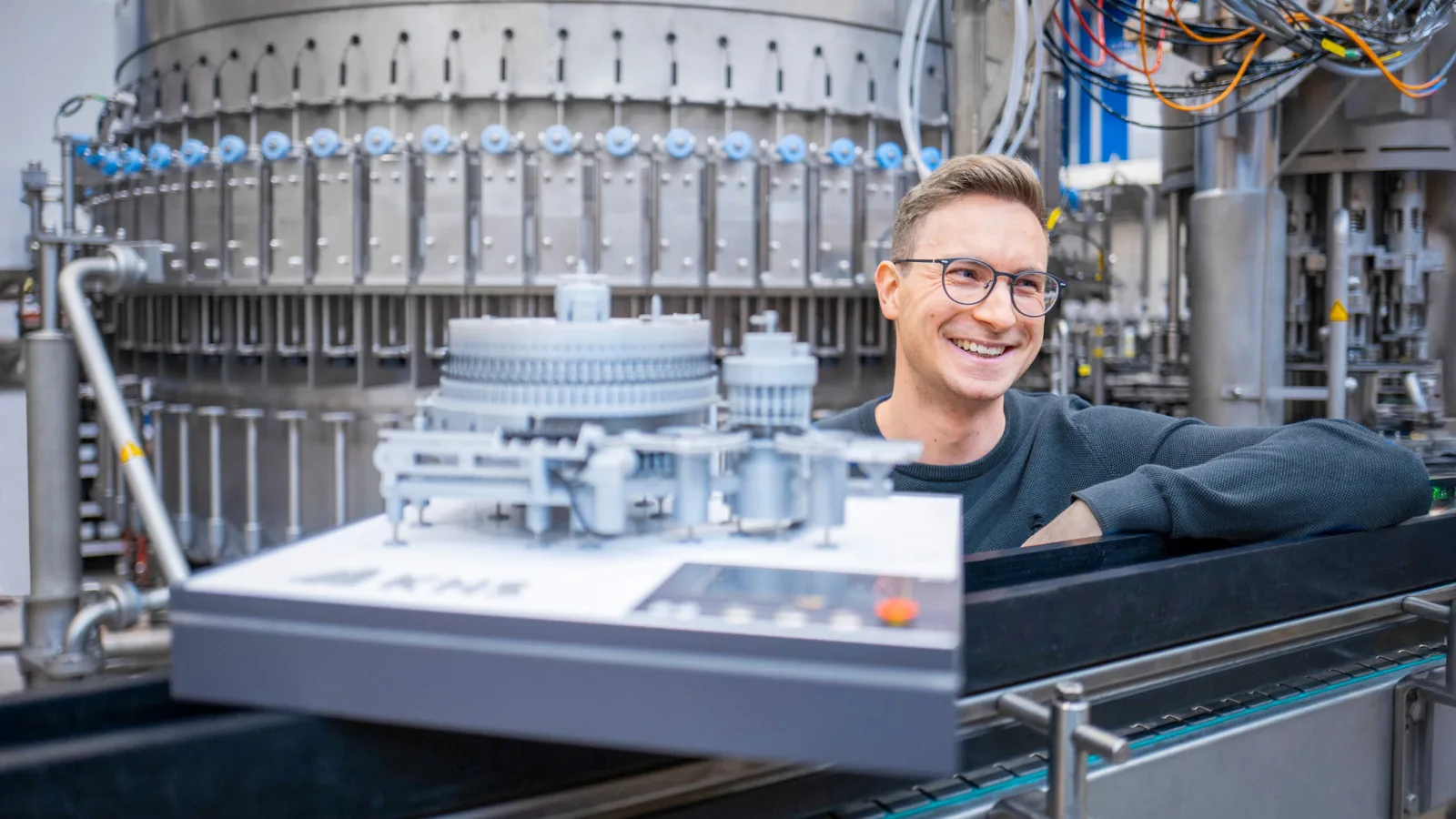

During the photoshoot in front of the original at the KHS factory in Bad Kreuznach, the modelmaker attracted plenty of attention from his colleagues.

In the production shop for the genuine KHS fillers, the small-scale model and fine detail of the individual parts are also a real eye-catcher for visitors.

