Not just on paper

Bottles made of paper? Danish startup Paboco believes they’re a climate-friendly alternative to beverage containers manufactured from plastic. We talk to Gittan Schiöld and Tim Silbermann about their challenging journey, their first market-ready product and their future goals.

What qualifies paper – contrary to all expectations – as a material for beverage bottles?

Silbermann: Cellulose, which paper is made from, is a fascinating material. It can give packaging a high degree of stability that beats everything you’d expect from plastic packaging of the same weight. End product paper may not exhibit particularly good flexural properties but Young’s modulus* of its actual fibers almost matches that of steel. To best exploit this, we align the fibers in a conventional production process and subject them to extreme compression while drying. This makes the paper exceptionally robust and gives it a very pleasant surface that enables embossed details to be applied to the outside of the bottle. At the same time, the inside is completely smooth, which is an important prerequisite for the later barrier.

* Young’s modulus = modulus of elasticity; a material property from materials science that describes the mechanical tension.

What makes your paper bottle different from the beverage carton?

Silbermann: Beverage cartons are made of finished, printed and coated cardboard that’s folded and glued immediately before filling. Our containers, however, are made as a single piece. We use primary fibers for this; we don’t glue or weld and don’t use aluminum as barrier protection. You have to imagine the process as a cross between stretch and extrusion blow molding. This opens up a multitude of options when it comes to the bottle design, for unlike cardboard paper can be formed and shaped down to the last detail. This is a great advantage for premium brands especially.

»The packaging industry is currently facing a radical change and needs to act.«

Chief Executive Officer, Paboco

Your vision is that in the near future there’ll be a paper bottle in every hand. How do you aim to achieve this ambitious goal?

Schiöld: We’ve launched our pioneer community to this end. This is a group of partners who include leading world manufacturers such as Coca-Cola, Carlsberg, Absolut, L'Oréal and Procter & Gamble. They share our vision, understand the complexity of innovation and have recognized that we need to create smarter, more sustainable packaging systems. They contribute their respective pioneering expertise to our joint venture: from technology and design to marketing and brand development. We invest together in the form of capital, resources and lots of working hours. We share information on the experiences we gain in the various product categories – throughout the development process and across the entire value chain. This is how we speed up the growth of our project.

What are the benefits of paper as a raw material regarding climate protection? And what are the drawbacks?

Silbermann: Firstly, paper comes from a renewable source that binds CO2. And although trees are harvested to make it, ultimately there’s no net forest loss as long as the raw materials are sourced responsibly. This is crucial for Paboco in launching its system. This is why all of the bottles we currently make are FSC-certified and labeled. We believe in sustainable procurement, transparency and traceability.

One drawback is that paper doesn't have any barrier properties itself, so at the moment we still need a supplementary material to protect the bottled product. This currently consists of a thin 0.1-millimeter lining of recycled PET that’s applied to the inside of the bottle.

The company Paboco

Paboco sees itself as an innovative platform that unites leading international experts for materials, design and technology. Its roots go back to 2010, when Danish engineer Jesper Servé founded the startup EcoXpac. His aim was to develop a paper bottle that replaces plastic and protects the climate. The Carlsberg Group became aware of the company in 2015. With its green fiber bottle the first prototype beer bottle made of recycled fibers was created. BillerudKorsnäs, a leading international paper manufacturer from Sweden which was also experimenting with cellulose-based bottles, then joined the team and at first became a minority shareholder of EcoXpac. As a result, EcoXpac’s expertise in cellulose molding and tool manufacture was supplemented by knowledge of fiber technology, paper manufacture, barrier protection, upscaling and marketing. In 2019 Austrian bottle manufacturer Alpla joined as a shareholder, driven by the desire to promote sustainable packaging innovation. Together, they took over the majority ownership and turned EcoXpac into a joint venture: Paboco or the Paper Bottle Company that today employs about 30 people, assisted by 20 more from the two parent companies.

What do you say to beverage producers and consumers who are disappointed by the fact that the current paper bottle still needs a layer of rPET?

Silbermann: You first have to appreciate that for cosmetics manufacturer L’Oréal, for example, our system uses 70% less plastic than in their former plastic bottle – without the bottle being heavier.

Schiöld: And our current product is of course only the first step on a long journey – but one we’ve consciously gone for: by already launching this MVP** to market, we can develop our bottle more specifically and make adjustments where it needs optimizing. All that we can learn now by introducing paper to existing filling systems, for instance, can be applied to future generations of the container, as the production process of the actual paper bottle won’t change in principle. If we have too many co-dependencies in research and development and want too much at once, we possibly won’t survive as a company because we’ll take too long to launch our product to market.

