You can see just how productive the KHS packaging specialists in Kleve are merely by looking at their output; A total of 145 machines per year leave the production shops on the Lower Rhine – and the trend is for more. At peak times one machine a day is sometimes loaded onto trucks. If you think this sounds like seasonal business, you’re not far wrong; as a rule, beverage producers tend to upgrade their technology prior to the busy summer months before then concentrating exclusively on bottling and distributing their products once the season is underway. “These peaks, which we experience from November to April as a result of the above, are becoming more and more extreme,” says Karl-Heinz Klumpe, packaging product manager for KHS in Kleve, whose sales colleagues have their hands full preparing offers right up to the end of each year. “Although we already supply to a number of customers who produce south of the Equator, these seasonal fluctuations persist.”

“Even in the 1960s Kisters had a unique position in Europe.”

Kisters pioneer

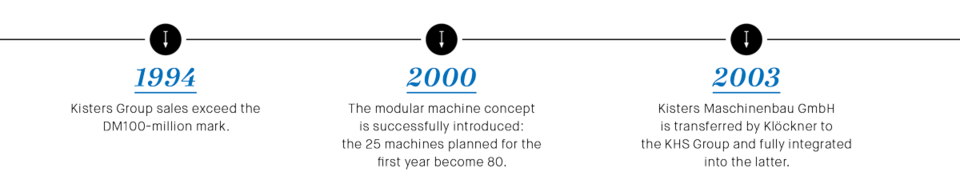

As performance is not measured in capacity alone, it’s worth taking a look at the company’s technological powers of innovation. This is best done together with Werner Oster, head of Project Processing, who will soon be leaving the factory in Kleve to start his well-earned retirement after 46 years of working for the company. In 1970 he began training as the first apprentice electrician in a company whose name was already a worldwide synonym for advanced packaging technology. “In the 1960s Kisters was the first manufacturer of packaging machines in Germany which could run a number of different applications. Thanks to their interchangeable format sets, which could be switched over in just ten minutes, operators didn’t need to procure a second machine. This gave Kisters a unique position on the European market at that time.” In the 1970s Kisters developed the first own company programmable logic controller (PLC) for a packaging machine in the world, with which processes, the machine status and fault messages could be displayed visually for the first time. Oster continues, “At the end of the 1980s we were then the first in packaging to use several local servodrives on one machine instead of the then standard central drive through a main shaft, for example. This was only possible as we had our own PLC. Even back then this was designed in such a way that logical parameters, such as millimeters, seconds and angular dimensions, could be entered in place of the otherwise usual hexadecimal input,” he remembers. “We also always made sure that even the finest electronics could be controlled by operators wearing the thickest gloves.” In order to ensure the continuation of the company beyond their own working lives, in 1987 the company founders first sold half and then the majority of their shares to Klöckner Mercator Maschinenbau in Duisburg. In 2003 the Klöckner shares were transferred to KHS and Kisters Maschinenbau GmbH was fully integrated into the KHS Group.

Modular machine program

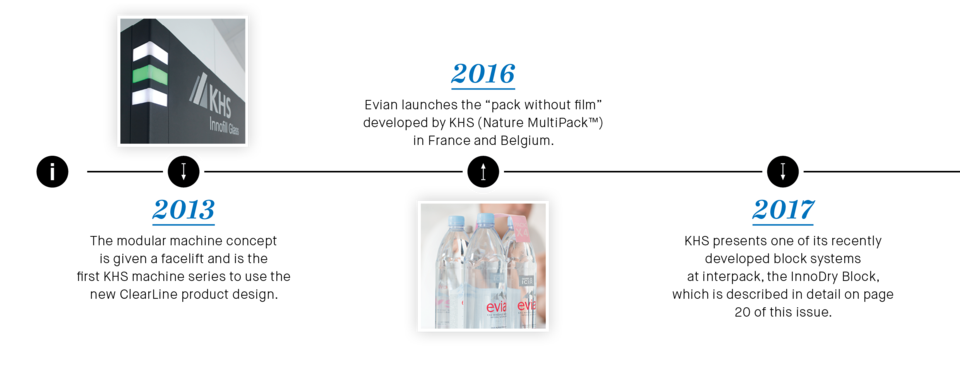

In the year 2000 the launch of a modular machine concept still in use today – now in a further developed form and since 2013 also in the KHS ClearLine design – was a veritable quantum leap. Klumpe was a witness to this. “For the machines sold to date the demand for conversions including spare parts management was becoming ever more urgent.” The development of a modular program was the logical consequence of this, yet this proved a demanding undertaking. Klumpe tells us why. “Reorganizing the program called for an extra 60,000 hours of design engineering – in addition to our ongoing operations. Our order books were full. This meant that in part our design engineering departments really were working day and night, seven days a week.” The result was a structure within which the various process modules could be highly flexibly combined with other optional modules. The newly developed series proved such a hit on the market that the expected number of orders was vastly exceeded during the first year alone. The company was so influential within its sector that the name “Kisters” had long become a byword for tray packers.

The most recent exemplary product borne of the KHS packaging experts’ wealth of ideas is the Nature MultiPack™. Here, PET bottles are joined together using a specially developed adhesive instead of being packed in shrink film, plastic rings or cardboard. This new packaging variant has been designed to withstand shipping and marketing logistics while allowing the consumer to easily remove the individual bottles from the multipack. Nature MultiPack™ is just one of the many patent-protected innovations – 427 in all – the inventors at Packaging Technology in Kleve have come up with. “At our production plant we look back with pride on a long tradition as drivers of innovation,” ascertains Christopher Stuhlmann, head of the Packaging Technology Product Center. “Thanks to the consistent new and further development of customer- and consumer-oriented packaging solutions and machines we make sure that we keep our excellent reputation and that we can convince our customers with our disruptive innovations time and again.”

