When one of the largest chocolate manufacturers in the world is on the lookout for a real packaging innovation, KHS doesn’t beat around the bush. As soon as traditional American company Hershey’s inquired about a cube package in 2015, the Dortmund systems supplier entered the ring and submitted an offer. The rest is history: since the middle of 2017 the first two KHS machines have been up and running in Hershey, the quarter named after the company founder which Hershey had built in Derry, Pennsylvania, for his employees and which is affectionately known as ‘Chocolate Town, USA’.

Scott Fedor, as director of Global Replatforming and New Technology Engineering the man responsible for new packaging at Hershey’s, is more than pleased with what has been achieved. In the past, with the margins of its products clearly in mind, the company chiefly opted for a pouch solution for its primary packaging, devoting more of its energies to the secondary packaging. Fedor explains why Hershey’s ultimately began to consider introducing a new form of packaging. “Many consumers and retailers often lamented that it isn’t easy to distinguish which of our candy bags you’re picking out of the box. We therefore began thinking about how we could optimize our brand image at the point of sale and make our brand more eye-catching.” It was soon clear that this process would take longer than just a few weeks. Fedor has a quick answer to the question of how many ideas were evaluated and then abandoned during the course of the project. “We named our designs after the letters of the alphabet, numbering each letter version. The variant with the working title of J8 proved to be the ultimate success; this gives you an impression of just how many alternatives we devised, tested and subsequently discarded.” The result is a stackable, resealable cube which looks good from all four sides on the shelf and which presents Hershey’s products (which are otherwise fairly similar in appearance) effectively and distinctively.

The precautions taken also included converting a former warehouse and equipping it with air conditioning especially for the new machine and only giving the core team access.

Strictly confidential

The cryptic working title of J8 points to an important detail in the cooperation between Hershey’s and KHS: confidentiality. The aim here was to completely prevent any of the other companies involved in the project from implementing the joint idea on its own initiative. John Turner, chief operations officer at KHS USA, describes how carefully the two partners proceeded. “Certain aspects of the new machine couldn’t be advertised as we otherwise would’ve divulged too many details. Even our research into subcontractors, such as film or thermoforming machine manufacturers, usually took place without their knowing.” Scott Fedor sums up. “It was a huge challenge to develop something completely new without being able to talk about it. This was also why we opted for KHS: we could trust that our information was in good hands.”

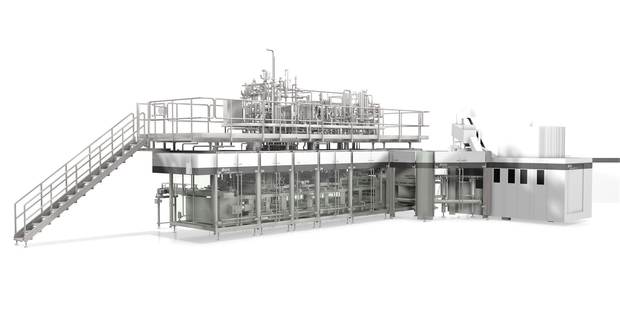

More line than machine

Innopouch Cube

With a total of seven stations the Innopouch Cube is more of a line than a single machine. Among other features it has two machines which form the cube walls, a filler and two sealing robots. The cubes are conveyed by an iTrack system.

The basic area of the cube is 103.5 x 103.5 millimeters, with the height varying according to the format; the classic variant, for instance, is 78.8 millimeters high and designed to hold between 250 and 340 grams, depending on the product. At 65 millimeters in height the slightly smaller gift package can contain 200 to 250 grams of candy. The film used has a thickness of 0.08 millimeters.

The Innopouch Cube has a capacity of up to 100 cycles a minute.

From scratch

For Roger Calabrese, head of Research and Development at the KHS production plant in Sarasota, Florida, J8 is also something very special. “In all the 32 years I’ve been working I’ve never seen a project quite like this,” he emphasizes. “Usually when we build a new machine we can fall back on existing technology and develop this further. Here, we really did start from scratch.” During the process the packaging design was adapted several times with the aim of optimizing the base and lid of the cube, improving wall forming and modifying the insertion of the base and lid, for example. Calabrese also finds the chocolate manufacturer’s courage unusual; the customer was so convinced by the success of the joint mission that it ordered a second machine before the first one had been delivered.

‘Hershey cubed’, as the packaging innovation is now officially called, was initially only produced on the two prototypes for Chocolate World – Hershey’s own factory showroom and sales area. “This project presented us all with huge challenges under enormous time pressure,” states Dr. Mohamed Astitouh, head of Project Management for KHS USA, Inc. in Sarasota. “Following the first product test two machines then had to be readied for the production of several million cubes for the nationwide market launch in a very short time indeed.”

In time for the Christmas holiday season the first products were supplied to various supermarkets where they were sold off the shelf and in secondary placement and enthusiastically received by consumers. The next cubes were quick in coming and sold in supermarkets nationwide for Valentine’s Day. The new cube offers a number of distinct advantages. “Consumers spend exactly 30 seconds in the supermarket candy aisle – if they can’t find what they’re looking for in this short space of time they move on and continue shopping in the other product categories,” says Scott Fedor in his description of consumer habits. “A better brand impact is therefore naturally essential for us. The problem of the contents of an open bag being scattered throughout the entire pantry is also solved by a pack which can be stacked and resealed. Hershey cubed also looks so nice on the kitchen counter that you can simply leave it there so that the entire family can help themselves whenever they feel like it,” smiles Fedor.

Your contact on this topic

Dr. Mohamed Astitouh

Head of Project Management

KHS USA Inc., Sarasota, USA

Phone: +1 941 448 0441

Email: mohamed.astitouh@khs.com