** MVP = minimum viable product, the first version of a product with just enough features so as to be usable. It aims to help companies quickly learn from customer feedback and avoid erroneous developments that fail to meet user requirements.

Which raw materials do you use for the paper in your bottles and where do these come from?

Silbermann: At the moment we’re using long softwood fibers from Scandinavian pine and spruce – from wood we can source here, if you like. The material is naturally pure and thus inherently food safe. We refine it on site to give the fibers the best possible properties.

Do you also turn other types of wood or recycled paper fibers into bottles?

Silbermann: If we expand to other regions, we’ll of course also be able to use the types of wood common to those regions. We’ve already tested this. We therefore wouldn’t need to ship any Danish raw materials to China but could work locally with Chinese bamboo fibers.

»Considering how successful our first step was, what will be possible in five or ten years from now?«

Project Manager Product Development

Things are a bit different when it comes to recycled paper; technically speaking, we could use it but there are two reasons for not doing so: firstly, it’s not yet been approved for use in packaging as a material that comes into contact with food. Secondly, there’s no certification because reused recycled paper can’t yet be tracked and traced. You therefore can’t be sure whether it’s possibly contaminated or not. The fibers could be laboriously cleaned and bleached, of course, but they would then gradually lose their stabilizing material properties – and this wouldn’t be very sustainable, either.

What have been and still are the biggest challenges for your new development?

Silbermann: Scaling the technology and achieving consistent quality performance are extremely demanding challenges. A lot of this is done by trial and error. At the same time, we’re constructing and operating our first production platform and the paper bottles we make on it are used by our partners for tests, consumer studies and even for product launches. This means that we’re learning simultaneously on several levels as to how we can meet the demands of the industry. This makes our development process very efficient and specific.

What have your greatest accomplishments been thus far?

Schiöld: Our biggest success to date is that we’ve been able to win over fantastic partners who are making the paper bottle a reality together with us.

Silbermann: We’re of course especially proud of the fact that we’ve been able to develop a functional production platform based solely on the experience of our pilot system and get it up and running in just under a year – during the pandemic, at that!

Schiöld: We’ve also made considerable headway with the development of our next bottle generation so that we can already start the transition in the coming year, way ahead of schedule.

And what setbacks have you suffered to date?

Schiöld: I prefer to talk about insights rather than setbacks. The most important one, for example, is “Don’t try to do everything at once”. Other lessons learned are “Keep it simple, repeat and learn” or “Always stay close to the market to stay relevant” and “Things tend to take longer than you think” (laughs).

The 31-year-old from Germany practically grew up with packaging through his father, also employed in this branch of industry. After studying engineering at Munich University, Silbermann worked for Alpla in Austria where he came into contact with Paboco. In January 2020 he then joined the team in Copenhagen as product development project manager.

What’s Paboco’s business model? Do you sell the bottles or the machines?

Schiöld: In principle, it’s Paboco technology. In the short and medium term, we’ll produce and sell the bottles to ensure that we maintain our quality standard. However, when it comes to scalability, this isn’t an option in the long term. But with Alpla, one of our two parent companies, and its around 180 production sites worldwide, there are synergy effects, of course.

What other goals have you set yourselves, such as the next-generation paper bottle and beyond?

Schiöld: The next step is to go from lining the inside of the bottle to coating it and to replace the plastic bottle neck with a paper one. Our ultimate aim is to create a paper container that’s completely biobased and recyclable – and biodegradable should it accidentally end up as waste in the environment. Lots of aspects still need to be further developed here.

Where do you get your optimism from?

Schiöld: The fact that the packaging industry is currently facing a radical change plays right into our hands. It needs to act – and open innovation is the strategic order of the day. Despite these favorable conditions, it wasn’t easy for us to get where we are today. After all, the situation requires that we all work in a completely new way. As a young company we have nothing to lose but can only benefit – even if the circumstances are often extremely challenging.

To date, the 40-year-old Swede has devoted her entire professional career to innovation. After completing her studies in Luleå in the north of Sweden, she worked for Carlsberg for over seven years, in her last post as senior innovation manager. After a brief period as a consultant, she then worked as a venture manager for BillerudKorsnäs Venture. She has held a leading position at Paboco since 2019 and is now its CEO.

