The small town of Bocholt, with just 13,000 inhabitants, has been home to Brouwerij Martens since 1758. Now in its eighth generation, the family business is run by Jan Martens and his brother Fons. Their offices paneled in wood look as if very little has changed over the course of time. A miniature collection of toy cars lines the shelf, all of them trucks that remind the brothers of when they and their father used to drive their hand-crafted beer to Germany together at the end of the 1960s. Back then they delivered their goods by truck directly to the various branches of up-and-coming discounter ALDI Nord, where they also picked up the empties. At the time no-one could have imagined just how successful both the retailer and the brewery would become. “This is how we turned into an untypical Belgian brewer who didn’t chiefly supply to the hospitality trade but instead became really big as a direct supplier to retail,” explains Jan Martens. His company, for whom the competition is often too conservative, otherwise likes to take an unconventional approach to things.

“We’re very proud to brew Belgian beer whose quality and variety is appreciated the world over,” the 58-year-old states. “We brew from ancient recipes passed down from generation to generation and with the best raw ingredients – but also with a certain desire to experiment. Each winter, for example, our great-grandfather used to brew a top-fermented beer that he hopped every once in a while to make it last longer before selling it in the summer.” What he was actually producing is what we now call a DDH IPA*; in doing so, he was well ahead of his time. You can find out more in the museum at the company headquarters set up in 1979 by the current owners’ father. With an area of 6,000 square meters, it’s one of the largest brewery museums in Europe.

* DDH IPA = double dry-hopped India pale ale.

Tradition and innovation

Don’t be misled by the company’s commitment to its heritage, however; the slogan here is ‘Brewing the beer of the future since 1758’ and Jan Martens tells us what this means. “Our strength lies in the combination of our long tradition and our great passion for technology and innovation.” When it comes to filling and packaging, for decades his company has had a trusted partner at its side in KHS, with whom mutual ideas can be reliably put into practice. The brewery owns a filler from predecessor company Holstein & Kappert from the 1960s, for instance, that is still in operation.

“Martens has long been an important strategic partner for us,” smiles Herman Miseur, head of Sales for KHS Benelux. “The company is strongly geared towards high-tech. There are applications here that we can test many of our new developments on before we finally roll them out to market.” Jan Martens adds, “Compared to many breweries that are too small and those that are far too big and rather inflexible, we’re more open to new ideas. We’re interested in the trends on the market and exploit all ways of becoming even more efficient and saving even more resources in production. This puts us on the same wavelength as KHS. And unlike concerns with relatively lengthy approval processes, we’re quick to reach a decision.”

»We see what the trends are and exploit all ways of saving even more resources in production.«

Pioneering achievement: beer in PET bottles

Martens’ partnership with the Dortmund engineering company saw one of its many highlights in 2003 when the one-way deposit system was introduced in Germany. In the November of the previous year ALDI had asked the brewery to start thinking about filling beer into PET bottles. Martens and KHS quickly came up with a suggestion that had the discounter convinced. While another beer producer latched on to the idea with a multilayer bottle, the brewers in Bocholt specifically opted for a PET bottle with a KHS-patented Plasmax barrier coating. In this process a wafer-thin layer of glass is applied to the inside of the bottle to prevent carbon dioxide from escaping and oxygen from penetrating the wall of the PET container that is permeable to gas. This means that the quality of the beer doesn't suffer and the beverage stays fresh for longer. The glass layer can simply be washed off during the recycling process.

“Even back then I thought a multilayer solution unsatisfactory from an ecological point of view,” Martens remembers. “The bottles can’t be recycled as the various materials can no longer be separated from one another. With the coated system only the pure PET remains that can then be collected by type and recycled.” He also liked the idea that the added value from coating was generated within the brewery and not for the supplier of the preforms, as with the multilayer bottle.

In August 2003 trucks carrying the first plastic bottles of beer trundled over the border. This was big business for Martens, for 500,000 hectoliters were sold in one fell swoop, then amounting to about a third of its total output.

