Some things take time to develop in Georgia. One of these is the consumption of beer in a country with around 4.5 million inhabitants. Before the demise of the Soviet Union about 60 liters of beer were bought per person and year, with this figure falling to 10 liters per capita at the end of the 1990s and now up again at 25 liters. For Tsezar Chocheli, owner of the Georgian Beer Company, the average low income is the main reason for the very slow increase in the country’s consumption of beer. Yet Chocheli has a sense of perspective. “In the medium to long term I’m reckoning on us again achieving a per capita consumption of over 60 liters of beer per annum.” And of course he wants his brewery to be in on the act.

This is typical of a man who sets a pace rarely seen in this country. Within a few years he founded two breweries and sold many hundred thousand hectoliters of beer. He subsequently had to give up his companies – and a little later started a new brewery which after just under two years is up at the top of the industry (see ’Entrepreneur profile’).

König Pilsener under license

A major factor in the success story of this rising star is that Chocheli is uncompromising in his commitment to quality. With the exception of Georgia’s excellent water, his Georgian Beer Company only processes ingredients sourced in Germany. The company was also the first brewery in the world to be given permission to brew König Pilsener under license. The boss has great aspirations. “We didn’t want to brew any old German beer under license; we wanted to brew the ’King among beers’ [the brand’s slogan].” His success on the market has proved him right.

Chocheli’s general director, Vasili Sulkhhanishvili, tells us how it all came about. “At the König Pilsener site in Duisburg in Germany we organized a blind tasting session, where professional beer tasters were challenged to find out whether the König Pilsener in their glasses was made in Germany or Georgia. Nobody could find even the tiniest difference. This finally convinced our German partners that they’d made the right decision in granting our brewery the license.” The brewery now realizes up 25% of its beer sales with the German premium brand with local beers Zedazeni and Khevsuruli notching up 50% and 25%.

Tsezar Chocheli explains. “Our beers cost more than those of our competitors yet they’re still growing faster. Georgians pay very special attention to quality when they treat themselves to a beer.” Accordingly, the Georgian Beer Company has been presented with many awards in international competitions. In the year 2013 alone it won a total of six gold and three silver medals for its specialty beers.

The company’s uncompromising strategy of quality and high pricing also applies to its non-alcoholic beverages. There are currently five soda pops (all with natural flavorings) under the Zedazeni label on the market in the flavors pear, lemon, grape, tarragon, and cream soda. With these the company holds a 25% share of the bottled soft drinks market in Georgia. The range was also recently extended to include the country’s first energy drink; shortly after being launched to market Chocheli was selling 100,000 cans of it per month.

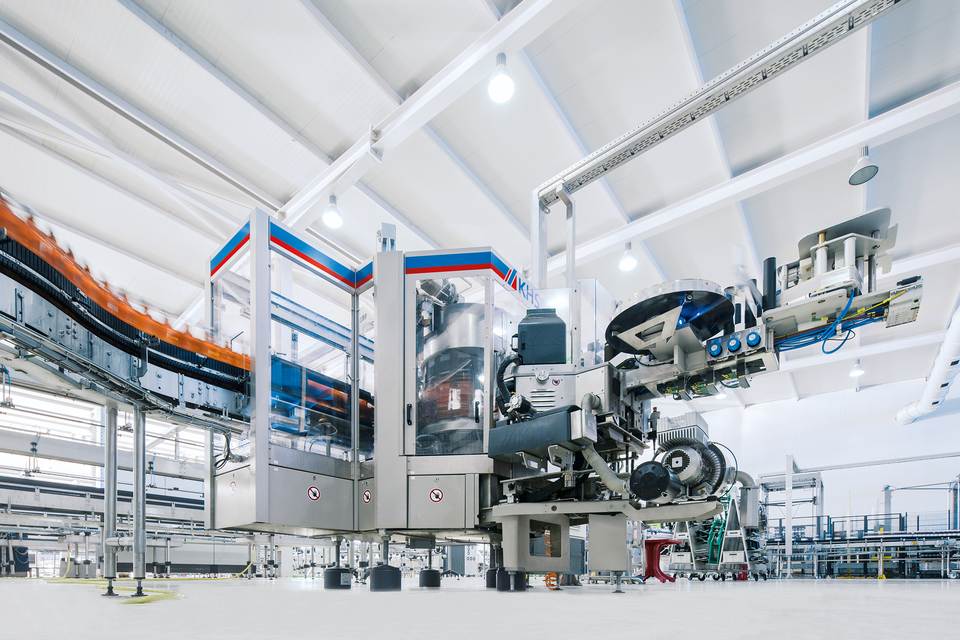

Despite this, PET and glass bottles and kegs generally play a greater role in the range of containers the company fills. Of all its products 60% is filled into PET bottles (chiefly 2.0 and 2.5-liter containers), 15% into glass bottles and 13% into kegs (with cans accounting for 12%). The company exports to ten countries. The question thus arises as to how a company only founded in 2012 has managed to become so successful in such a short time. Chocheli sees it like this. “Our top priority is to provide the best quality beer. This is why we invested in KHS technology. We’re extremely grateful for each and every one of our KHS lines and I believe that they and KHS’ excellent service all play a major part in the success of the brewery.”

