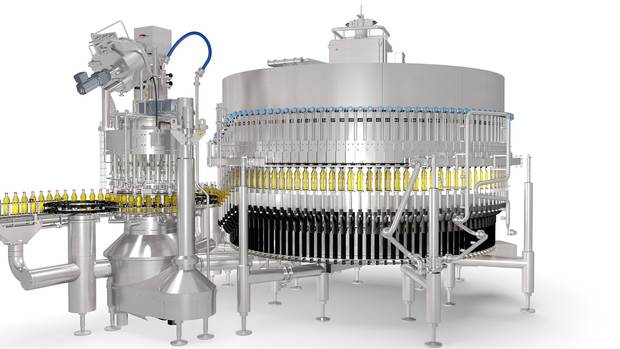

Compact design, high energy efficiency, low investment and logistics costs, simple installation and fast commissioning: these are the convincing arguments that speak for the Innopro BoxFlash flash pasteurizer. KHS first presented this machine, specifically developed to meet the demands of small and medium-sized breweries, four years ago. The technology, proven in practice many times over, is now available for several new areas of application. To date the Innopro BoxFlash was only used in keg filling; as of now it can supply glass, PET and can fillers with the product scheduled for filling.

These supplementary areas of application are reason enough to again take a look at the machine’s main merits. So that the investment can also be easily shouldered by smaller breweries, KHS uses as many identical components as possible in the process engineering.

Minimum installation time

Components taken from other series machines include, for instance, the buffer tank and frame from the Innopro Paramix program, the pioneering three-component blending system from KHS. The buffer tank isn’t installed outside the system as is usual but has instead been placed inside the frame which is dimensioned to fit a standard overseas container. For this purpose, the size of the tank has been reduced by 25% down to a still generous 1,500 liters. The system no longer has to be dismantled for shipping, supplied in parts and repiped and rewired on site, meaning that after acceptance at the production site it can effectively be shipped as a complete unit. This reduces logistics costs by at least two thirds and cuts down installation time on site to the absolute minimum.

Besides attaching the machine feet and mounting the overpressure valve to secure the buffer tank, all that remains to be done on site is to connect up the relevant lines and the Innopro BoxFlash is ready for action. The existing sled systems for product pumps that are also included in the Innopro BoxFlash considerably ease maintenance.

»The space-saving BoxFlash combines precision and efficiency with a very good price/ performance ratio.«

Pasteurization is understood to be the brief heating of beverages to moderate temperatures of up to 75°C to reduce microorganisms and deactivate enzymes. Unlike sterilization, that requires temperatures of at least 100°C, neither taste nor nutritional values are affected by this process.

Optimum pasteurization

The pasteurization temperature can lie between 60°C and 75°C and the heat retention period is 30 seconds. Thanks to optimum regulation there’s no over- or underpasteurization, meaning that the required number of pasteurization units (PU) is always achieved.

As with its big brother, the Innopro KZE C with a capacity of up to 600 hectoliters per hour, the procedure on the Innopro BoxFlash has been perfectly tailored to the requirements of the brewing industry. With a maximum output of 45 hectoliters per hour, the smaller machine is specially designed to cater for small and medium-sized breweries, however. The Innopro BoxFlash can also be equipped with the optional OnBoard CIP module. Two keg parking stations and dosing pumps for the CIP media have been included in the system for this purpose. This allows both the flash pasteurizer and filler to be internally cleaned following production. The system’s overall volume is so small that CIP times can be shortened to a minimum, thus readying the system for production again very quickly.

Finally, the integrated IO-Link communication system improves the monitoring of the extensive sensor setup. It permits constant communication between the sensors and the controller and a permanent feed of diagnostic information right down to sensor/actuator level. This means that the Innopro BoxFlash is prepared for predictive maintenance and – with an eye to Industry 4.0 – all geared up for the future.

Any further questions on the Innopro BoxFlash?

Gerold Tandler

KHS GmbH, Bad Kreuznach, Germany

Phone: +49 671 852 2283

Email: gerold.tandler@khs.com