The Belgians now produce around four million hectoliters of beer per annum and are thus one of the 50 largest brewers in the world – a ranking that incidentally isn’t important to them. Like its customers Martens prefers to fly under the radar rather than tout its wares with pithy statements. Since 2006 beer has been produced not just at its headquarters in Bocholt but also in a state-of-the-art facility in Kaulille, just eight kilometers down the road. Here, for example, two KHS canning lines with a capacity of up to 60,000 and 90,000 cans per hour are in operation. What’s more, up to 40,000 bottles per hour are filled on each of two separate PET lines. Both are equipped with InnoPET Plasmax® coating machines.

Film-free multipacks

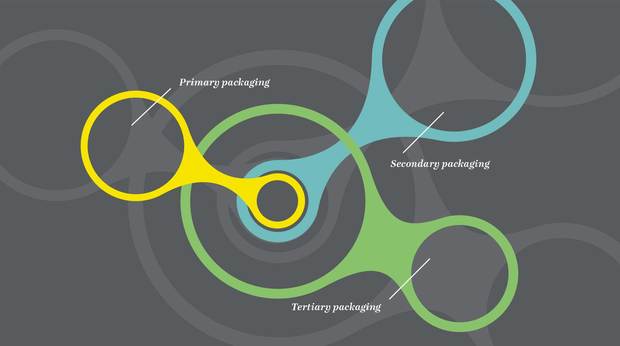

Last year Martens itself approached its retail customers with a further technological coup: Nature MultiPack™ developed by KHS joins beverage bottles together not with shrink film but with dots of adhesive to form a stable yet easy-to-separate pack (also see the article ‘Full speed ahead!’ from page 18 onwards). Herman Miseur explains what Martens and its customers find convincing here. “As opposed to classic film packs, here we reduce the carbon footprint by up to 70% – from manufacture of the packaging to its disposal. Nature MultiPack™ saves up to 90% in packaging materials on a pack of six PET bottles, for instance. And finally, the system not only cuts down on the amount of film used but also on the heating energy otherwise needed to shrink the film in the shrink tunnel, using up to 67% less.”

The retail companies, themselves under increasing pressure regarding the packaging of their products both from consumers and various legal provisions, were convinced by Martens’ proposition. It helped that Martens isn’t just setting standards with innovative secondary packaging from KHS but also with the primary packaging; the brewery is one of the first to manufacture its bottles entirely out of recycled PET (rPET). They’ve also reduced the weight of the 0.5-liter bottle to under 20 grams, thus disproving the general theory that a container made of 100% rPET must be heavier than one made of virgin material. Following successful tests, the Nature MultiPack™ consisting of recycled bottles is to be rolled out across Germany and Spain. In the meantime, investigations are underway to see if the packaging system can also be introduced for cans.

Cost of course plays a major role in innovations such as these – with the Bocholt brewery no exception here. However, Jan Martens knows that new technologies are at first more expensive than their established alternatives. He also emphasizes that the prime concern for him is the TCO or total cost of ownership that covers all operating costs from the use of materials through energy consumption to maintenance. For the record, he doesn’t see himself as a low-cost supplier who can only do business by keeping prices to a minimum. “We’re an indispensable partner to our customers in the private label sector because we’ve been in the business for so long and understand both retailers and consumers and their specific requirements,” he stresses. “We see ourselves as a systems provider who gives its partners the right answers to their questions.”

Jan Martens is convinced that sustainability will continue to grow in importance for his branch of industry. He believes his company is well equipped to tackle issues such as the carbon footprint, use of materials or energy and water consumption. At the moment he’s experimenting with the recovery and reuse of water in order to reduce consumption levels that are already very low. The brewery now only needs 1.8 liters of water for one liter of beer; the worldwide average is about five liters. “As a producer of FMCGs** who shifts huge volumes, we want to be in a position to tell our customers what’s economically sound, where we’re heading and what we can do,” states Martens. “Like when buying a car, where carbon emissions have long been a major factor, or a washing machine, where you scrutinize the water consumption and energy efficiency class, consumers will also judge our sector with an increasingly critical eye – not just as regards the packaging but also the product itself. It’s time for us to take on this responsibility.”

** FMCG = fast-moving consumer goods.

Any further questions?

Herman Miseur

KHS Benelux B. V., Breda, the Netherlands

Phone: +31 76 5723 234

Email: herman.miseur@khs.com