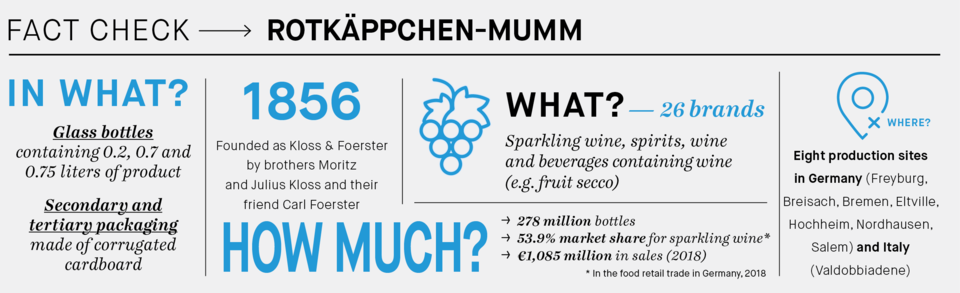

Rotkäppchen and Mumm are two brands that all Germans are familiar with. Rotkäppchen, established in 1894, is a sparkling wine from Freyburg in the Salle-Unstrut wine-growing region. In 1988 VEB Rotkäppchen in the former German Democratic Republic sold 15.5 million bottles of sparkling wine topped with the red cap that lends it its name before being taken over by a trust company one year after the fall of the Berlin Wall and sold in a management buy-out three years later. In 2002 Rotkäppchen, by then a national market leader, took over brands Mumm and MM, with the sparkling wine for these made by Matheus Müller in Eltville in Germany’s Rheingau.

However, it’s a little-known fact that behind these two traditional names lies a whole host of other brands and products added to the diverse portfolio through numerous acquisitions. These now include various other sparkling wines such as Jules Mumm and Geldermann, brand spirits Chantré, Nordhäuser and Eckes Edelkirsch and wines like Blanchet – products which are produced, filled and packaged in countless variations at seven facilities in Germany and one in Italy.

Big variety in a small space

Accordingly, the range of packaging is extremely diverse in which the bottles are distributed to stores, where they attract attention on the shelves, or are wrapped as gifts, making production something of a challenge. “Up until now we needed a separate packaging machine for each format,” explains Lars Grebe, head of Sparkling Wine at the Rotkäppchen-Mumm Enology Competence Center in Eltville. This is where Mumm, MM Extra and Rotkäppchen fruit secco are filled into 0.75-liter bottles and piccolo containers (known as ‘little MMs’) holding 200 milliliters. “Our production site is in the middle of a residential area bordered on one side by the River Rhine. There’s therefore no room to expand,” states Grebe. “As we only have a very limited space at our disposal, it’s imperative that we make efficient use of it.” Rotkäppchen-Mumm was also guided by this principle when it began thinking about how it could make its packaging area more powerful and flexible in order to satisfy growing market and marketing requirements.

One for all

Following a long phase of orientation and planning at Rotkäppchen-Mumm the contract was awarded to KHS. Thanks to KHS’ cooperation with Schubert, the specialist for carton packaging from Crailsheim, Germany, as the sole bidder the Dortmund systems supplier was able to master this mammoth task using just one machine. And what a machine it is! The plant engineering installed in September 2018 includes 13 sub-machines and is an impressive 33 meters long. This is anything but small, yet the combined Innopack TLM packaging system scores on performance, quality and adaptability on several counts, making any additional machinery totally superfluous. “Compared to our previous standard we’ve doubled the line capacity for our gift packs of one and two bottles and can now package up to 33,000 bottles an hour,” smiles Grebe, who thus far has run the machine in two-shift operation.

However, speed isn’t everything, as he is keen to emphasize. “While a shipping carton of 24 can get away with minor flaws, we want 100% quality for our gift packs, so there’s practically no leeway here.” After all, the person receiving the gift should have fun unpacking it, for we all know that beautiful wrapping makes a gift all the more enjoyable.

