Lots to talk about

From September 15 to 19, 2025, the entire beverage industry met at the exhibition center in Munich, Germany, where at drinktec, the sector's leading international trade show, professionals from all over the world were looking for innovation and inspiration to help them make their businesses even more efficient and sustainable.

As at every drinktec, this year, too, Dortmund systems supplier KHS was one of the biggest exhibitors. As a key technology partner to the industry, the machine engineering company had a lot to show and tell guests at its booth in Hall B4. In this special drinktec issue of our web magazine, we’ve put together a number of interesting articles for you on KHS’ visit to the exhibition and the products, systems and services that were presented there.

The following are among the topics we’ll be focusing on:

- Filling and packaging systems for increased circularity with a lower TCO

- Holistic line solutions for greater efficiency and lower costs

- Digital systems and solutions for better performance and maximum IT/OT security

- Services to ensure that your production lines run for 25 years and longer.

MORE DRINKTEC-RELATED ARTICLES

Until October, check back here regularly for further articles on KHS's presence at the trade show.

NEW FUNCTIONS FOR LABELER

Impressive upgrades

KHS has equipped its tried-and-tested Innoket Neo Flex labeler with a new PSL station compatible with glass, PET and cans, a swivel-arm HMI panel and an optimized orientation system. In making these upgrades, the Dortmund systems supplier meets market requirements for greater flexibility and higher output.

To the article: Impressive upgrades

PRODUCTION LINE COACHING

Learning to read the line

New in the KHS service portfolio: intensive coaching on their filling line provides customers with a wealth of expert knowledge that goes way beyond the individual machines. With the in-depth understanding they then gain of the entire production environment, faults can be located and remedied more quickly and machine downtime avoided.

To the article: Learning to read the line

NEW BOTTLE-WASHING GENERATION

Make three wishes

KHS is catering for the requirements of the beverage industry with numerous optimizations: regarding resource conservation, space savings and ease of maintenance, the further-developed Innoclean Cascade D machine is setting new standards in bottle washing.

To the article: Make three wishes

SEQUENTIAL OVERHAUL OF FILLING VALVES

Performance instead of downtime

The mobile, sequential overhaul of filling valves by KHS reduces maintenance-related downtime from two weeks in the past to just ten hours – The mobile, sequential overhaul of filling valves by KHS reduc-es maintenance-related downtime from two weeks in the past to just ten hours - and thanks to specifically improved technology, beverage bottlers now benefit from even greater efficiency and more flexibility as a result.

To the article: Performance instead of downtime

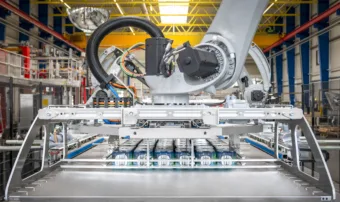

PALLETIZING

High performance in series production

First introduced by KHS back in 2022, the Innopal PLR combines palletizing technology and robotics at the highest level. This high-performance palletizer has now been further developed: it features fully automatic format changeovers and efficient, safe and reliable pallet conveying and has now been readied for serial production just in time for drinktec.

To the article: High performance in series production

SMARTCAN ECO BY KHS/FERRUM

Small. Smaller. Hygienic.

On the further-developed filler/seamer block, up to 93% less space for the hygiene zone, simultaneous interior and exterior cleaning and lots of other improvements make for even better hygiene, top quality and more efficiency and sustainability in can filling.

To the article: Small. Smaller. Hygienic.

INNOPET FRESHSAFE QUADBLOCK

Connect four

The new InnoPET FreshSafe QuadBlock sees KHS combine four functions for the first time: stretch blow molding, labeling, filling and coating with our successful Plasmax barrier protection. This ensures beverages with a longer shelf life and bottles that are fully recyclable, greater line efficiency and less space needed.

To the article: Connect four

KHS CAMPUS VIRTUAL

Successfully rolled out

Maximum flexibility, extensive learning options and gamification: the KHS Virtual Training Center offers courses on the majority of the current machine portfolio for cans, glass and PET – and is available in several different languages.

To the article: Successfully rolled out

ECOVADIS SUSTAINABILITY RATING

A platinum first

Following seven silvers and two golds, EcoVadis has now awarded KHS its first ever platinum medal. This places the Dortmund machine and systems manufacturer in the top one percent of the now over 150,000 companies assessed by the world’s leading provider of sustainability ratings.

To the article: A platinum first

DRINKTEC 2025

Expertise right down the line

At the KHS booth for drinktec, the world’s leading trade show for the beverage industry held in Munich, Germany, you can expect to see pioneering technologies and smart services: the Dortmund systems supplier will be presenting new developments for all container segments, plus digital solutions and training courses aimed at line optimization.

To the article: Expertise right down the line

CAP INSPECTION TECHNOLOGY

AI sees more

Tethered caps for PET bottles have been mandatory throughout the EU since July 2024, presenting new challenges that call for a clever solution: with the help of AI, the KHS Innocheck TSI checks that the tamper-evident seals on screw closures are intact, correctly seated and not damaged in any way.

To the article: AI sees more

PLASMAX BARRIER TECHNOLOGY

Faster, better, lighter

For many years, tried-and-tested, fully circular Plasmax product protection for PET bottles has proved to be a real success story. And the next chapter is already complete: the KHS technology now scores with higher outputs, lower overall operating costs and even longer shelf lives. To be continued ...

To the article: Faster, better, lighter