Expertise right down the line

Pioneering technologies and smart services: at drinktec, the world’s leading trade show for the beverage industry, KHS will be presenting new developments for all container segments, plus digital solutions and training courses aimed at line optimization.

This year, the Dortmund system supplier’s show booth will center on its holistic line expertise. “KHS stands for progressive technologies and services that can be combined to create smart turnkey systems tailored to our customers’ individual requirements,” states Tobias Wetzel, CSO at KHS. “These generate considerable added value when it comes to line efficiency, resource consumption and the machine footprint.”

As the most important exhibition of the year for KHS, drinktec provides a suitable setting in which to present customers with all new and further developments. “Our employees have achieved really great things in the past few months, demonstrating great passion, heart and expertise,” Wetzel says, praising all those involved in the planning and realization of the booth. The four main topics at the exhibition for KHS will be services, cans, glass and PET.

Focus on services:

completely reliable

KHS’ digital solutions and services are a prime example of the company’s line expertise. The line management section of the booth will be exhibiting both established and further developed software solutions such as Innoline Basic Line Monitoring, Innoline Flex Control and KHS ConnectApp Guide. Under the heading of “line connectivity”, cloud links and secure network architecture for real-time data access and protected OT systems are to be presented. Line coaching is also new this year: it teaches customers practical knowledge that they can use to specifically improve line performance, supported by various digital solutions.