»Compared to our previous standard we’ve doubled the line capacity for our gift packs of one and two bottles.«

Prepared for the future

The most important criterion for Grebe and his colleagues, however, was flexibility. Whereas on placement of the order there were nine packaging formats listed in the requirement specifications, during commissioning a few more were added, with the machine now processing eleven different types of cardboard packaging. This is by no means the end of the story, however. “I’m convinced that we’re also well able to meet future demands from the retail trade with our new technology,” Grebe says. “One prospective option could be the packaging of 0.75-liter wine bottles, for instance, and also new format sizes, such as packs of three or five.” Another aspect of the machine’s flexibility is that it has been designed so that only a few format changeovers are necessary and the tools can be switched over relatively quickly. “We convert the machinery a maximum of four times a week. Depending on whether we’re making a hard change from fruit secco to sparkling wine, where we have to change over several transmodule plates, or just switching the heads on the KHS pick-and-place packer, this only takes 30 to 90 minutes,” Grebe happily remarks.

In order to understand how complex the packaging tasks are at Rotkäppchen-Mumm, let’s take a look at the individual steps involved when the machine packs individual bottles into gift packs and then shipping cartons, for example. Here, no fewer than ten of the 13 sub-machines are used. On the first two up to 550 cardboard blanks per minute are extracted from the magazines. Robots grip the individual packs that are arranged in a row, erect them and place them on a transmodule which travels through the machine to the next steps in the process. The flaps are glued before in the next sub-machine the underside is sealed and the gift pack is turned upright and placed on a second transmodule segment in rows of two. At the next station the bottles are picked up by the KHS Innopack PPZ pick-and-place packer and carefully placed in the gift packs which are open at the top. The top side of the cartons is then also sealed; next, these are pre-grouped on one of two further transmodules so that they can be packaged for shipping.

Patented transmodules

The last part of the packaging process prepares the goods for shipping. As with the individual packs blanks are destacked from the magazines for the secondary packaging, erected, glued and placed on their own transmodule segment. In the penultimate sub-machine the sealed gift packs are lifted into the secondary packaging in groups of four by six products at a rate of up to 23 times a minute. In the final station the top of the shipping carton is also sealed.

The various sub-machines are linked by Schubert’s patented transmodules. Thanks to their inductive energy supply and wireless transfer of data and signals they glide back and forth on their rails along the entire line without interfaces. Maximum availability and the best possible efficiency are ensured by a considerable reduction in the number of mechanical parts.

One can imagine that the planning, installation and commissioning of such a complex machine was a huge challenge for all involved. “The time slot for installation was extremely ambitious,” remembers Max Schwaiger, the man responsible for Packaging Product Support at KHS. “Thanks to our good project management we were able to keep to the deadlines. This wasn’t a matter of course as the growth in the number of formats during the process resulted in a certain level of complexity. We’re used to coordinating the various plants from our work in line production, however – and our colleagues at KHS and Schubert are an experienced team.” One example of the project’s complexity was that the KHS pick-and-place packer had to be transported from KHS in Worms to Schubert in Crailsheim for the factory acceptance test and integrated into the system there.

Owing to the limited space at the final place of installation in Eltville the system not only had to be completely dismantled and brought into the building horizontally. With the help of 3D simulation calculations were also made with millimeter accuracy as to how much space the machine column on the pick-and-place packer would need during erection of the machinery. In the end the ceiling grid only had to be dismantled and cut out at this point – a work of absolute precision.

Total enthusiasm

Lars Grebe is delighted with the cooperation between KHS and Schubert. “They make a really strong team. We’d never have come up with the idea of Schubert and its transmodules on our own as we associate these with totally different branches of industry – from pharmaceuticals to candies. Only in conjunction with KHS’ expertise in the beverage sector and particularly in the handling of bottles, which for us is a vital asset, have we found the perfect solution.” For Rotkäppchen-Mumm one big success factor was also that there was only one point of contact in KHS’ system of project management instead of several different entities which would have had to have been coordinated by Eltville.

In the meantime the new technology also has the system operators convinced. “Over the years our colleagues of course build up a kind of emotional bond with their old machines which can be ‘knocked back into shape’ with a hammer if need be. The overall function and look of the new machine are so fascinating and convincing, however, that initial skepticism has long given way to total enthusiasm,” Grebe grins. He also has a glint in his eye when he waxes lyrical about the system’s design where attention has been paid to every last detail – right down to the lighting. “It’s a bit like a really good model railway – just much, much bigger.”

Any further questions?

Wolfgang Augel

KHS GmbH, Dortmund, Germany

Phone: +49 231 569 1635

Email: wolfgang.augel@khs.com