Entrepreneur profile

The man who opted out, only to start up again

If you come from the mountains, you’re no stranger to the ups and downs in life. Tsezar Chocheli has also known about the art of brewing since he was a child; the current owner and manager of the Georgian Beer Company grew up in the mountains of Georgia, where making beer has a long tradition. In the distant past beer even used to be considered a holy beverage.

Exit: sale of the companies

But then the political situation changed. During the South Ossetia War Lomissi Brewery was expropriated. In 2008 Chocheli also sold the second brewery he had founded just two years previously to a large foreign brewery group with whom he committed himself to not start any more activities in the brewing industry for three years. During this time he instead built up four new companies in the candy, laundry detergent, gypsum, and cement industries.

New start: the Georgian Beer Company

Once the three years were over, Chocheli announced that he was going to open a new brewery which would start production in nine months. There was much surprise when the Georgian Beer Company did indeed open for business after nine months in the spring of 2012 – with a capacity of 450,000 hectoliters per year.

In 2012 it sold over 200,000 hectoliters, turning over about 320,000 hectoliters in 2013 and making the Georgian Beer Company the current number two among the breweries of Georgia with a market share of 35%. This year (2014) Chocheli is aiming to hit the 450,000-hectoliter mark. The company has already begun increasing its capacity, in part with the help of KHS machinery. Tsezar Chocheli can already envisage “the next step up to 660,000 hectoliters. Our vision is to become the leading producer of beer and non-alcoholic beverages in Georgia."

A year ago KHS delivered and installed the following lines which all very quickly gave the Georgia Beer Company a number of considerable advantages (a turnkey non-returnable glass bottle line for beer and soft drinks with an output of 27,000 recently went into successful operation):

The keg line

A compact Innokeg CombiKeg kegging line (with an output of up to 90 kegs per hour) based on the well-established principle of rotary processing that KHS has been constantly further developing for several decades.

Key features

- Pulse cleaning for extremely careful sanitizing

- Fast, gentle, low-oxygen, and low-CO₂ racking process

- Capabilities for racking Petainer® kegs

The can filler

Incorporated into an existing glass line with an upstream rinser and conveyors.

Key features

- The Innofill DVD filling system (30 filling stations) fills cans and the utilizes machines from an existing glass line

- The can line and conveyors can be removed from the glass line and placed in a separate canning line

- The system is able to fill standard cans as well as sleek and slim cans

- Rapid changeovers thanks to quick-change devices

- Maximum filling accuracy through electromagnetic inductive flow metering

- Low-oxygen filling

- Can be used for beer and carbonated soda pops and still water

- Says Tsezar Chocheli, “The most important machine on a bottling line is always the filler. And KHS has the best filler in the world.”

The PET line

The PET turnkey line has capacity of 22,000 bottles per hour.

Key features:

- The highlight is the InnoPET BloFill stretch blow molder/filler monoblock

- The sanitary room is equipped with filter systems

- Extremely sustainable bottle production with low energy consumption (up to 25% lower than with the previous series)

- Near infrared (NIR) Reflexx heater halves heating times

- Servomotor-controlled stretching process: costs and materials optimized down to the last tenth of a gram in weight

- High process stability

- Flexible filling of beer or carbonated or still non-alcoholic beverages on the Innofill DVF

- Operator-friendly inspection technology that can be expanded

- Compact Innoket 360 S labeling machine with perfect accessibility

- Extremely gentle packing and palletizing processes

- Plastic carrying handle on each bottle makes big bottle handling easier for consumers and retailers

- The Innopro Paramix C dosing and blending system enables over 1,000 recipes

Meanwhile, brewery boss Chocheli has set the course for the future. “We want to become the biggest producer of non-alcoholic beverages and beer on the Georgian market.” “I think we’re very close to achieving this goal and could do so this year.” Some things happen very fast in Georgia.

Your contact on this topic

Oliver Schneider

head of Regional Center Sales CIS

KHS GmbH, Bad Kreuznach, Germany

Phone: +49 671 852-2623

Email: oliver.schneider@khs.com

Ivan Zabun

area sales manager for MZ Europe/CIS

KHS GmbH, Tbilisi office, Georgia

Phone: +49 170-7687210

Email: ivan.zabun@khs.com