Lengthy functional scale model project

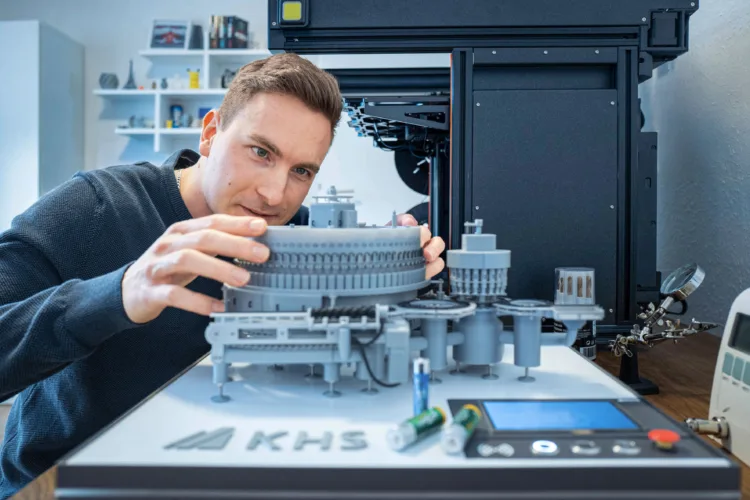

Petkau also came across scale modeling in his job: he was inspired early on, for instance, by a small, non-functional, stainless-steel model of a filler in his training unit. He wanted to do more, however, and soon began dreaming about building a working model on a scale of 1:20. “I started methodically developing my idea at the start of the corona pandemic in March 2020,” he remembers. “During lockdown, some people spent their sudden excess of free time watching TV series or gaming. I started to build a copy of our Innofill DRS ECO glass bottle filler. I initially only wanted it to rotate but in time more and more specifications were added.”

Growing challenge

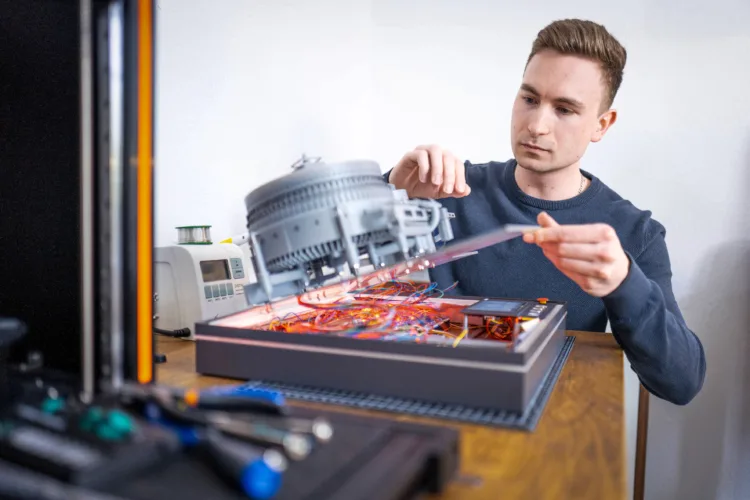

Petkau then began successively designing the gears, signals and control unit. He partly developed his own encoder cards that can’t be bought in the required miniature format. The model was even to have a functional HMI operator panel with a touchscreen. He’s especially proud of the automatic CIP caps. “Not all of the details are exactly true to the original but I still found a way of having them extend. Looking back, this was the most difficult part of the project.”

He finished planning within the space of a year, complete with prototypes and test runs. Petkau had to wait until the summer of 2024 to produce the final version, however; it took two-and-a-half years before the new high-tech 3D printer of the desired quality was finally delivered.

Dramatic setback

This wasn’t the only setback to try his patience: half way through the project, the main control unit blew – an extremely rare 3V controller +. Owing to the chip supply crisis, it was no longer available. “Back then, I thought ‘that’s it’,” the engineer says. After trawling shops and forums all over the world for months on end, a professor in Germany finally contacted him. He’d once used the chip at an observatory and was happy to pass it on to Petkau. Petkau now ‘only’ needed about 100 hours of printing time and two weeks for the final assembly of the model. The result is well worth seeing, as this YouTube video demonstrates.

The next challenge

His next project is already underway. This one will certainly be less complex: with the help of a WiFi-controlled IoT ground humidity sensor, Petkau wants to optimize his existing garden watering system to only supply water as and when needed. “Next summer will definitely be smart,” he laughs.