The development of the market suggests that this is a good idea. Karl-Heinz Klumpe sums it up as follows: “Even if KHS in Kleve is still heralded as a pioneer in the packaging industry, the competition has caught up. We will therefore defend and even increase our competitive edge with pioneering innovations.” Few systems manufacturers have such a strong international base as the Dortmund systems supplier, however – especially when it comes to service, which KHS is progressively localizing by installing a growing number of highly qualified specialist personnel at regional locations worldwide.

“We take the challenges of the market seriously.”

Effective instrument

Another form of market persistence is to work closely together with clients on the use of their machines. Constantin Siemons, Project Processing for Africa/Middle East, lists which concrete services customers can expect. “We want to continue to stage individual customer events and five years ago reactivated a very effective instrument in this regard: the customer workshop, where our customers, their material suppliers and we as the machine manufacturer can discuss requirements and share experiences. Here, we focus on the quality, storage and handling of packaging materials. Regarding development, in the future we will install a complete machine at our Technical Center, on which customers can test various shrink films together with us, for example. Participants in the workshop also gain an insight into future planned developments and we can use this opportunity to compare customer requirements with future technical systems.”

Trust is vital

His colleague Klumpe confirms how important this topic is in particular. “A trusting relationship and addressing individual concerns are vital when providing customers with technical advice. We take the challenges of the market seriously and concentrate on these intensively,” he observes. “We must invite as many customers as possible to Kleve in order to make the contact between them and our factory as intensive as possible. It’s a bit like at home; if you never have guests, you’ll never be a good host. And the benefits are obvious: direct information from the market is always the best information.” Klumpe is convinced that with this approach KHS will secure itself an advantage on the market in the future, too. “Unlike the competition we cater for customer requirements according to the customizable machine formula by supplying special systems. This is rewarded and our customers respond positively, telling us that they can feel how strongly the team in Kleve fully identifies with KHS products.”

Flexibility is a central theme for customers. This is why the people in Kleve are pleased that packs such as baskets and clusters are now also possible through KHS’ cooperation with packaging machine manufacturer Gerhard Schubert from Crailsheim. This supplements KHS’ own product portfolio and generates greater flexibility. This partnership has another good side effect when we look at the various networking aspects; Schubert has lots of contacts in the food industry which KHS can also profit from.

When asked what the future will bring the packaging industry, everyone is in agreement. “Smart machines are a major issue,” states Klumpe. “These are machines which test the packaging material themselves, for instance: in other words, they assess whether the cartons or cans are in order or not and which ones have to be rejected.” Oster adds, “We already have carton machines which supply themselves with packaging material, some with the help of robots. One spontaneous example is that of a Finnish customer who told us that he didn’t want to have to refill any cartons during an eight-hour shift. This will be the same for film.” Siemons adds, “Customers are frequently asking for machines which can make format adjustments fully automatically – without the need for any format parts whatsoever. However this is achieved, future machines will be able to adapt to an ever greater variety of formats faster and more reliably. This is the key brain teaser for all of us in this sector.”

At the end of the interview we want to know how many packaging machines from Kleve are now up and running throughout the world. The answer is over 3,700, with the oldest from the 1980s, as Werner Oster concludes. Many of these will still be hard at work when he has long retired.

Pioneers from the Lower Rhine

Maria and Karl Kisters

The name Kisters is inextricably linked to the KHS production site in Kleve. The perfect complement – Maria a businesswoman with a good grasp of technology, Karl a master mechanic with a wealth of ideas – the couple founded Kisters Maschinen- und Apparatebau GmbH in 1957. Their company initially made machines for the shoe industry. The Kisters quickly turned to other regional products and within a few years gingerbread cutting machines, film-wrapping and gluing units for chocolate candy boxes, waffle folding machines and a machine for peanut-flavored chips were also included in the portfolio. At the end of the 1960s the company was renamed Karl Kisters Maschinenbau GmbH and from then on concentrated solely on building packaging machines for the food and beverage industries.

By the mid-1970s Kisters machines were being sold all over the world. At this time Karl Kisters outlined the mission of his prospering company: “What we make must last forever.” This not only expressed Kisters’ high demand for quality but also the fact that Kleve would rather not hear anything more about a machine in its next 20 years of continuous production once it had left the factory due to the lack of an extensive service network at that time.

During his travels Karl Kisters acquired orders which often presented his engineers with quite a challenge – not least because the smoker usually sketched the machine layout on the inner wrapper of his pack of Finas cigarettes. Should his engineers on occasion not have come up with a way of realizing his ideas, on Monday Kisters would turn up at the factory with a solution he had developed in his garage at home over the weekend. Maria Kisters, responsible for the company’s commercial welfare, never came to the office without her dog – and if the boxer didn’t like someone, it was difficult for this person to convince the couple otherwise in a job interview.

People in Kleve still fondly remember Maria and Karl Kisters who sponsored and enriched life in the city in many generous ways. So that this is also the case in the future, the Kisters Foundation financed by the company’s sales profits is used to promote the training and education of young people.