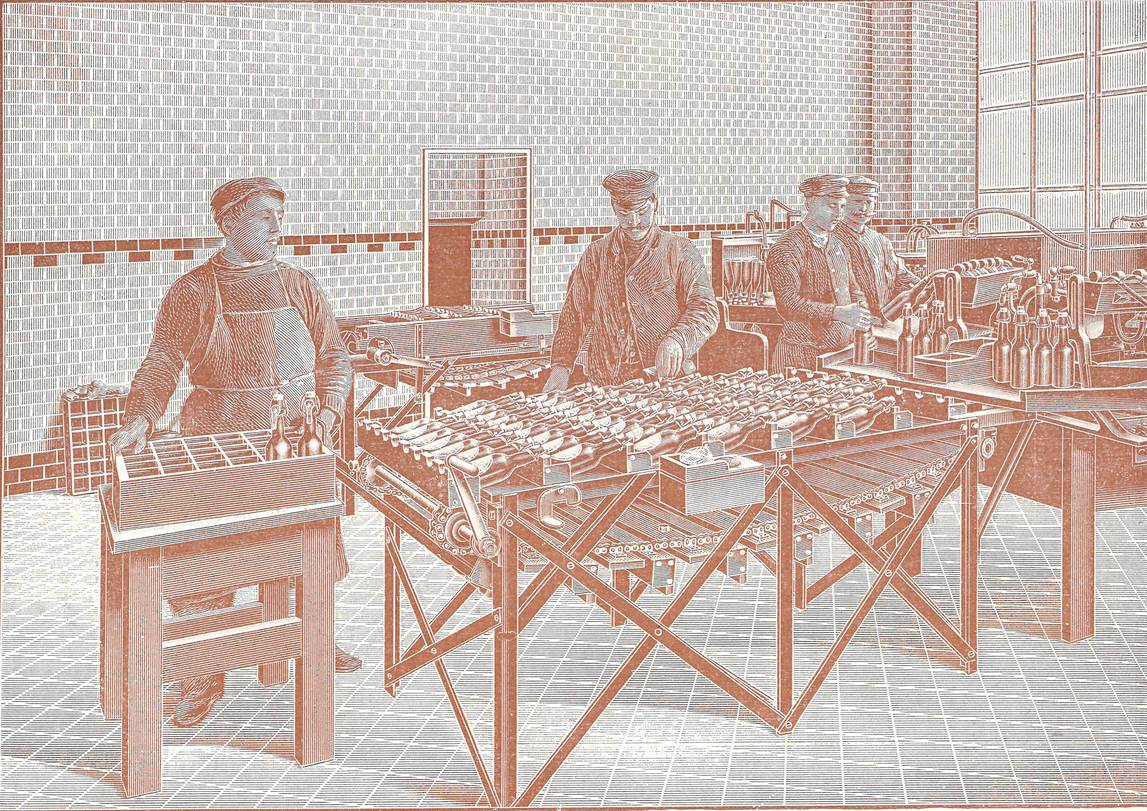

Of excellent worth

Labeling system for manual and power-driven operation

What looks like an artistic copper engraving here is the facsimile of an original illustration from the Holstein & Kappert product catalog from 1906, one year before the former trading company for brewery, malthouse and bottle cellar equipment began manufacturing its own machines. It depicts a patented “bottle labeling apparatus with a conveyor belt” which is claimed to be of excellent worth, avoiding bottle backups and achieving “a very high capacity with the minimum and simplest of operation”.

The device consisted of a bench top, a conveyor, an auxiliary labeling unit attached to one side and space for bottle crates. On the conveyor the bottles could be “completely illuminated in order that the interior of the same can be again inspected by the labeler without loss of work or time”. At the time the price of the large model for a “double column of 20,000 to 26,000 bottles every ten hours and more” was 400 marks.

Down-to-earth high flyer

Native Dortmunder at a traditional Dortmund company

“If anyone took a look at my resume, they’d think I lead a boring life,” smiles Christopher Bentz. “From kindergarten through school and university to my present job at KHS – it looks as though I’ve never left Dortmund.” On the contrary: the 33-year-old loves to try out new things, whether on his travels to exotic countries or remote regions, during the flying lessons he’s taken to experience “physics first hand” or in his job.

For him this also encompasses the change from being a research fellow at the TU Dortmund to working in industry: in 2014 and 2015 he went through an 18-month trainee program at KHS which also took him to the KHS production site in Zinacantepec in Mexico. Originally a specialist in optical measurement technology, the PhD electrical engineer now works in the Line Engineering department as technical project manager for the product configurator. Here, he helps to make processes more efficient and customer friendly, so that KHS is able to not only look back on a long tradition but is also well positioned for the future.

Where love lies

Nest building in Rhine-Hesse

Paul Gustav Schulze was born on August 4, 1870, in Freiberg in Saxony. After training as a molder and caster he and a fellow journeyman ended up in Worms-Pfeddersheim in c. 1890 where both men found work with L.A. Enzinger. While his colleague traveled on to the Saarland as planned, love kept Schulze on the River Rhine. He was soon married to Katharina from Pfeddersheim who bore him four sons and six daughters. Now a master molder and caster, Schulze’s large family lived in two workers’ homes on the Enzinger premises.

Once the first children had flown the nest – all of the boys learned as apprentices with their father – Paul Schulze bought a house on the street which is now Enzingerstrasse and the site of the present KHS factory in Worms. His granddaughter, now 88, still lives here and remembers her grandfather, who died in 1948, as an open-minded, educated man with many interests.