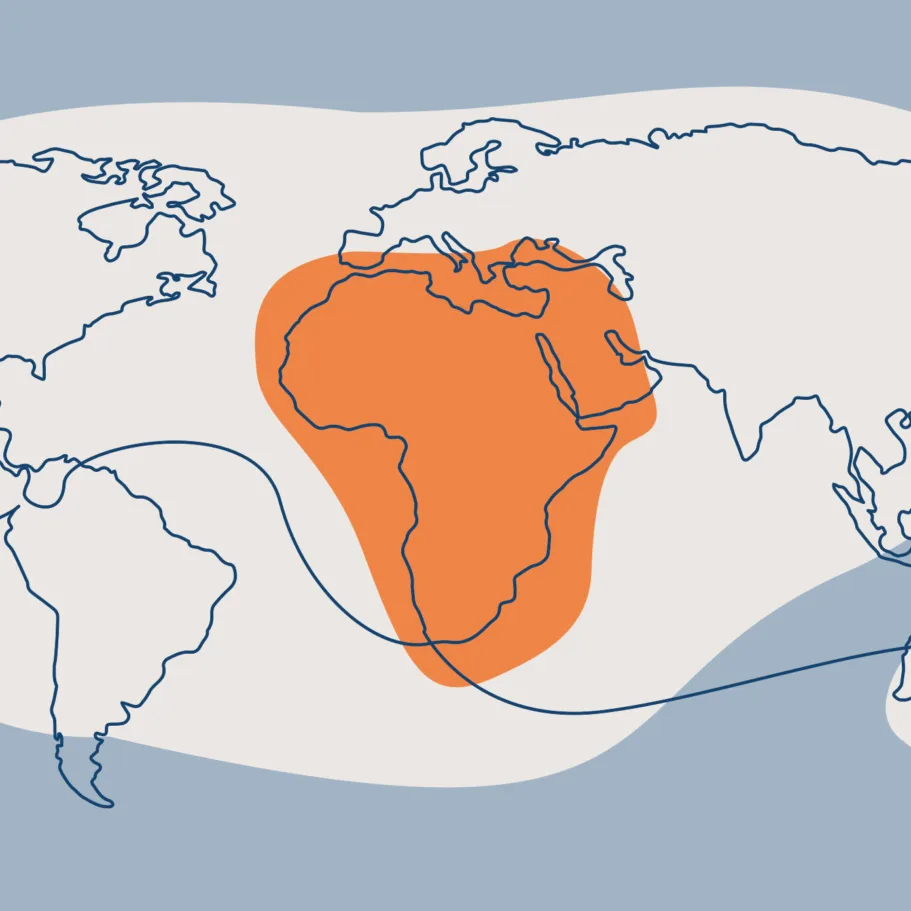

Which markets do you think hold potential for the paper bottle?

Schiöld: As we want to change this industry for good, we need to set ourselves up globally – with huge batches and competitive price levels. We’ll be represented in each market sector and every region where there are now bottles, regardless of whether we replace or supplement glass, plastic or aluminum containers. We’re absolutely convinced that our development is a sustainable alternative to existing packaging systems in lots of different segments.

When will consumers find paper bottles on supermarket shelves?

Schiöld: Very soon. While Carlsberg, Absolut and Coca-Cola aim to launch our product during specific events, Procter & Gamble will launch its version to market later this year.

How will your innovation be received by consumers and which reservations might they have?

Schiöld: The feedback from consumer tests carried out by our partners is extremely positive. The feel of the bottle is very much liked. When the bottle’s chilled, you can feel it – but unlike glass or metal it gives you the impression that the content’s insulated and keeps cool for longer. People can of course question the sustainability of the plastic lining in the bottle but consumers recognize that we’re at the start of our development here and are prepared to go with us on this.

How do you ensure that the paper bottle will be properly recycled?

Silbermann: During development we’re constantly running tests on its recyclability and repulpability***. We’re talking to recyclers to gain feedback on our product and to find out what impact it has on their material flow. One of the main aims of our entire project was always to be recyclable – and we are! Not least because our rPET barrier is not laminated into the bottle, meaning that it can be easily separated from the paper fibers on existing machines.

*** Repulpability = reducing processed paper back down to cellulose pulp.

How do you distinguish yourselves from other visionary bottle or packaging concepts?

Schiöld: We see competition as something positive: it shows us that our industry is ready for change and it keeps us on our toes. The quest for more sustainable options ultimately unites us. We’re thus pleased that more and more paper bottles are being developed and will very soon appear on the market.

Silbermann: At the moment, the focus is on scalability, in which our partners play a major role. From my technological standpoint, considering how successful our first step was, I ask myself what will be possible in five or ten years from now. Here, our imagination knows no bounds!