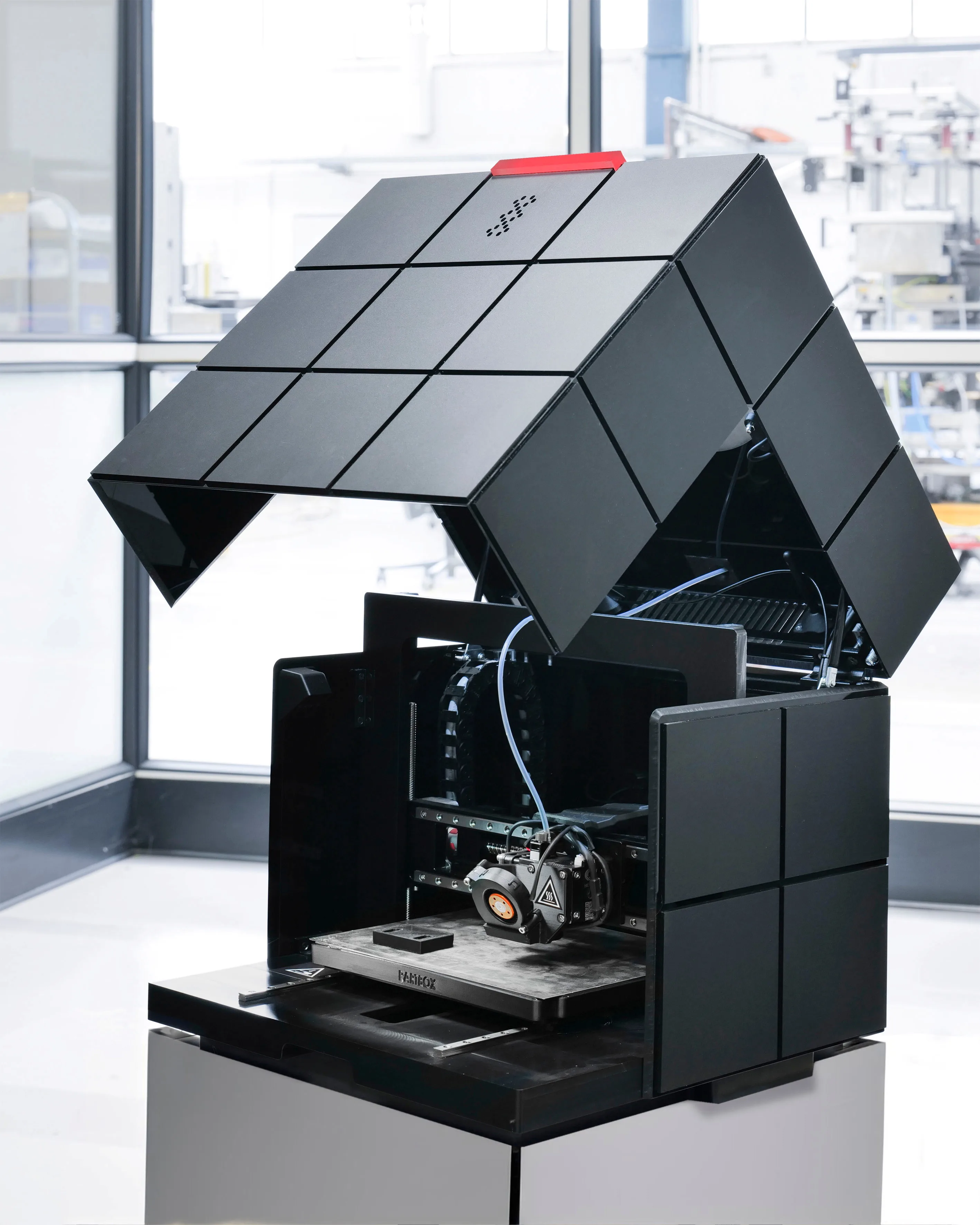

What’s more, the systems manufacturer will also be showcasing its replacement program for cold-glue stations on all standard KHS labelers and a spare parts service featuring products made on a 3D printer.

In the line management section of its show booth, KHS will be exhibiting both established and further developed software solutions such as Innoline Basic Line Monitoring.

At drinktec 2025, KHS will be presenting its spare parts service featuring 3D-printed products, among various other equipment.

Focus on PET:

sustainable and space-saving

The new InnoPET FreshSafe QuadBlock is nothing less than a milestone in the history of the company. For the very first time, it combines four KHS technologies (stretch blow molding, coating, filling and labeling) in a blocked system. This not only simplifies machine operation; it also saves valuable space thanks to its small footprint.

Above and beyond the actual production line, protection of the climate and circularity are key pillars of the company’s strategy. In this context, the new 0.25-liter lightweight PET bottle for still water is a real highlight: weighing just 6.2 grams, it’s one of the lightest containers worldwide. The line-compatible container consists of 100% rPET and is fully recyclable. The bottle is convincing with its high-quality material and design: despite its minimal weight, it meets all functional requirements and is also pleasing in appearance, setting a new benchmark with respect to sustainability, processing and aesthetics.

“Our smart turnkey systems and solutions generate added value when it comes to line efficiency, resource consumption and the machine footprint.”

KHS CSO

Focus on glass:

resource-conserving and hygienic

New to the glass segment is the Innoclean Cascade D that represents the latest generation of double-end bottle washers from KHS. It scores on low energy and media consumption and reduced space requirements. The further development of the established Innopas SX tunnel pasteurizer also centers on resource conservation, hygienic design and – first and foremost – process reliability.

Cooperation with other technology leaders is of prime importance to KHS. One of these is Tyrolon, a specialist for conveying stars and neck clamp systems from Austria. At drinktec, the two companies will be presenting their turnkey machinery for glass and PET lines together for the first time.

The further development of the proven Innopas SX tunnel pasteurizer focuses on saving resources, hygienic design and process reliability.

Focus on cans:

block with lots of new features

Two further strong partners are Ferrum Packaging and H.F. Meyer Maschinenbau. Together with KHS, they’re working to produce compact line systems for the canning segment – with the aim of pooling their strengths as technology pioneers in the best way possible.

One good example of their successful cooperation is the SmartCan Eco by KHS/Ferrum. Thanks to an optimized hygiene concept, the size of the hygiene zone has been reduced by up to 93%. Moreover, with its range of automatic functions and settings, the can filler/seamer block makes product and format changeovers faster. KHS’ developers have also significantly cut the amount of energy and media needed by the machine.