The second fifty years

The economic miracle at Holstein & Kappert,

Seitz and Enzinger

The post-war years were also a time of reconstruction in the mechanical engineering industry: war damage had to be repaired and production restored in order to re-establish the success of the 1930s. This also applied to Holstein & Kappert in Dortmund, Seitz in Bad Kreuznach and Enzinger in Berlin, Mannheim and Worms. Market conditions were favorable: there was a boom in bottled beer and soft drinks which filled the companies’ order books.

After the Second World War had brought international business among Germany’s engineering companies to a grinding halt, the economic miracle and proverbial quality conjured up by the words “Made in Germany” secured Germany a quick comeback on the international stage. At the Seitz-Werke exports rose from 37% in 1950 to over 50% within 20 years – not least thanks to that fact that it operated subsidiaries in France, Italy, Austria, Spain and the United States and a number of general offices all over the world with their own spare parts warehouses. Holstein & Kappert began manufacturing machines at its own plant in São Paulo, Brazil, in 1962, followed in 1971 by a production site in New Berlin, Wisconsin, in the US.

KHS now has facilities in the USA, Mexico, Brazil, India and China and is represented on all the relevant markets worldwide with its own sales and service centers. The name KHS has long been synonymous throughout the globe with high-performance filling and packaging systems for the beverage industry.

The second fifty years

The Novissima bottle washer

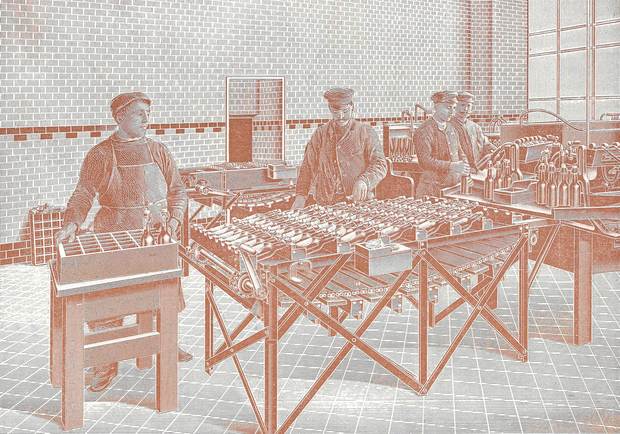

At the beginning of the 1920s Holstein & Kappert developed the Novissima. This bottle washer had three or four drums which not only sprayed out the bottles with cold and hot water but also soaked them in caustic. The prototypes still had a number of teething problems: the clamp closures on mineral water bottles were torn off, for example, prompting competitor Seitz to snidely refer to the machine as a “bottle breaking machine”.

Once the first technical problems were rectified, however, the Novissima principle soon captured the market. Originally sold for 32,000 marks, the machine rapidly became a genuine bestseller which was to be one of the most-frequently sold Holstein & Kappert machines for over 30 years. It was treated as a synonym for the Dortmund machine manufacturer, with letters often arriving from all over the world addressed to the “Novissima Company” on Juchostrasse.

The beverage industry boomed from 1926 to 1930, with manufacturers of equipment for the brewing industry profiting in particular. Holstein & Kappert’s sales increased greatly from year to year, with about 220 Novissimas alone delivered to customers during this period – many of whom were located outside Germany. For many years the Novissima was the declared standard bottle washer, especially for coke beverages which at this time were growing at an exponential rate.

The third fifty years

KHS’ international activities

At the end of the 19th century KHS’ predecessor companies were already looking for sales opportunities well beyond Germany’s borders. Lorenz Adalbert Enzinger, for example, presented his products at the World’s Fair in Chicago as far back as in in 1893, earning much recognition and several awards. In 1912 his company purchased a machine factory in Prague in order to develop the market in what was then Austria-Hungary. At the beginning of the 1930s the first American subsidiary Enzinger Union Corporation was opened in the USA not far from Buffalo, New York.

At all sites it proved especially helpful to focus on qualified training, producing specialized personnel, and on obtaining support from migrant workers from Spain, Italy and other countries in southern Europe.

It was of prime importance to keep up to date with the latest technological developments. At Holstein & Kappert, for example, this meant developing a totally new concept for its bottle washing machines. The Novissima, the drum machine built and sold practically unaltered since the 1920s, was succeeded by the Omega, an innovative chain machine. With its extended range of machinery, which now included bottle washers in the Sterila series and Polyp bottle craters and decraters, Enzinger was once again a company of international standing. Finally, Seitz switched from being a “master machine workshop” to modern large-scale serial production, greatly boosting the company’s sales figures and turnover.

What all companies ultimately had in common was the necessity of also adapting their organizational setup to suit growing demand, whether through the introduction of data processing methods or the establishing of worldwide company sales and service structures.